Sometime last year I took a serious look at one of my vehicles. I started this project, but it’s been stalled for some time as I tried to work through some details.

I leave them out all year long and the weather takes its toll.

So, I could strip it and repaint it, but I’m eventually planning a fire house in my town, although who knows when that will be.

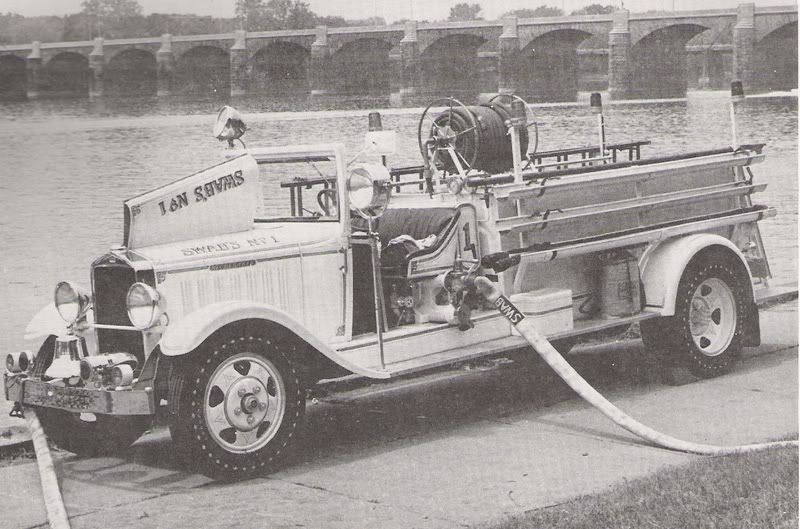

Why note make a firetruck? Well, it’s a small pickup. It’s a Solido 1:19 1936 Ford pickup. It doesn’t really look like a firetruck. Hmm. Not that I really know what a firetruck really looks like, but that’s never stopped me.

Out comes the dremel!

Firetrucks back in the day did not come with a roof. Off with the roof! And the paint.

But, it’s a bit too short. Get out the Dremel again. I cut the fender section (there is no separate frame) in two and put in some brass sheets and strips to lengthen the whole thing.

I also had some COPPER sheets that I soldered together to make a bed.

Starting to look more like a firetruck, but here the project stalled out as I really couldn’t figure out what to do with the inside of the body.