I like to make working brass hinges; K and S brass tube and wire and flat stock for straps -hinges, 2 shorties on one side and a longer single on the other. Square ends on the tubing so they slide against each other. Make a jig with a depression for the tube, so the strap lays perpendicular to the tubing. Solder. Drill strips for bolts and there you go.

Jim Rowson said: (I’d like to be able to open it).

You already have the technique figured out…just put a pin at the top and bottom of both corners. Then fake the rest with styrene (strap hinges)

Yay, it’s the weekend. I get to work on my trains! Life is good (for the moment).

I’ve made some progress: doors and windows (including “glass”).

Here’s the side wall, notably the door to the upstairs storage area. The door/window downstairs are also done.

And the front wall:

Including an open sign:

Next up: roof!

Jim,

Your kinda a humble dark horse. You are quiet, talk so nice about how much everyone else is doing such a great job and how much you are learning. . .then blam. . . take this. . . you through out a building like that.

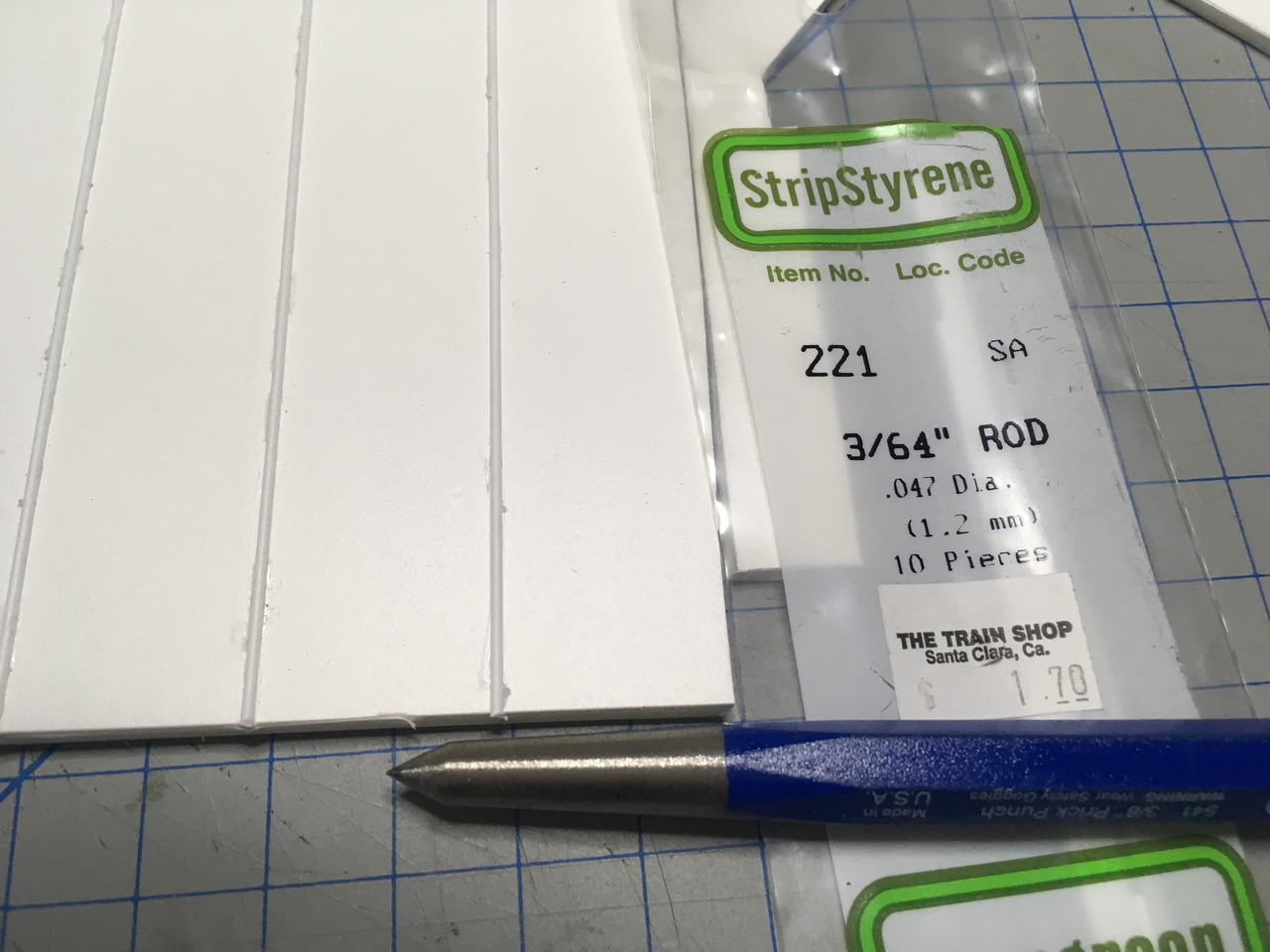

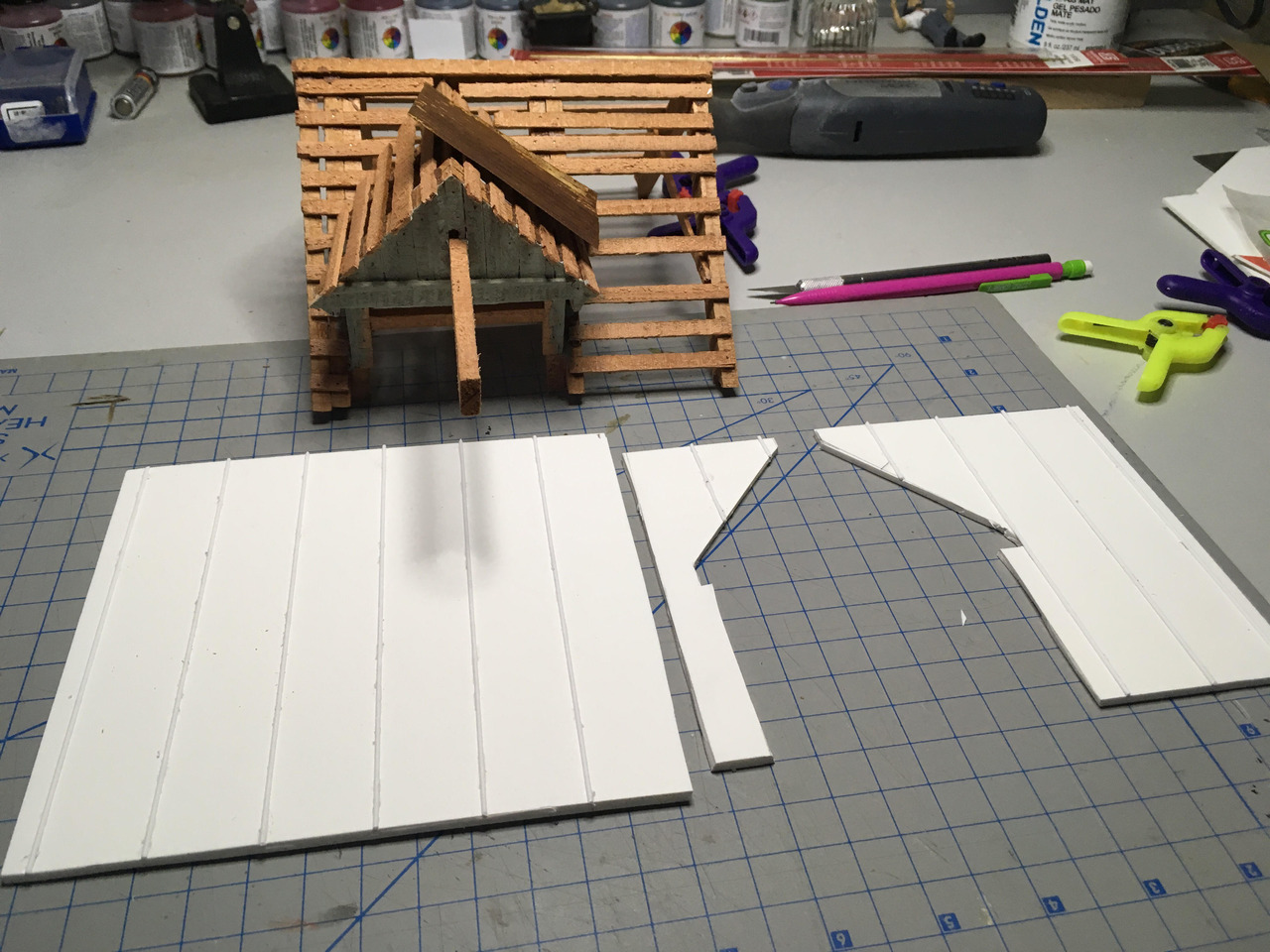

I’m trying yet another new thing: metal roofing. Also trying a different material: PVC (some people buy it branded Sintra). To make the roof, I scribe a v shaped groove in the PVC and then glue in 3/64" rods to represent the seams. We’ll see how it works (advice from a savant here on the site is that it should look good).

And here are the parts of the roof. The dormer, and cap on the roof, will be rusty corrugated metal:

[edited to clarify that this is NOT Sintra, but PVC board]

Yaa, what Devon said(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif)

Looking great Jim, where did you get the hinges, or did I miss that part?

Thanks Rick. I just made those out of brass rod and shim stock. Very freelanced… They sort of work but aren’t real smooth. Probably ok for posing for pictures as that’s pretty much all I will use the door open/close mechanism for…

John Caughey had suggested using rod and tube to build the hinge part but I didn’t have an appropriate size tube so I just winged it by bending the shim stock back onto itself around the rod.

[edit to improve word choice]

Can’t wait to see the roof. From your description, it should look great. And for freelanced, the hinges turned out quite nice.

![]()

Waiting for paint to dry on the roof, so working on the hoist. Got these really nice pulleys from Harbor Models [link], so I added some hooks and loops, including a loop on the underside of the hoist beam:

Now I’m trying to figure out how to get some realistic rope for it. I separated out a couple of strands from some string. But note that it has retained the waviness from being intertwined. Any advice for how to remove that? Or do I need to go hunt for some thinner string? I have some braided fishing line but it looks more like metal cable than rope.

[edited to add the link to Harbor Models]

Hint; When you open a hook, don’t straighten the bend. Pull the end to the side and then you can close it easily after connecting it to the link/chain.

When you try to rebend, you’ll need to go farther so it can spring back some, which leaves a gap.

Carpet thread might be bulky enough.

Try bee’s wax

There is a decent pre-waxed thread made for sewing leather. You can get it a Micheal’s. Should be about the right size. And I m glad this came up because I have some and would make a nice detail for the crane. https://www.amazon.com/284yrd-Leather-Sewing-Whipping-Stitching/dp/B00UV7F8ZY/ref=asc_df_B00UV7F8ZY/?tag=hyprod-20&linkCode=df0&hvadid=198078533640&hvpos=1o5&hvnetw=g&hvrand=13036557734812844423&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9029652&hvtargid=pla-390433710667&psc=1

This one is on amazon but same stuff

Nice find on the pulleys, Jim. I’ve used the waxed thread Devon is talking about. Used for the pull rope for the spout on the water tank I built a couple years ago for the Challenge. Works great but it does have a certain stiffness to it due to the wax.

OK, I found some 10 pound hemp string that seems to be working. Here’s the pulleys (almost done, still a place to tie down the “rope” end where paint and glue are drying):

And here’s a closeup of the bottom pulley:

And the pulleys kind of sort of almost work if you fiddle with it. This could allow me to pose it hoisting something…

And the roof is done (maybe a bit of touchup and a clear coat but nothing else):

And from the top so you can see the “metal” roofing better:

So I’m 99.5% done! Yay!

Very nice Jim

Since you have some time to play … Try getting your hemp string wet and dry it with a hair dryer. Hopefully it will shrink just enough to tauten the look. Use heat to shrink and air to finish…

Ready set go!

John Caughey said:

Try getting your hemp string wet and dry it with a hair dryer.

Won’t that make it Thai stick ?

This post has been edited by: Rooster