A barrel of tie plates would be too extravagant for the railroad that you describe…but you guys would know things like that, I’m sure. Had they even been invented, or in use back in the days you seem to be modeling in.

If they were in use, back then, it would only be on main line, major railroads.

Fred Mills

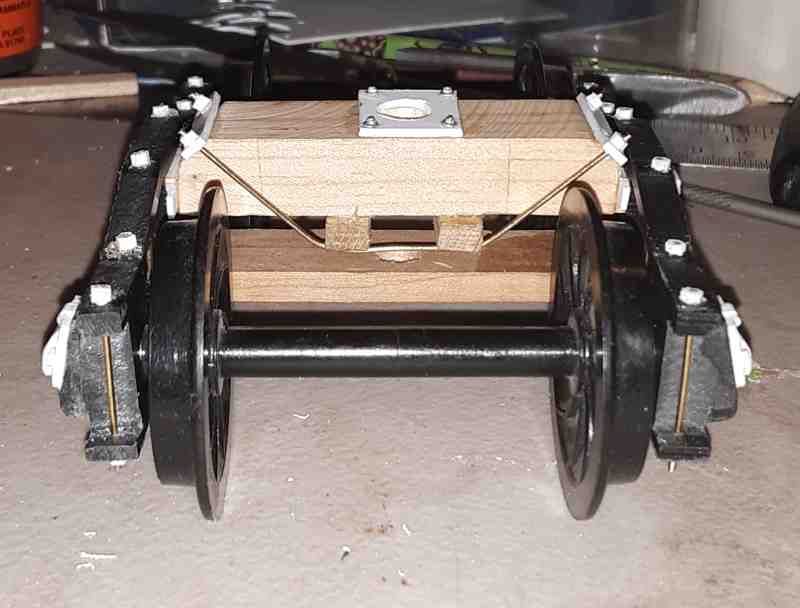

.jpg)