Looking good Jim, great transformation.

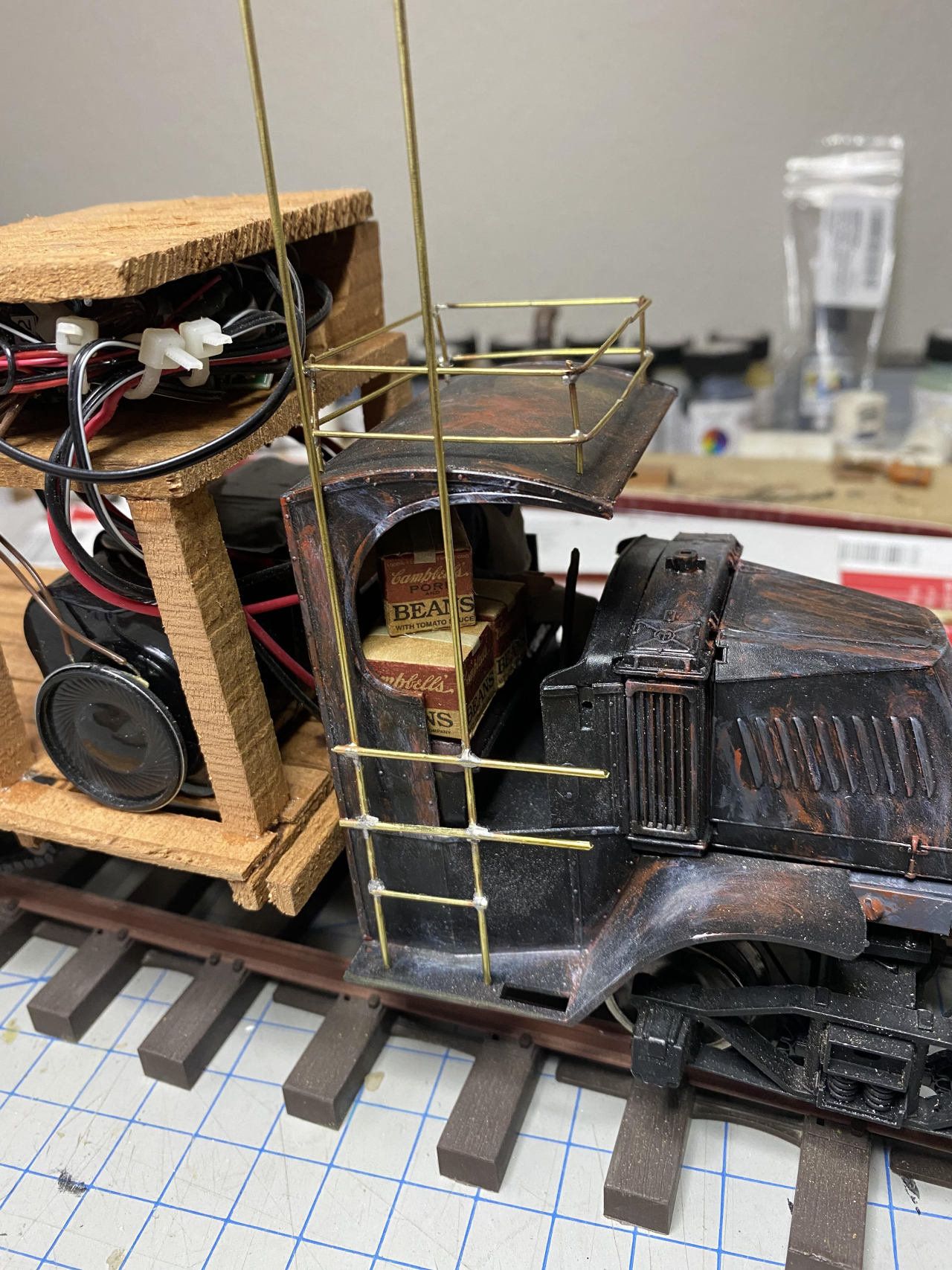

“With that radiator placement, the driver can heat him up a can of beans while riding the rails.”

AAAAAAaaaaaaaaaand that way he will never run out of GAS!!

Weaving, dodging, and plugging my nose, David Meashey

Been working on a cowcatcher for the front of the railtruck, using this image as an inspiration: [link] (sorry, it’s a stock photo and not embeddable).

First, I cogitated and asked the evening chat guys for suggestions. Hollywood suggested using brass tubes, smashing the ends. After experimenting that seemed good. Fred suggested that most people make the rod diameter too large, but I’m afraid I only have 3/64 brass tubes on hand and wanted to make progress here, so I am afraid I will not be able to be as thin as would be good (3/64 is about 1 1/8" in the prototype which is a hefty steel rod).

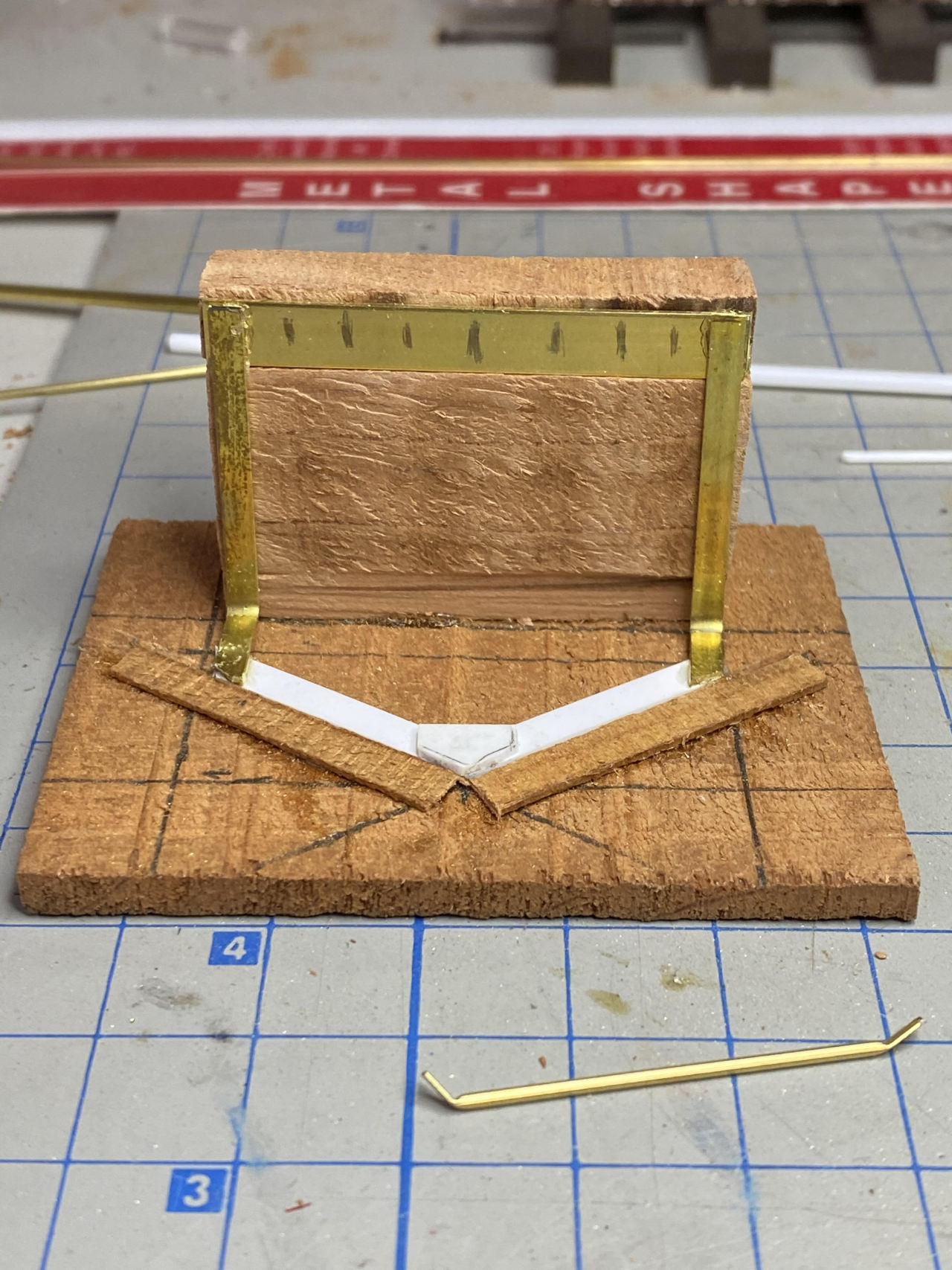

After all that thinking I ended up making a jig so I could build this thing:

And most of the way there:

And mostly primed:

Tomorrow I’ll get it painted and installed and then figure out what else I can do in my precious time off here…

Cheers!

Awesome, Jim!!!

Nice work, Jim. Nothing wrong with making something extra strong, it’ll just better protect the front of the truck.

Jim,

This 'truck is just awesome!

Eric

Looks like you nailed it again Jim. Size on the tubing appears spot on. (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

that is so cool Jim. Your tastes and mine in railroading are so similiar. I love this build

Before painting the cowcatcher, I decided to build the roof rack/ladder, because they should be painted the same color and I am too lazy to clean my airbrush twice…

This is the inspiration for the roof rack, from Ray Dunakin (check the first post in this topic for the link to his awesome rail car):

Boy, was this a pain in the a$$. I clearly need to up my soldering/jig game because I had to make up some new cusswords this morning. And I’m not convinced I like what I have.

I made a jig to bend the brass rod to form the main storage rack:

And the rack after soldering. The thing I’m not thinking is correct is the vertical separation of the rack itself (it is too “tall”). But I’m too mad to try to fix it :-). It seems so effortless when Ray does it!

And I’m too busy the rest of the day to finish. Oh well, made some significant progress this week.

Cheers!

Nice work Jim!

I feel that brass is an ideal material to work with as it is so strong, yet can be bent to the shape you want. I really like your use of jigs for assembly as well!

For those of you that have not yet tried it, the soldering is REALLY NOT THAT BAD!!!

To be fair, mostly I wasn’t good enough at holding things in position. It isn’t the soldering so much as me trying to take shortcuts. Silly me…

Yeah, I NEVER take any short cuts when I build as it’s all by the book !

The Book of Rooster chapter 21(this June) verse 69

Jim Rowson said:

To be fair, mostly I wasn’t good enough at holding things in position. It isn’t the soldering so much as me trying to take shortcuts. Silly me…

It’s NOT cheating! (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-foot-in-mouth.gif)

It’s just the only way to make sure things don’t shift when you don’t want them to! I always used a jig - and LOTS of pins to hold everything down. But, when it’s complete it always amazed me at how strong it really was. (And, quite frankly, I was always amazed at how good it looked! (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-embarassed.gif))

Awesome. (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-smile.gif)

Rooster said:

Yeah, I NEVER take any short cuts when I build as it’s all by the book !

The Book of Rooster chapter 21(this June) verse 69

I never knew Roosters could read! (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-foot-in-mouth.gif)

They can peck a book open, but their reading comprehension is VERY low…

Time to work on trains: priceless!

Today I got to build a ladder to provide access to the roof rack on the railtruck. To start with, a jig:

And a test fit as I am partway along:

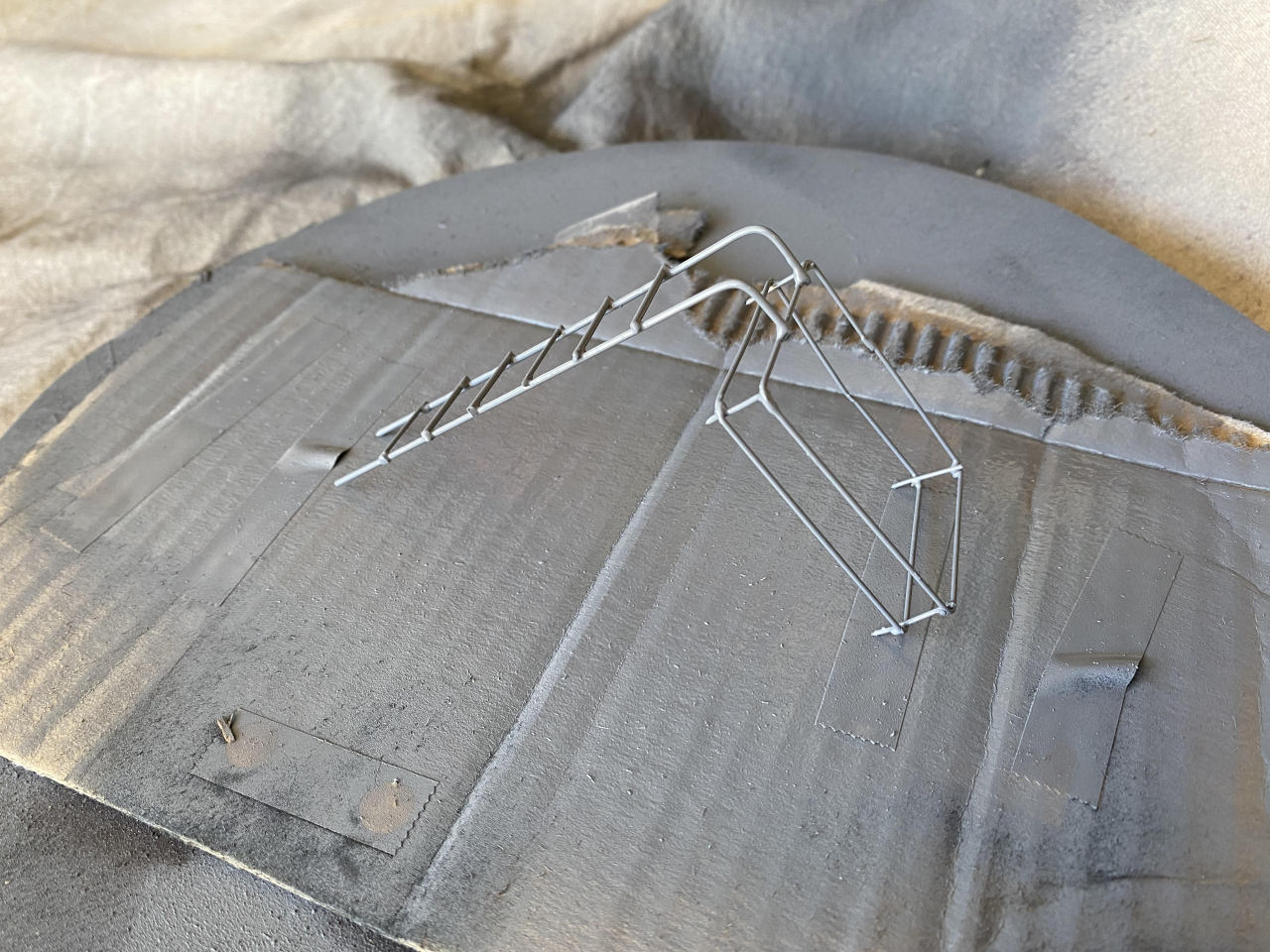

Here’s the ladder “done” (though the top part needs to be trimmed):

And, after trimming and priming:

This is very similar to the way Ray Dunakis did the ladder on the back of his railcar (see the first post here for a pointer to that fine build).

Cheers!

Very nice work. Takes a steady hand.

Doc