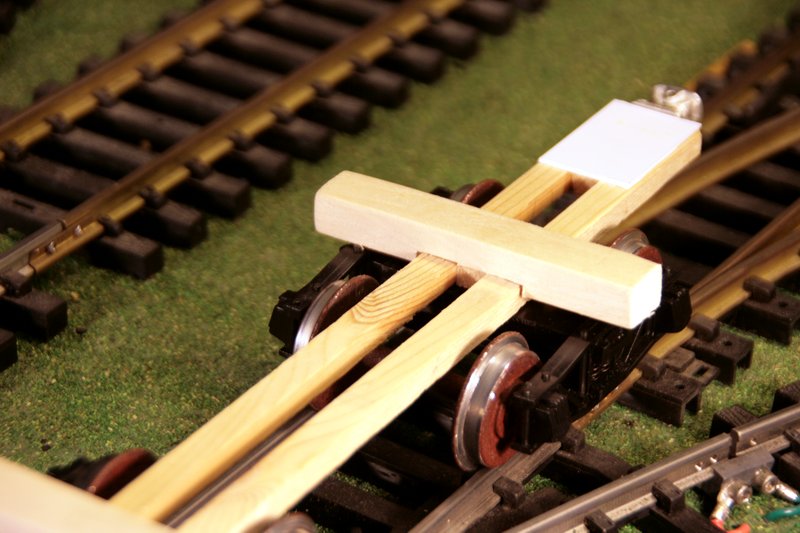

I decided to test Dave’s idea of just using the table saw to mill out the bunks so they will sit down over the sills, rather than on top. I need to measure more carefully for the production run, but for a proof-of concept it worked great! I also decided to widen the space between sills to be equal to the sill width. It’s a minor difference, but it looks much better to me. Here’s my proof-of concept frame out for a test run through some switches…

The white styrene represents a steel plate enclosing the draft gear that isn’t there and covering the sill spacer. It will end up painted black. If this car looks out of square, that’s because it is. The sills are seconds from the mill. They have have large knots that cause bends. I think I captured the low-slung look of Cale’s pictures…

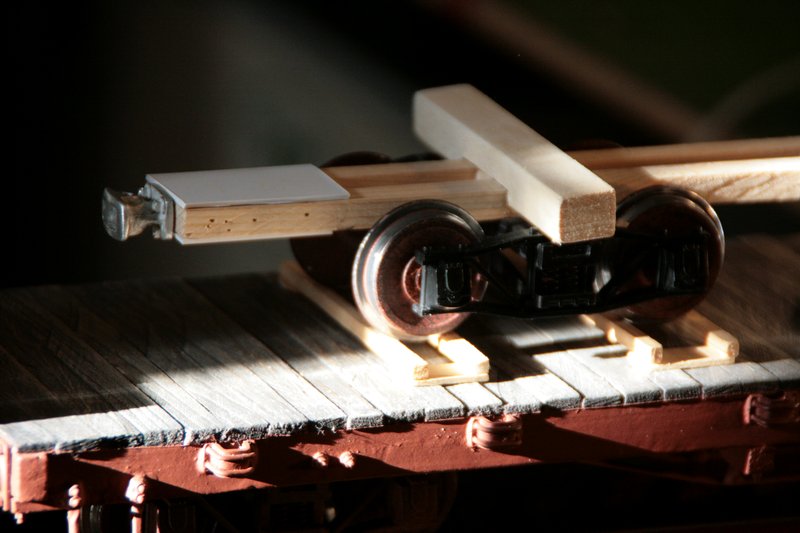

This last one is included because the lighting was so interesting…

Time to re-work the glue-up jig and get to work mass producing frames.