Not only do I need another industry, but I really need a place to store some of my rolling stock. So, the idea was born for a large building. This one is 42" long by 24" wide. It is designed to hold 2 rows of seven cars each, with a lift off roof providing access. I decided it would be a textile mill. Doug Matheson, from Ottawa, Canada, has been a huge source of inspiration and advice, so I decided to name the textile mill in his honor. I used Google SketchUp to come up with a plan of how it might look.

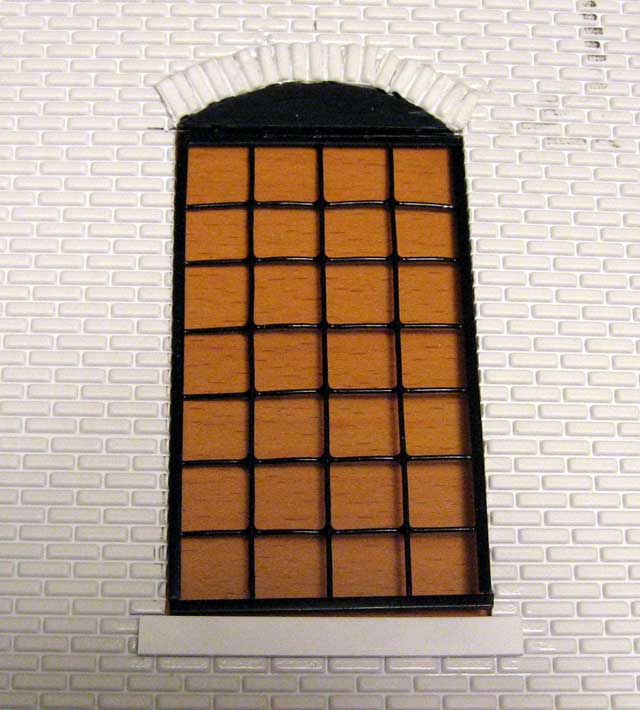

Next, I turned to my mold material. It had been longer than I thought since I last cast anything. It was all separated and about the consistency of jello. Not good. I thought about buying some new mold material, as well as some new resin. Ugh. Even with casting, it would take a LONG time to cast 46 windows. I looked around the shop, and spotted some hardware cloth. Hmm. So, I cut a sample piece and filed the edges smooth. Much easier. I’ve now cut out 46 windows and I’m halfway to filing them smooth.