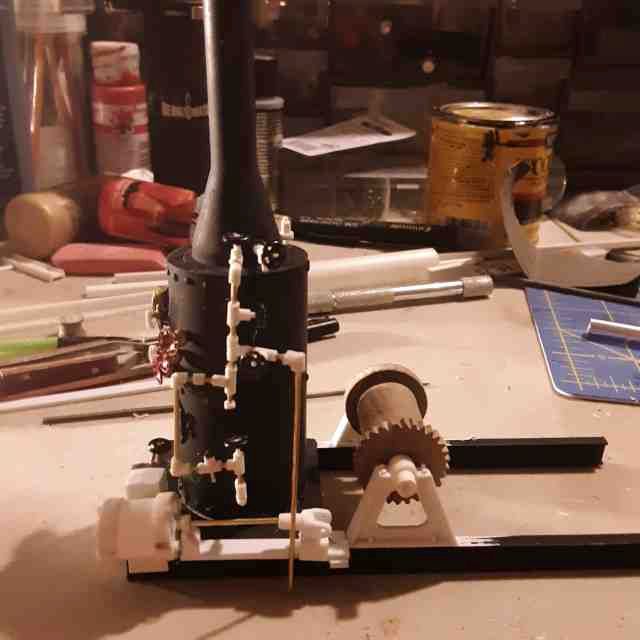

I was just sitting here pondering my ambitions, when I should be working. I really want/wanted to build this crane. But I am having so much fun detailing this engine build all on its own. A compromise might have to/must be made. Do you forgo the detail and get the bigger crane done on time or do you take what comes and do the detail work you are enjoying doing. In order to get the level of detail I am wanting it must be done before it gets installed in the crane. As this will be a mostly open sided crane (precisely so you CAN see the details) details are important to the over all presentation. This whole work train is meant to be more of a show piece than a ten foot rule piece. So with that said:

-

Rule #1 must apply at all times. Detail work is fun.

-

The “Spirit of MIK” is to build something from what is in the parts bin during the slow winter months and enjoy doing it.

-

The “Spirit of Devon” is to not stress out about anything right now.

-

I will be happier with a detailed model from bits and pieces pulled out of a zip lock bag than I will with a model completed in 30 days.

-

The “winners” of this challenge are those who are participating, whether or not they are building or spectating, not the one with the best model built on time. I have never cared one hoot about “winning” because I already won as soon as I started sharing my build with others and have joined in others as they build.

So the decision has been made to say “damn the torpedoes (in this case the time constraint)” and build this thing the way I want to build it on my time frame. If it so happens to get done on time, fine. If not I hope you all stay tuned and give me props and continue to make me feel good about myself with all the kind words. And most importantly continue on this journey on the anatomy and inner workings of a steam crane. Seems I am not the only one who is enjoying what I am learning along the way.