Next on the list was to make the friction drums. A lot smaller discussion. But it is the next part of this model that I made.

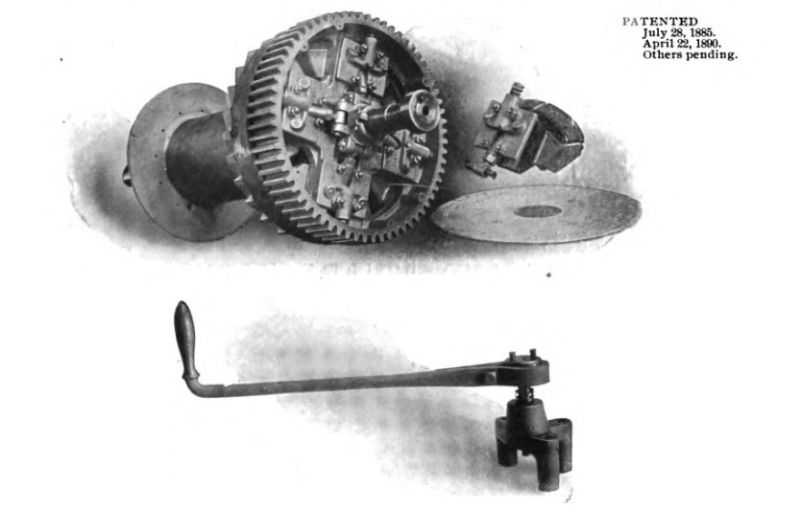

I first wondered why they were called “friction drums”; as I figured this had something to do with either how they were held in place under load or referred to how the cable was held onto them. Wrong on both counts. It refers to how they are driven and explains to me how two or more drums could be operated off the same engine at different times. It also explains why each drum has a handle (shown above) on the end of each drum shaft. So the big gear on the end of the drums is in contact with the smaller gear on the drive shaft which is connected to the steam cylinders via the connecting rod. When the drive shaft turns it then turns all of the gears on all of the drums but does not turn the drums themselves. The operator begins to crank on the handle which pushes friction blocks (in the case of the prototype are made from hardwood) outward from the shaft and comes in contact with the inner surface of the spinning gear. As it comes in contact friction grabs the spinning gear and begins to turn the drum. it can be a limited slip affair or clamped all the way down for positive grip giving the operator control over the drum. The top part of the picture shows the four friction block mechanisms surrounding the shaft and a small example of just one of those friction blocks. Pretty ingenious design. The saw blade thing to the inside of the gear is the brake ratchet thingamajig. As the drum spins a ratchet pawl clicks into place on each tooth. When the friction on the drum is removed the ratchet locks the drum in place. A brake handle releases the ratchet and allows it to be moved in the reverse direction again being held by friction to control it its drop. Or the engine itself can be reversed and drive the drums in reverse. Each drum is fitted with friction blocks and ratchet thingamajig for independent control over each of the separate drums.

In addition to the drums themselves many of these hoisting engines have additional capstan winches or gypsy style winches on the sides. These are what I was thinking when I thought “friction drum”. A rope is wrapped around them with the operator taking hold of the loose end. the rope is not wound around the drum as much as is just given a wrap on it and the loose end piles up at the operators feet. When the operator puts tension on the loose (tag) end of the rope it tightens the rope on windlass (drum) and friction bites the rope and begins to haul it in. Speed is governed by how much friction or thus how tight the rope is on the drum. This can be used when a permanent attachment of the rope is not desired but you need the pulling power of the steam engine. Now what I don’t understand is how this winch and the drum which appear to me to be on the same shaft can be operated separately. How does the winch spin and not move the cable on the drum. Considering it is the gear that is spinning all the time and not the shaft. Unless there are more than one shaft one attached to the gear and over to the winch and an outer one that is attached to the cable drum?

I did not get the ratchet thingamajigs on my drums. I will need to figure out a way to add them. Sure wish I would have noticed this earlier when I was turning them. Oh well I will find a way.