I’ve been gathering stuff to build a roughly bashed together railtruck based on a 1926 Mack truck with some freight and some passenger capability (i.e. a railtruck combine-ish sort of hack).

I’m inspired partly by Ray Dunakin’s railcar [link]:

and Dennis Rayon’s backwoods Porter [link]:

Hollywood was gracious enough to send me a Mack truck model I can use for this bash:

I had already built one of these [link] and hope I’m ready to bash this similar model into something that actually runs.

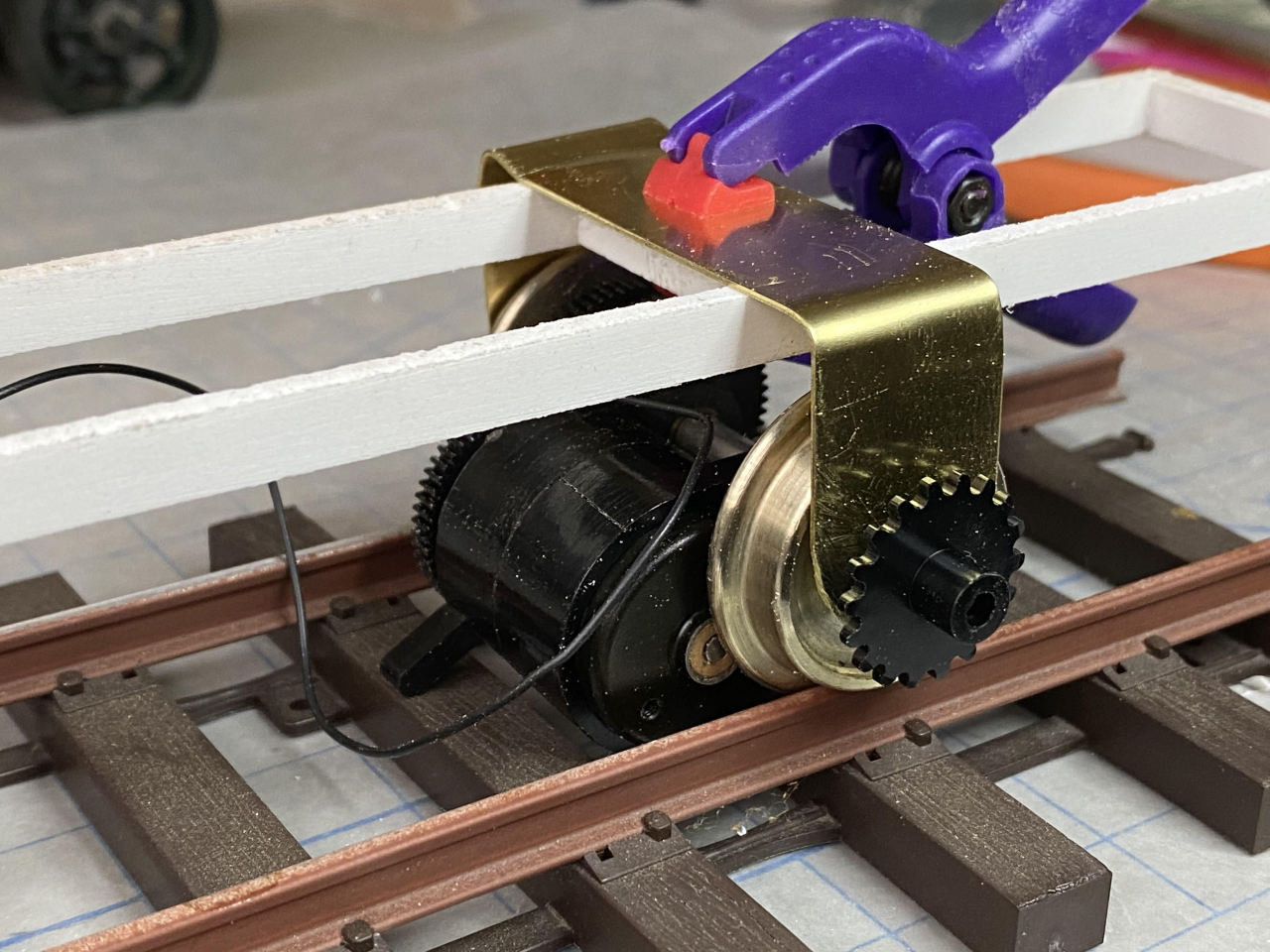

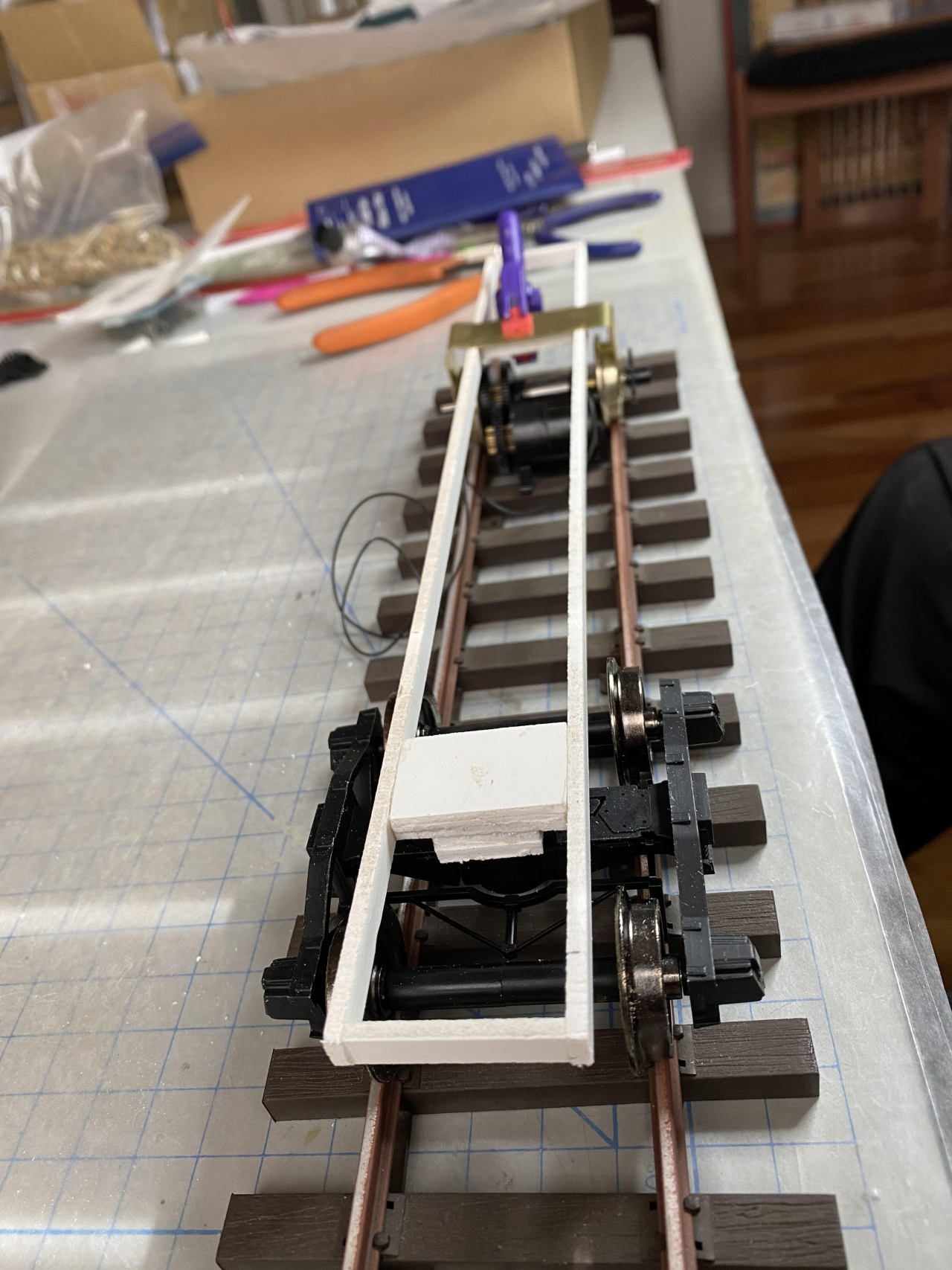

Boomer pointed me to an eBay seller that had a Northwest Short Line #1 gauge Magic Carpet drive, and I’m hoping to use that as the motive power. Right now I’m struggling a bit with how to integrate that, and a regular truck, with the frame of the Mack truck, as they are similar widths. Hopefully I’ll figure that out soon.

It would also be great if I can have a chain drive (maybe not actually doing the “drive” part but at least animating, and I’m experimenting with a MicroMark set of sprockets and chains:

Wish me luck! Suggestions are welcome!