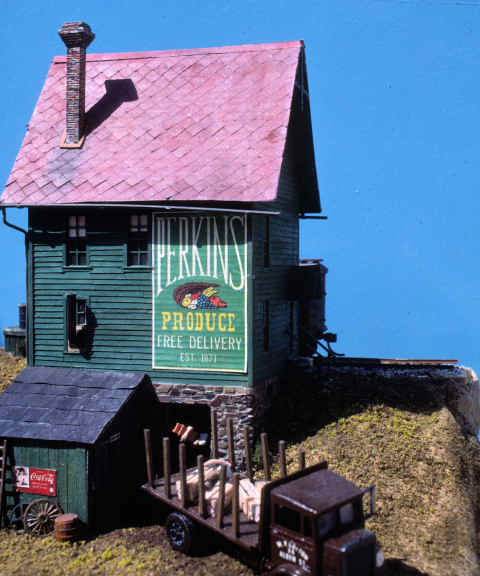

Back in December 1974, Model Railroader published a how-to article on building Perkins Produce House. It was a great article; it included plans as well as very detailed step by step directions. It was one of my first scratch-built models. The magazines at that time really encouraged me to build models from scratch, and I learned a lot of techniques from them. I built this in HO using IBM data cards for the siding.

I fondly remember it and once Doug suggested that one of my sidings should be for produce, I resurrected my memories and ordered a copy of the magazine. It was time to build the 1:20 version! The first step is to build the windows. I need 5 of one type, and one of another. I decided I’d scratch build them, so I created forms using some scrap wood.

Next, I used .060 x.060 styrene for the muntins, and .125 x .060 for the frames.

The pieces were glued in place to form window pieces. Then, I glued some .250 x .060 to make the window frame itself.

Soon, I had the inner pieces built up.

When I built Matheson Textiles, the large acrylic pieces were protected during shipping by these plastic pieces - they’re double wall construction, with vertical beams going between the walls. Naturally, I kept them, hoping I could use them in the future. You can cut the material with a sharp knife, but I used my trusty Micro-Lux scroll saw to cut the window and door openings.

I used Weld-On 16 glue to hold the pieces together.

Once the openings were cut, I put the final frame pieces around each window using .060 x .125 styrene.

I used Precision Products aged clapboard siding and glued it in place using Welder - a contact cement. The windows were there glued in place.

The base was some cut stone from Precision Products. It was painted with a wash of alcohol and India ink. (The door still needs a coat of paint.) I created the sign using Paint Shop and then printed it on “papilio” inkjet white waterproof vinyl. I sprayed Krylon Matte Clear on top of it.

I went over to the paint store and got a quart of exterior green latex that I thought might be pretty close to the color I printed.

Next, the roof…