I would say maybe just lower the building by cutting out a course or two, overall a warehouse like this has better looking proportions being long and low, but then that would also lower the canopy probably right into the top of your freight cars. So your back to just lowering the door sill heights and leaving everything else as is.

Your build will be great. I agree with Vic…and I hear your trepidation about the size. I wanted to avoid what Bruce and you were saying about the basement, too. As I mentioned in my build log, this is why my engine house went from two tracks to one track. Here was the original enormous footprint ! Yikes !

Thank you all for the advise. I’m quite sure it was a measurement error. Everything looked good on the scale drawing, but when I laid it out on the substrate the door bottoms fell one course too high; which pushes everything up one course including the overhang. I planned the overhang to just clear the roof of my 45 Ton diesels which is my mobile clearance gauge. I can’t afford the block to keep the windows high and the overhang above the door height as currently laid out.

Yes, cutting the height by one course would be the simple way out; but I laid it out in pencil and have plenty of erasers

John if you need a few extra stones, I have all 6 of the real long ones and about a handful of the 1x2 size… shoot me a message, I will mail them to you

Thanks, but if I counted correctly I should have just enough - and I decided to make the windows bigger, so less stones there too.

Not sure I will have the windows before the deadline. My router guru said he can make them, but it has to wait to be tacked on another job. Not sure when that will be.

Pete Lassen said:

John if you need a few extra stones, I have all 6 of the real long ones and about a handful of the 1x2 size… shoot me a message, I will mail them to you

Actually Pete, if John doesn’t take you up on the long pieces I think I could use them; I’m not sure I have enough for all the window sills I need.

John Passaro said:

Pete Lassen said:

John if you need a few extra stones, I have all 6 of the real long ones and about a handful of the 1x2 size… shoot me a message, I will mail them to you

Actually Pete, if John doesn’t take you up on the long pieces I think I could use them; I’m not sure I have enough for all the window sills I need.

You are welcome to them John - Looks like I may not finish in time due to production delays at the window factory!

Not much progress to report. Long hours at work have left little energy or time for this project. I did get the windows designed and handed of to the CNC router guru at work. Not sure if there will be a chance to run them in time to install by the deadline. I’d like to do CNC routing for the doors to if I can talk him into one more off the clock project.

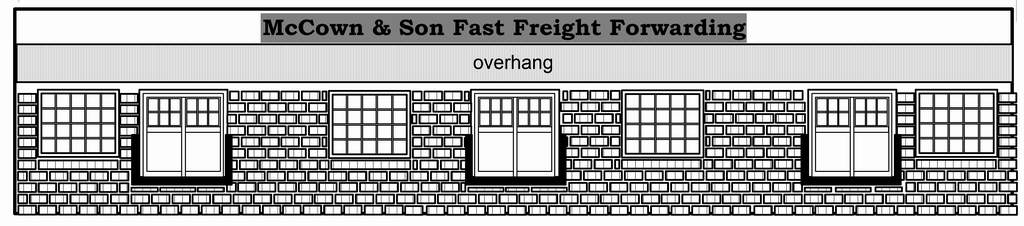

I was holding a print out of the new window design sideways and decided that I liked them that way better; thus raising the sill as previously suggested. I also adjusted the plan to fit the block, rather than trying to fit the block to the plan. I am about 1 scale foot narrower overall. Also updated the Visio drawing to get the block installation plan documented…

I’m taking my block supply to work with my for paint using the Lou method. At work I have a big indoor paint room so I won’t have to smell up the house  I plan on grouting the block using some regular tile grout that I have in-stock.

I plan on grouting the block using some regular tile grout that I have in-stock.

Drew up a door. Loosely based on the freight doors on the extant New Haven passenger depot at Brookfield, Connecticut. Here is the inspiration…

And my interpretation…

The prototype opens by sliding left. In my design that would cover a window. I have the height that the door could have been designed to open up. Mine won’t open, but a suggestion of lift to open will be made with a handle at the bottom.

thats a nice looking door. You have my approval.

Daktah John said:

The prototype opens by sliding left. In my design that would cover a window. I have the height that the door could have been designed to open up. Mine won’t open, but a suggestion of lift to open will be made with a handle at the bottom.

Honestly if you haven’t already started perhaps you might consider taking out one window on each side of the center door and then centering one window on both sides. That would allow all doors to slide open and the center door could slide both ways (if they were hinged I could say swing both ways).

It’s so easy to make a sliding door like that operate. Then you could easily and quickly open them at night for unloading moonshine ,firearms you know stuff like that.

" Rooster " said:

Daktah John said:

The prototype opens by sliding left. In my design that would cover a window. I have the height that the door could have been designed to open up. Mine won’t open, but a suggestion of lift to open will be made with a handle at the bottom.

Honestly if you haven’t already started perhaps you might consider taking out one window on each side of the center door and then centering one window on both sides. That would allow all doors to slide open and the center door could slide both ways (if they were hinged I could say swing both ways).

It’s so easy to make a sliding door like that operate. Then you could easily and quickly open them at night for unloading moonshine ,firearms you know stuff like that.

That would be very cool; but operating doors aren’t in the plan. The frame and doors will all be on piece of PVC; details carved out by our CNC router at work; unless I decided to get ambitious and build them up from styrene by hand. Perish the thought.  I need to take a block count of the current print and see if you can talk me in to it.

I need to take a block count of the current print and see if you can talk me in to it.

With many thanks to Lou for the inspiration; I spent a few hours after work painting my stones using his technique. I expanded the palette quite a bit and had a great time getting over spray on the stones from all kinds of odd angles. At first glance it looked like all I did was make kindergarten borwn by mixing all these colors…

But, upon closer inspection, Lou’s magic formula worked!

I just love the multiple colors - looks much more natural than painting a single color…

Thanks Lou

Good looking paint job, John. I like those doors too.

Yep Lou hit a quick winner on the stones. Nice work Jon(http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

" Rooster " said:

Honestly if you haven’t already started perhaps you might consider taking out one window on each side of the center door and then centering one window on both sides. That would allow all doors to slide open and the center door could slide both ways (if they were hinged I could say swing both ways).

It’s so easy to make a sliding door like that operate. Then you could easily and quickly open them at night for unloading moonshine ,firearms you know stuff like that.

OK. I decided the Rooster was right. The doors need to slide sideways. Two windows were eliminated to allow for the end doors to slide as one piece toward the center and the center door will split and slide toward each end. I still don’t plan on operating doors, but this change makes the structure more believable and allows for the operating option. The windows are intentionally off-center in the space between the doors to accommodate the full width of the end doors. Here’s how it looks drawn up…

I took a block inventory while painting and if I’m correct I’ll have just about enough to do this! I was going to start gluing them on today, but hesitated since without the actual windows in hand, cutting openings for them will be risky. That’s my excuse and I’m sticking to it.

That looks much better, John. I think the sliding doors will be more realistic and removing the two windows did not take away from the overall design at all, IMO. The building looks more balanced now.

John

I’m not right or wrong as we all know there is a prototype for everything and it’s your building/railroad your rules my friend! I’m only looking at it from my perspective and I’m no expert on anything.

I think one of the issues that is hanging you up on the configuration is the window balance. Mind you the balance CAN be off if you wish and many applications have such. However you have 3 over 2 on each door glass(making a 6 over 2 total) but you have 5 over 4 on the wall windows.

You could go to 6 over 4 on the middle wall windows then center them. Then drop the end windows to a 3 over 4 configuration and it might balance out better allowing your end doors to split as they were intended to.

Make sense?

Even if it is all machined out on a CNC you can still cut the doors out and make them work.

This post has been reported to the moderator by: Rooster

“Creating more work and beer drinking for the original poster”

Thanks Roos -

I can’t redesign the windows as my Router Guru has already converted my 2D design to 3D for processing. I could change the doors so long as the dimensions don’t change; but I rather like them as-is. What I can do is to drop the widows .25" so that the mullions of the first to window rows line up with the horizontal mullions on the door. If I did that by adding an additional .25" trim around the window it might not screw up the block that I have already dry fit.

Here is what I accomplished today, besides doodling on the computer. Length shortened by about 1 inch; doors and window positions finalized; block dry fit; and final positions drawn on the substrate…

Window and door positions were re-drawn the substrate…

Back to it’s future home for a test fit…

Since everything has now been dry fit, I’m leaning toward leaving it as is and not worrying any imbalance.

Looks Good!

What if you turned the windows and made them 4 over 5 instead of 5 over 4 …just for a little more space on either sides of the doors.

I’ll tell myself to “shut up Rooster”