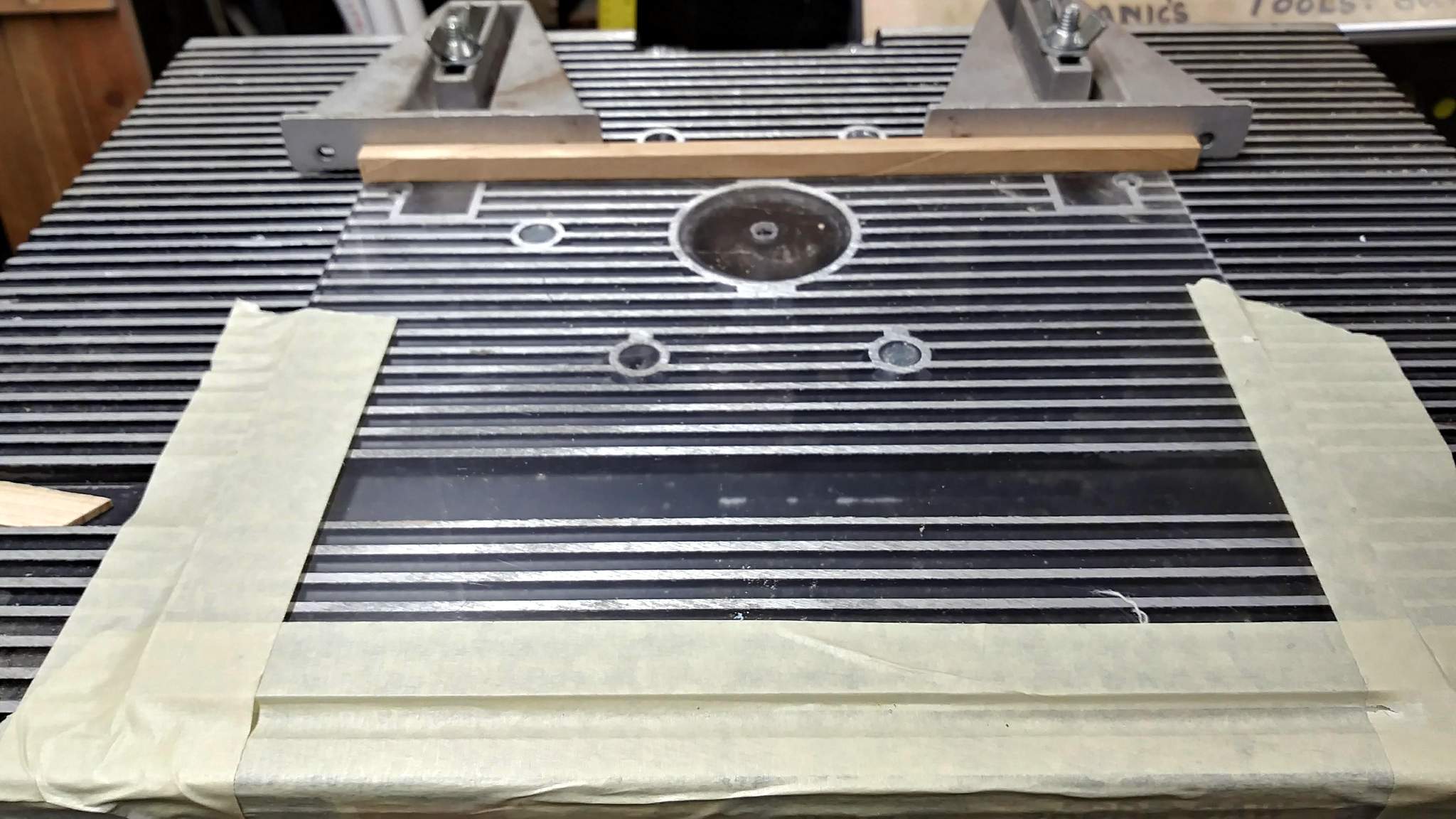

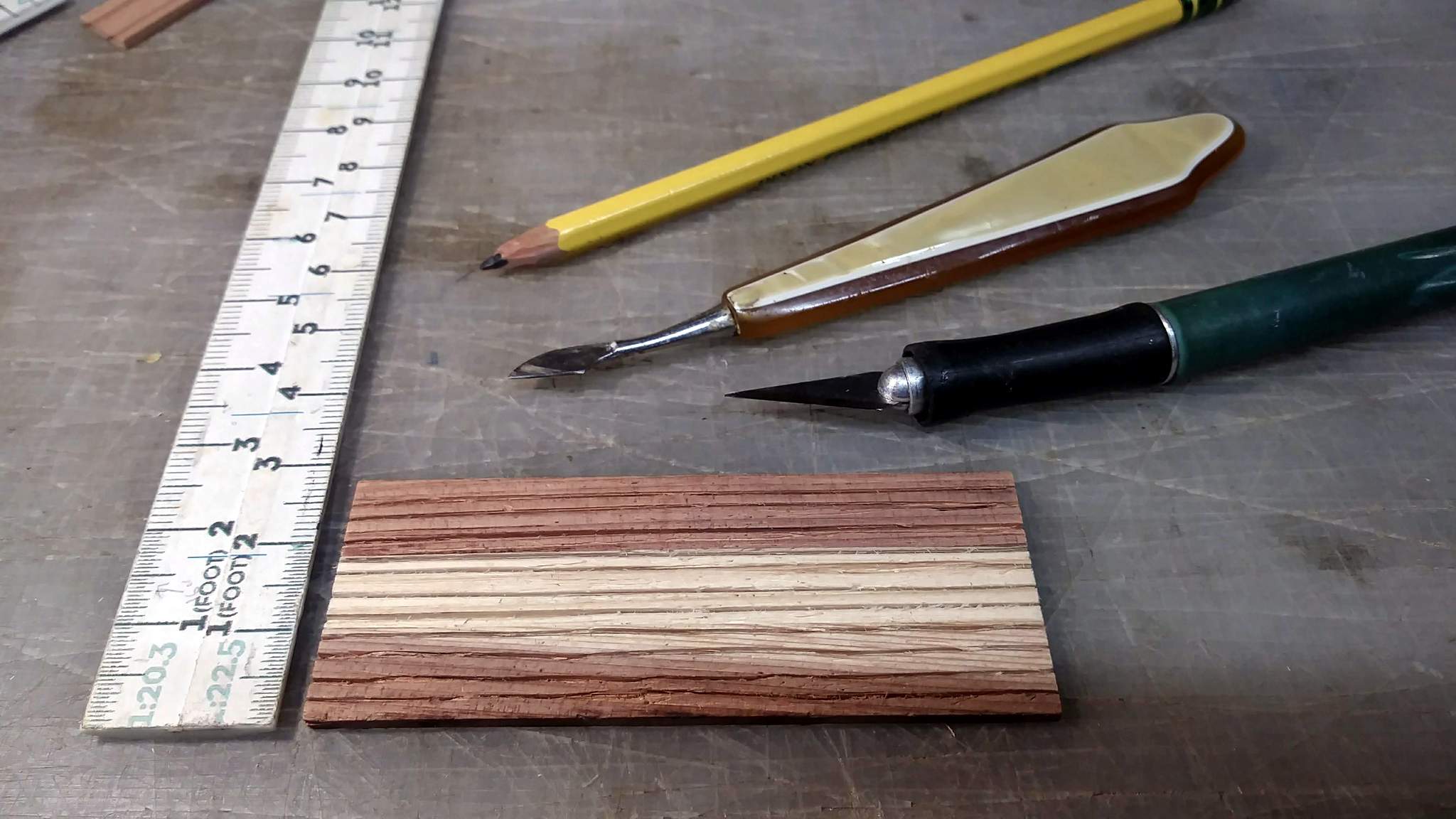

Got all but two of the battens done over the last few days and also attached the side walls to the rear wall and test fit on the base. So far, so good! I’m leaving the front off until I have the door finished and maybe the insulator detail done. Here is the latest photo dump…

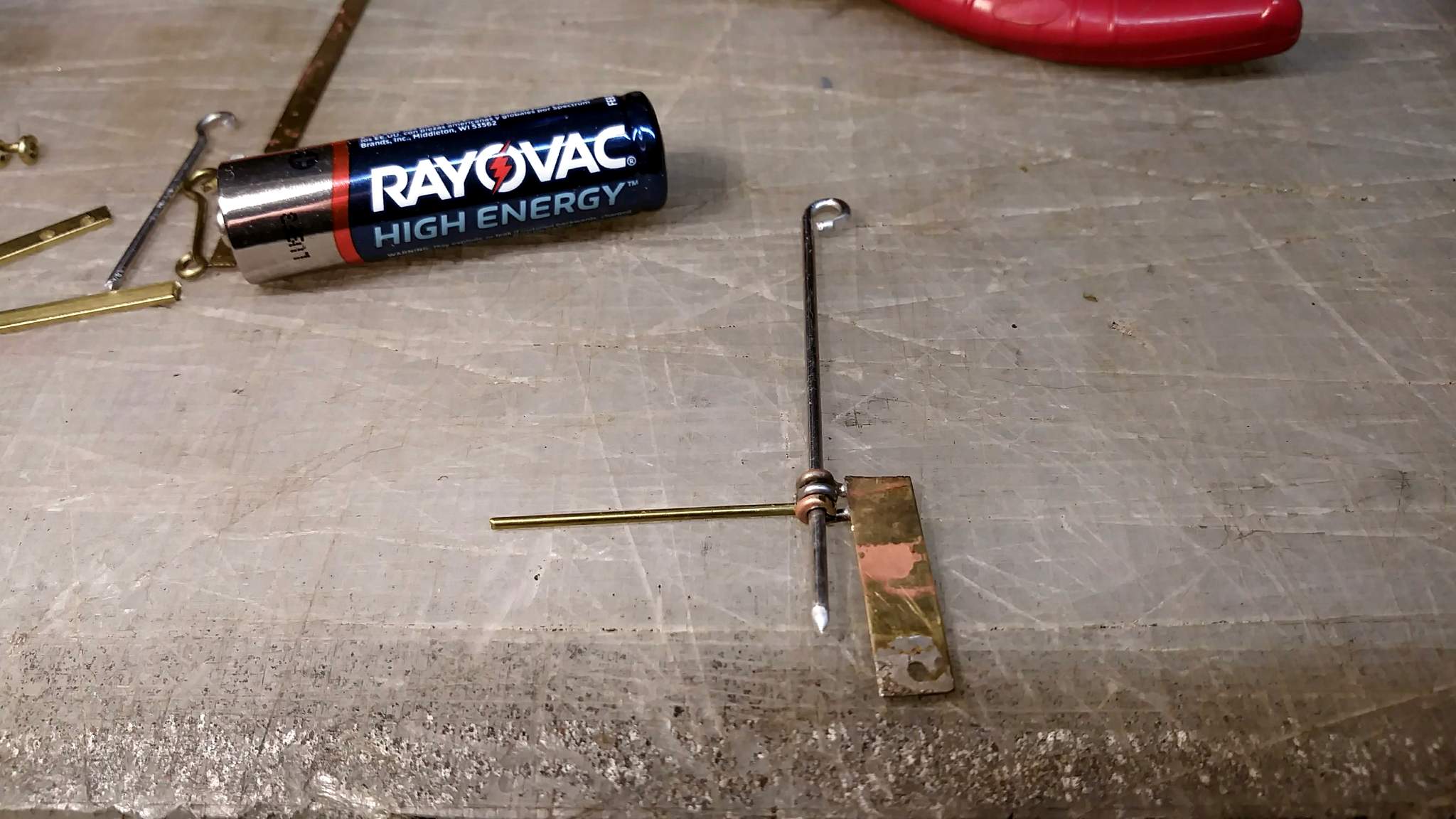

This weekend’s project is building and hanging the door. I want it to at least have the appearance that it operates. I’ve been browsing how to fabricate hinges, but since the door opens in, they won’t be visible so will probably just be some brass stock bent to the open angle and glued on.

I’ve also been watching a few videos on cracked / weathered paint techniques. I know Ray has done similar, and maybe Craig too. The method I found involves painting on wood glue and then painting over as soon as the glue is tacky. Washes then give it depth.