nice work so far Dan! Maybe if you didn’t wear a welders helmet, the chicken that got in and desecrated your wall panels would have been seen!

I’m getting plenty of practice tonight, Pete.

Weekend update: All the basic building structures (walls) have been welded together. That process will be much better in the future because I will make allowances for the weld in the design. The welding seems to be very sturdy and at least as good as glue but much quicker, more or less instant. I got the flooring down for the second story. The 100% 3D printed structure is now down the toilet. I chose to use wood for the flooring so it would match the decking that the entire structure will sit on. I have decided to print the siding. I wish I had made that decision earlier cause I could have printed just the siding as I am doing now and not printed the stud walls. Oh well, we live and learn. All the doors and windows have been printed. Other than the roofing, more on that in a minute, the siding is the only thing remaining. But that is still almost 100 hours of printing left. All in, I will have almost 300 hours of printing in this project. as I said early on, this is an experiment and although I’ll have a nice, quite large building when I’m done, I don’t think 3D printing in its current state is an effective way to build these type structures. I watch as other builders cut walls out of plywood, sintra, pvc, etc, glue them together put some siding and roofing on and they’re done and have I very nice building. I know I over simplified that process, but you understand what I’m talking about. I think 3D printing is ideal for details, one off parts, maybe even a small structure that can be printed all at once, but not something on this scale.

Roofing, I’m still undecided on the roofing material. I’ve toyed with some type of tile as you’ve seen in this thread but I’m not happy with the results just yet. I haven’t abandoned that idea but I may end up with corrugated tin or some type of rolled roofing simply because of time, we’ll see.

Wood flooring

Siding

Thanks for following along.

Dan,

That wood flooring is amazing. That is the most realistic 3D printing I have seen.

This is cool. The engineering that needs to be done to get all that to print and fit together is remarkable

The Inspector may object to the flooring separating the two levels, when it should fit within the walls.

Too bad I don’t have any energy for my own build…(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

John Caughey said:

The Inspector may object to the flooring separating the two levels, when it should fit within the walls.

Too bad I don’t have any energy for my own build…(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

John, We’ll call it the sub-floor and he won’t know the difference (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif)

I hate you’re not feeling well, John. You’ve been through a lot here lately. Wishing you better days, prayers a comin’ (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-smile.gif)

Dave says 3 weekends left.

What me worry?

John Caughey said:

Dave says 3 weekends left.

What me worry?

Might want to start, John … Dave says we only have 2 weekends left, now (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cry.gif)

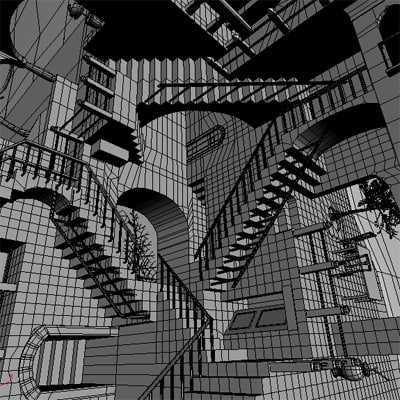

One more update before I call it a night. I’ve got the stairs and landing on the front modeled and ready to print. Stairs and landing are a single unit and will be printed as one piece. Railing on the landing and the 2 support posts will be another print and the final one will be the railings on the stairs.

Soooooo… What ya gonna do if the printer goes down on ya… Seems like you have been running it non stop for weeks… Pushing your luck?

Are you sure this isn’t your napkin drawing?

that thing gets crazier looking all the time.

think Hogwarts’ moving staircases, Dan might get it all printed, but will it get assembled in time is the big question

Dave Taylor said:

Soooooo… What ya gonna do if the printer goes down on ya… Seems like you have been running it non stop for weeks… Pushing your luck?

Well, we would just have to extend the challenge until my new printer arrived (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-tongue-out.gif)

Dave, that’s actually crossed my mind, but I’m at a point now that it would simply be a matter of covering the thing with wood or tin, all the framing parts and doors and windows are done. I can assure you I can cut the needed wood a lot quicker than the remaining print time (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-smile.gif)Yes, other than a few idle hours from about 12 noon each weekday ( I usually start a 4-5 hour print in the mornings before I leave for work) until 5:30 or 6:00 in the evening its run nonstop since January 11 and probably will continue for another week, so yes I’m pushing my luck. But hey, this is a challenge isn’t it?

Pete Lassen said:

think Hogwarts’ moving staircases, Dan might get it all printed, but will it get assembled in time is the big question

you mean all these parts, Pete?

Why hell no, he won’t get them all assembled, roofed, and painted in time … were we supposed to get finished? I didn’t see that in the rules (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-tongue-out.gif)

All the modeling is finally complete … is it time to start building yet (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-yell.gif)Here is the final model with siding but no roofing.

I know you’re getting tired of seeing photos of a model, but other than the few build photos I’ve posted, that’s about all the progress I have so far. I’m at a point now where I need the remaining printed parts before I start welding more parts together. The remaining sections are somewhat complicated and I need to test fit all of it before permanently attaching. That won’t take long once the printing is complete. Only 49.5 hours left. Some print statistics to date: Total print time - 238 hrs, total filament used - 4,653 feet (will be more than a mile when complete).

All of the timber for the deck has been milled and will start putting it together tomorrow. I’ve punted the slate roof idea, just can’t get anything that looks right so I will use corrugated tin. Speaking of tin, I’ve started another project that involves tin. Look for that thread soon.

That’s all for now.

Dan,

This is just hands down cool. When I think of all the sub-assemblies resident in the files for this project, I see virtually an unlimited number of projects you could generate with the work you’ve done. I am pretty sure, as I mentioned, this is the future of modeling, whether for full kits or detail parts. Imagine if some clever guy or gal, for instance, started marketing a conversion kit for LGB’s Stainz or some other “starter pack engine.” Send the cash, donwload the file, print, assemble, paint.

Build on!

Eric

John Passaro said:

Are you sure this isn’t your napkin drawing?

something close to that is one of my next projects. plan to populate it with aliens, wizards, and weird characters. whether or not I can build the thing without injuring myself or landing on heavy duty psych med’s is another issue.

Dan this is one hell of a build using newer equipment and stretching the limits of expectations. You are not the first to go here and while getting one great repeatable model you have given the rest of us a glimpse into 3D printing on a massive scale. Not only can others follow along but if you share your files they can have the same building if so inclined.

Fantastic work and I for one am looking forward to the finished entry.(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

Eric Mueller said:

Dan,

This is just hands down cool. When I think of all the sub-assemblies resident in the files for this project, I see virtually an unlimited number of projects you could generate with the work you’ve done. I am pretty sure, as I mentioned, this is the future of modeling, whether for full kits or detail parts. Imagine if some clever guy or gal, for instance, started marketing a conversion kit for LGB’s Stainz or some other “starter pack engine.” Send the cash, donwload the file, print, assemble, paint.

Build on!

Eric

Thanks Eric. It has certainly been a learning experience. As others here on LSC have demonstrated, 3D printing can play a prominent role in our hobby now and in the future. Not sure what I am doing is the perfect use of this technology, but it works. I could have spent half the time and filament had I made all the design choices up front. I started out planing to use wood or tin for the siding so I printed the stud walls. But, then I changed my mind and chose to print clapboard siding and there was really no need for the stud walls other than to mimic the real world and add a little character to the building. One off details, parts, loads like Bob is doing or small structures are ideal for 3D printing.