Management of the Candlewood Valley Scenic Railway decided that they needed some log cars to pull behind the 2 Cylinder Shay in order to more accurately represent how the Shay would have been used. Since it is nearly impossible to source wooden cars that are in operable condition, the CVSRy shops have been commissioned to build replica cars. The cars will not be an exact replica of any particular car, but rather a composite of the best features of several prototypes with specific design considerations to optimize operational capability on the CVSRy. Some of the photos and plans from a preliminary discussion are duplicated here. The log cars currently on display at the Cradle of Forestry are the inspiration for this project. Photos by Cale Nelson…

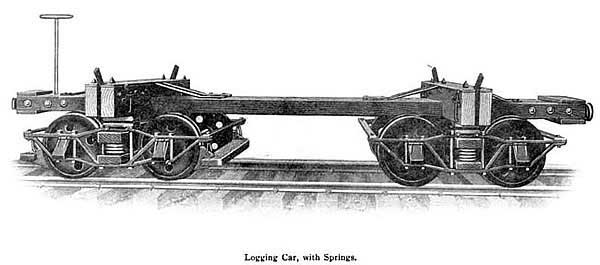

The construction plan will be derived from the Pacific Car & Foundry drawing provided by Mik…

The CVSRy shops will not be replicating brake detail shown in the above plan - these will be Operations Quality cars when done. Another prototype photo provided by Mik…

Before construction plans can be developed by the CVSRy’s Over Engineering Department, some tests needed to be performed. Because the design chosen places the sills below the tops of the wheels, clearances needed to be checked. A mock-up test car was built from composite materials for test purposes. First, trucks needed to be sourced. The CVSRy’s choice for Arch Bar trucks are the Aristo Delton Classic trucks. I remove the coupler tang for use on cars with body mounted couplers. For the log car build it was decided to also cut away the bolster pad to allow the sills to sit as low as possible giving the low-slung look of the Cradle of Forestry cars. Step one is to disassemble the trucks. Spread the side frames to allow an axle end to drop out of the journal box, then twist the side frame 90 degrees to allow them to be removed - don’t loose the springs !

A razor saw was used to remove the coupler tang and the bolster pad…

The coupler tang is retained for future use. It can be used to body mount Aristo/Delton couplers. The modified truck is then re-assembled…

Here is a comparison shot of a modified truck on the left and a stock truck on the right…

Next a bushing needs to be made to allow the truck to be mounted directly to a car with a 6-32 screw. I found that the tapered end of a PaperMate stick pen is the perfect size. I just slice a few bushings of the end of the pen with a razor saw…

Then place the bushing in the truck…

Then a 6-32 machine screw will attach the truck. I use a T-Nut in wood frame cars, or drill and tap plastic for the screw (Thanks again Bruce for tap idea)…

Here the trucks have been attached to a mock-up of the sills made from a scrap of 13mm PVC board and the mock-up placed on a section of R1 track…

From above we can see that there is just enough clearance to get the mock-up car through an R1 curve…

CVSRy engineers have thus determined that a total sill width of 25mm or 20 inches in 1:20.3 will allow the trucks to negotiate all trackage on the CVSRy including the yards. Keeping the cars coupled in the yards will be a different challenge :D…

Now that a functional sill width has been determined, the CVSRy engineers can now finalize the build plans and place orders for the shops to begin milling limber for the project. Next up will be the final dimensioned build plan. Stay tuned.

) couplers. Clem only had enough for 4 cars, so that will be the initial build. I’ll assemble a few others less trucks and couplers to be completed at some future date.

) couplers. Clem only had enough for 4 cars, so that will be the initial build. I’ll assemble a few others less trucks and couplers to be completed at some future date.