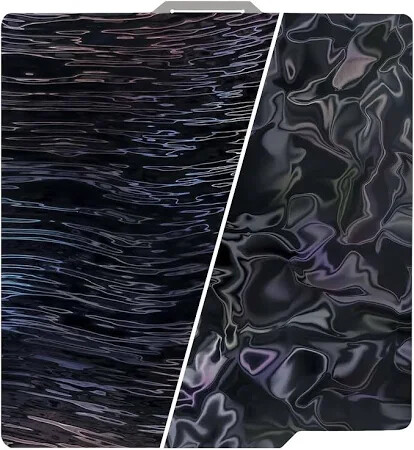

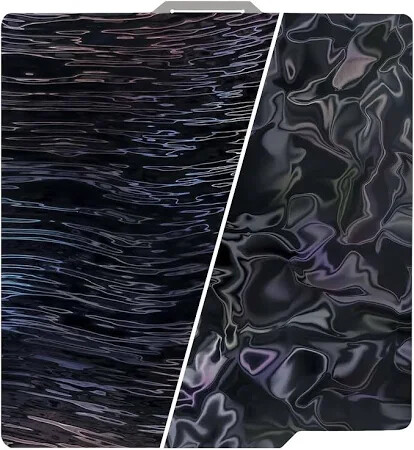

In addition to wood filaments (not what I will be using), I do have a “wood grained” build plate that I will be using for my build. You would also want to use one.

This video on using wood grain filament also does a good job of showing what my X1C can do. This material may be desirable to use for an indoor set-up, but the PLA would not stand up to UV.

https://youtu.be/NK7JzLaM0iU

Here is a wood grained/surface water build plate like I have. You would want the surface to be textured so it would be face down. But, the raised “fish plates” would to screw you over.

If the ties print face down, the body of the tie would not lie on the plate so would need supports requiring more material that would have to be removed. If they printed face up, a solid bottom would take on the pattern, but you wouldn’t see it and that wastes a lot of material. If you printed them like AristoCraft ties (i.e., vertical sides with flat top) with the fish plates up, the sides would be fine, but the top may require support, again more material to use and remove.

My suggestion…, print the ties as two parts. Leave an open square in the “wood” for the fish plate and print the tie like an AristoCraft tie with the top down on the plate for texture.

Then the fish plates that hold the track would be printed as a single piece and mounted from underneath with the “plates” coming up through the squares to hold the track. These could even be with a smooth texture, rather than wood grain, like metal would be, and could also be in a different color regardless of the printer.

Seems like it would take a long time to make a whole lot of ties, though you could do a bunch at a time and because they would lay in different spots on the plate, their surface texture would vary with the plate.

)

) I 'd rather replace all the ties early than wait and have ongoing maintenance…

I 'd rather replace all the ties early than wait and have ongoing maintenance…