A while back, Doug Matheson (from Canada) and I discussed some building flats that would be positioned on the side of his shed. I offered to build the Rossean Hotel and I’m hoping to have it complete by ECLSTS.

It started as just some ideas my choice of architecture … roof and window, etc … something built after 1900 (the era is set in the 20s) … brick sounds good … a downtown hotel so not too run down

But there were a few “rules”. Doug wanted a 3 story building, and it had to be fairly sizable - he wanted 50’ of width.

So, I got some 1/4" clear plexiglass and 1/8" foam pvc board - 20" x 30".

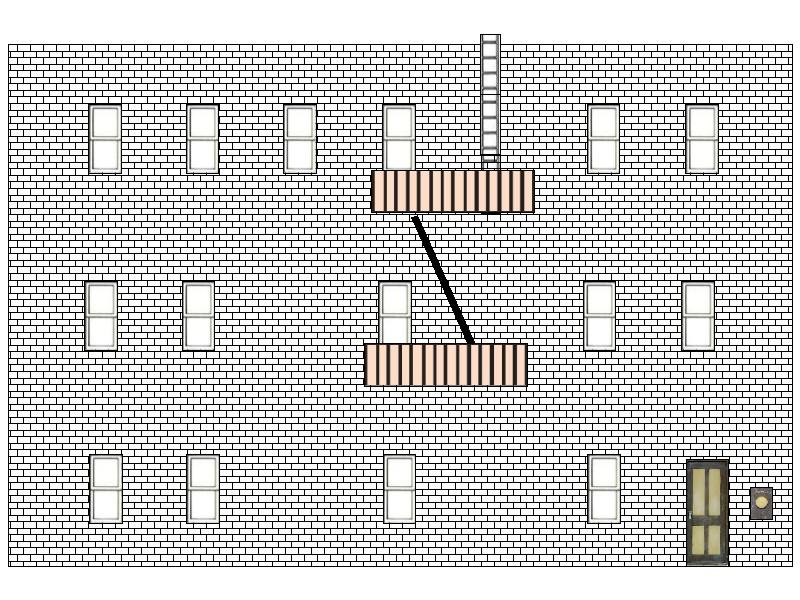

My initial design calls for 15 windows, a door and a fire escape.

I made the windows using styrene strips and a wooden jig

Fire escapes were first framed using some square brass tube.

I used some grating I got from Plastruct for the floor and the railing.

The railings were a bit fragile, so I reinforced them with some brass angle. The platform on the left will be the lower platform and I made the ladder frame out of brass.

I think most of the hard work has been done, so I should be done by the show. I’ll give it to Doug at the Drag and Brag, as he will be traveling back to Ottawa on Saturday.