It sure is, John. That’s why I need to make another doohickey to hold it at the right angle. Tomorrow’s task…

Might be time for a Thing-a-ma-bob, if you’re getting too many hickies.

I have a dingus too, if that helps!

Jim Rowson said:

I have a dingus too, if that helps!

(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-embarassed.gif)

Dirty Dingus McGee - wasn’t that a 1960s or 70s western movie? My Dad was a big fan of Westerns. And didn’t it star someone who was famous for some other form of entertainment?

Okay off to look in Google.

Dirty Dingus McGee= Frank Sinatra

Jim,

I feel you. I think I am going to have to break down and make a frame much like you are for mine. Trying to make things fit where they were never intended to go in a small model is a bit rough. You will get it.

Jim, just make sure your doo hickey is not slonchwise, as my uncle used to say. I once asked what slonchwise was and he said the opposite of antigoggling!!! Thanks Uncle Bill!

Jim, I really like the looks of this build so far. A rail truck is one of the few missing pieces of motive power I would like to have on the roster. Watching with great interest.

I hate it when my doohickey gets slonchwise (hmmm, I always thought it was slaunchwise, but who’s counting? neither one passes spellcheck).

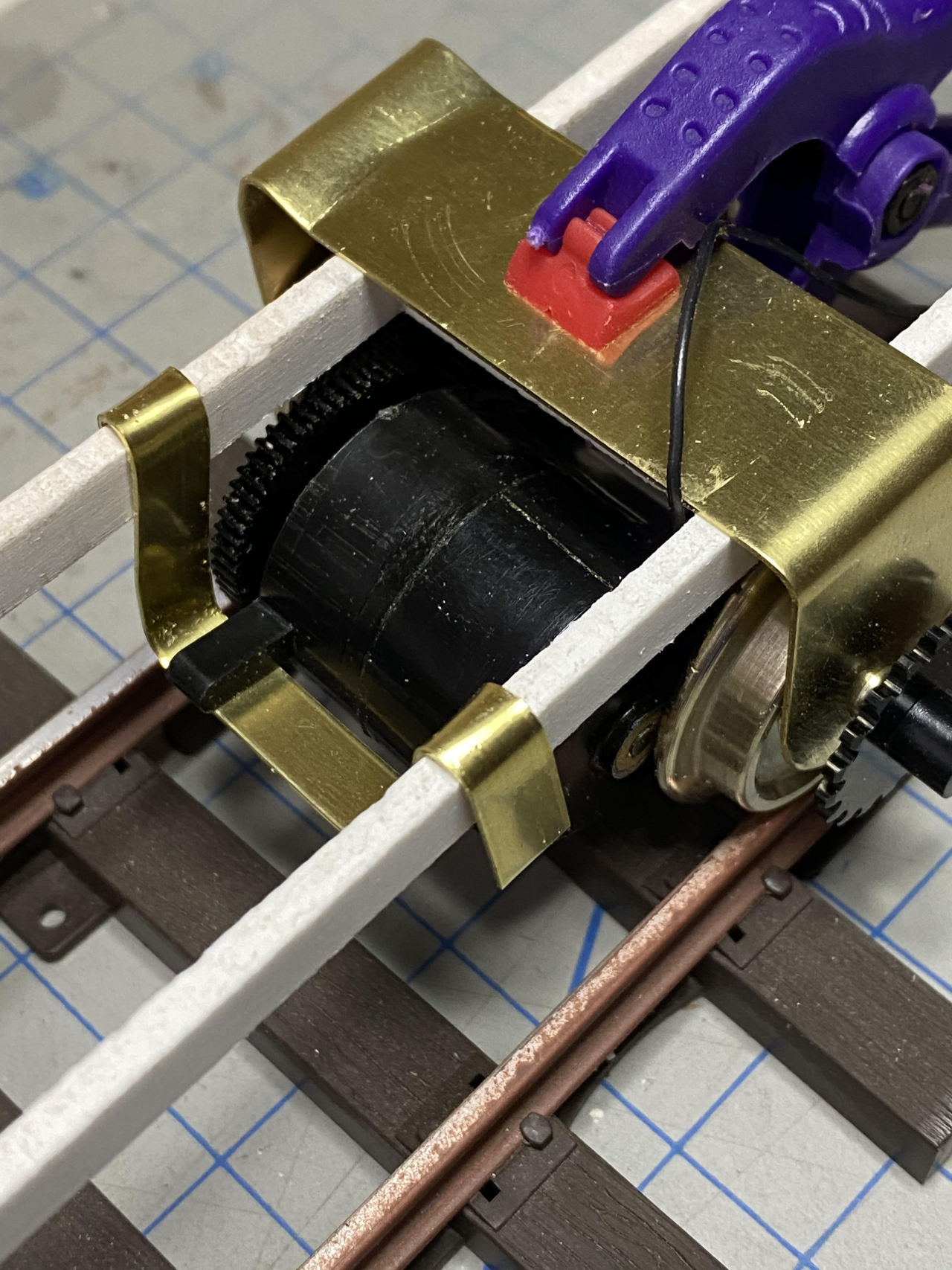

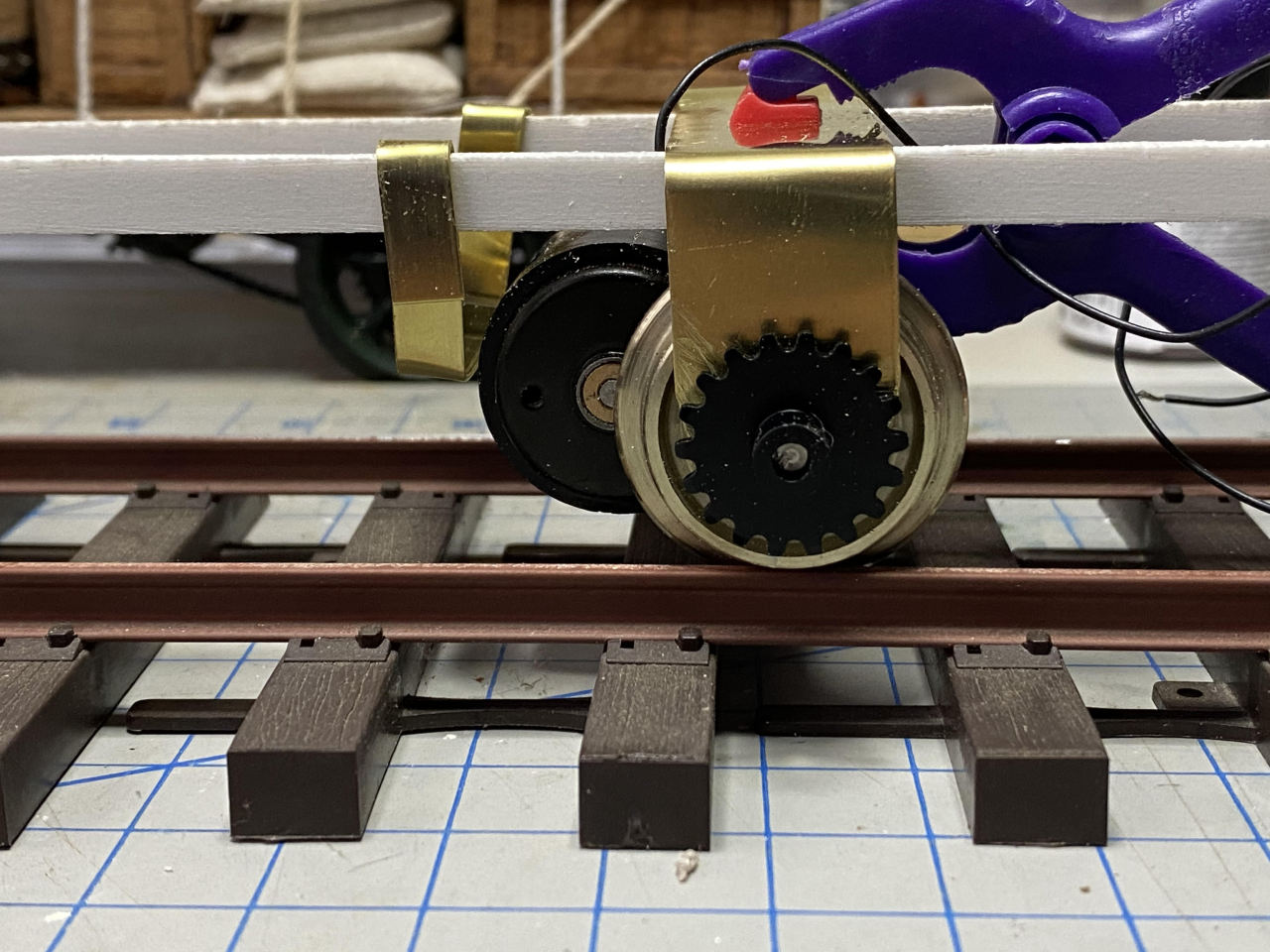

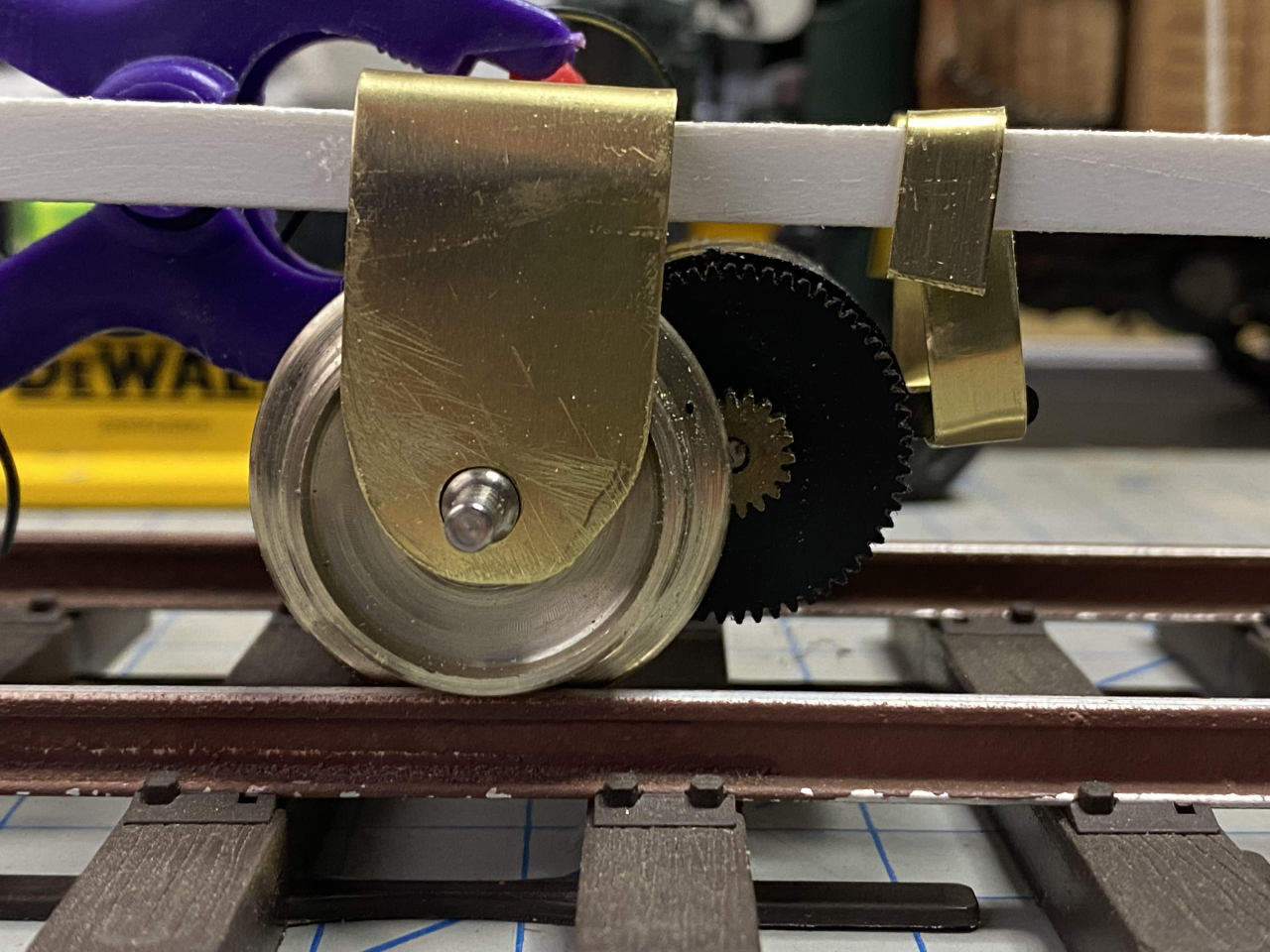

Today was dingus day: building a little bracket to hold the motor at an angle. This is just the basic strap… I need to also add a piece to hold it firmly in place on top of the plastic tab that is obviously there to help hold the motor in place (I hope!). Not show here, I also added some trim to make the frame be parallel to the track (i.e. straight!). Waiting for glue to dry and have some screws and bolts on order so I can decide how I want to actually attach this firmly.

Before I post pics, I have a question for this highly experienced audience: how much should I worry about making this motor be removable (i.e. replaceable)? Or should I just go ahead and make this a permanent installation?

OK, pics:

Happy stay-at-home!

Jim,

Based on a well-grounded lack of experience, I am all for making the motor removable and replaceable. You never know where a good idea in concept might translate into a bad idea in practice!

Eric

Eric: I would LOVE to make it removable, but I’m not so totally sure I know how to do it. I’ll keep noodling at it. Thanks for encouraging me (I think?)…

Jim Rowson said:

Eric: I would LOVE to make it removable, but I’m not so totally sure I know how to do it. I’ll keep noodling at it. Thanks for encouraging me (I think?)…

Even if it were removable, what are the odds of finding a replacement If it broke.

doc

How easily removable are the motors in your locomotives?

Perhaps some disassembly required(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif)

My thought would be to run a brass flat bar on the under side of the frame at your mount location and

through bolt the mount to the frame to reinforce the frame at what will be a stress point for the frame.

Make a sub assembly for the motor and Wheels. I think you are too dependent on your foam frame. I’d rather the frame merely hold it true to the track than holding moving parts in alignment.

Combine that with Marty’s reinforced frame ideas …

I think your motor is hanging a tad low…

Jim, these kind of drives need to be very solidly mounted so they can’t rotate around the axle - which they will try to do instead of turning the wheels. The attached pic shows a Fosworks drive, just like the NWSL (and also no longer available,) with the big plate that fit on the motor lugs to stop it rotating.

Just for info, here’s a pic of the small Bachmann truck that is available from the Parts dept, if they ever re-open. I used it on the front of my railtruck. Those are small Bachmann 26mm wheels, and the curly spoke wheel was just there to be looked at. The bolts are holding the pickups in place and were trimmed.

Thanks everybody for the encouragement and ideas. I’m thinking more about how to mount this puppy.

Pete: I had already figured out that it would try to rotate itself without a good solid mount. Clearly what I’ve done so far isn’t good enough for that but I was working towards that kind of mount.

John: Your advice is well taken. Thinking about how to make this be a separate, stiff module that can be attached to the frame. Would also help with Pete’s advice.

Rooster: I like your idea, with Rick’s modification. Worried that my frame is too thin for such an attachment but I have a cross brace that I can screw through hidden under the brass doohickey.

Again, your advice and ideas are really valuable to me. Thanks!

Jim Rowson said:

Worried that my frame is too thin for such an attachment but I have a cross brace that I can screw through hidden under the brass doohickey.

I agree it is too thin as a stand alone but I was thinking that the model body screwed to the frame will give it more than enough strength however we did not get that far yet. I only answered you on how to make it removable and how I would approach it . An automotive uni-body frame is a flimsy worthless piece of crap until you put the body on it .

Was thinking when you put the body on and attach it to the frame even with some 1/32 " brass pins into the 1/8" PVC frame I bet it would be stiffer than a wedding night rooster! However this is just my experience and sometimes one needs to think outside of the box.

Now …if the model body cannot be attached to the frame or it’s (body) too flimsy then my thoughts are out the window. Only stating my approach from what I’m seeing from you’re,your (spelin) pictures that you are graciously sharing and I’m certainly enjoying.

Keep up the good work and badge it Amtrak when finished (any paint phase of you,you’re,you are choice)!

(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)