Hi Rob:

Good to hear from you, sorry it took so long to post again, the cold really got bad and I had substantial pain in my teeth from sinus pressure. It finally began subsiding

Thursday night…

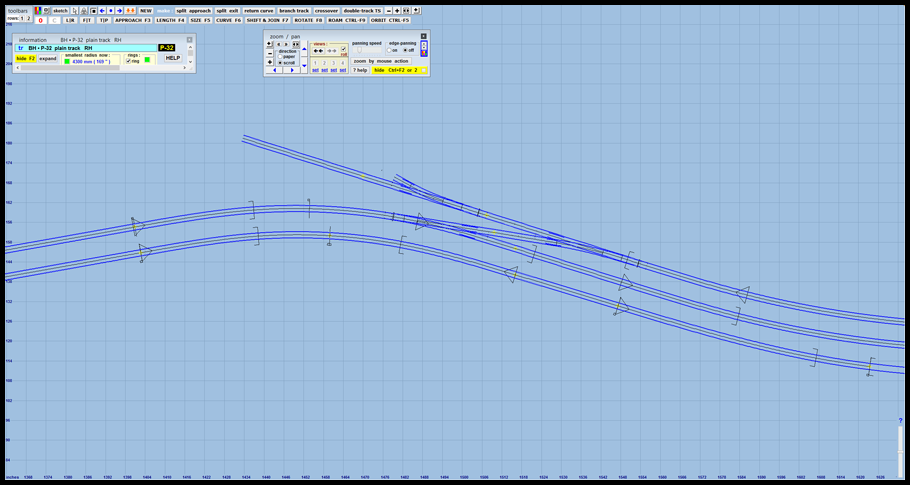

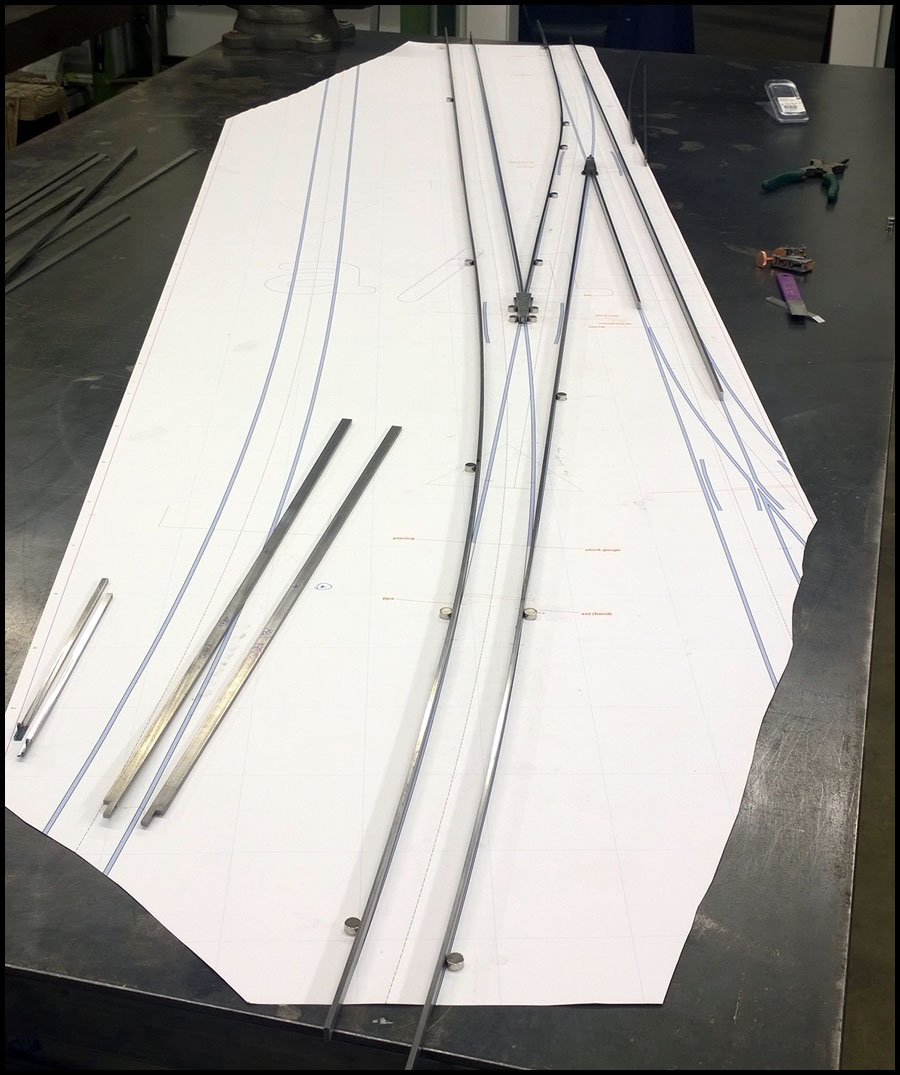

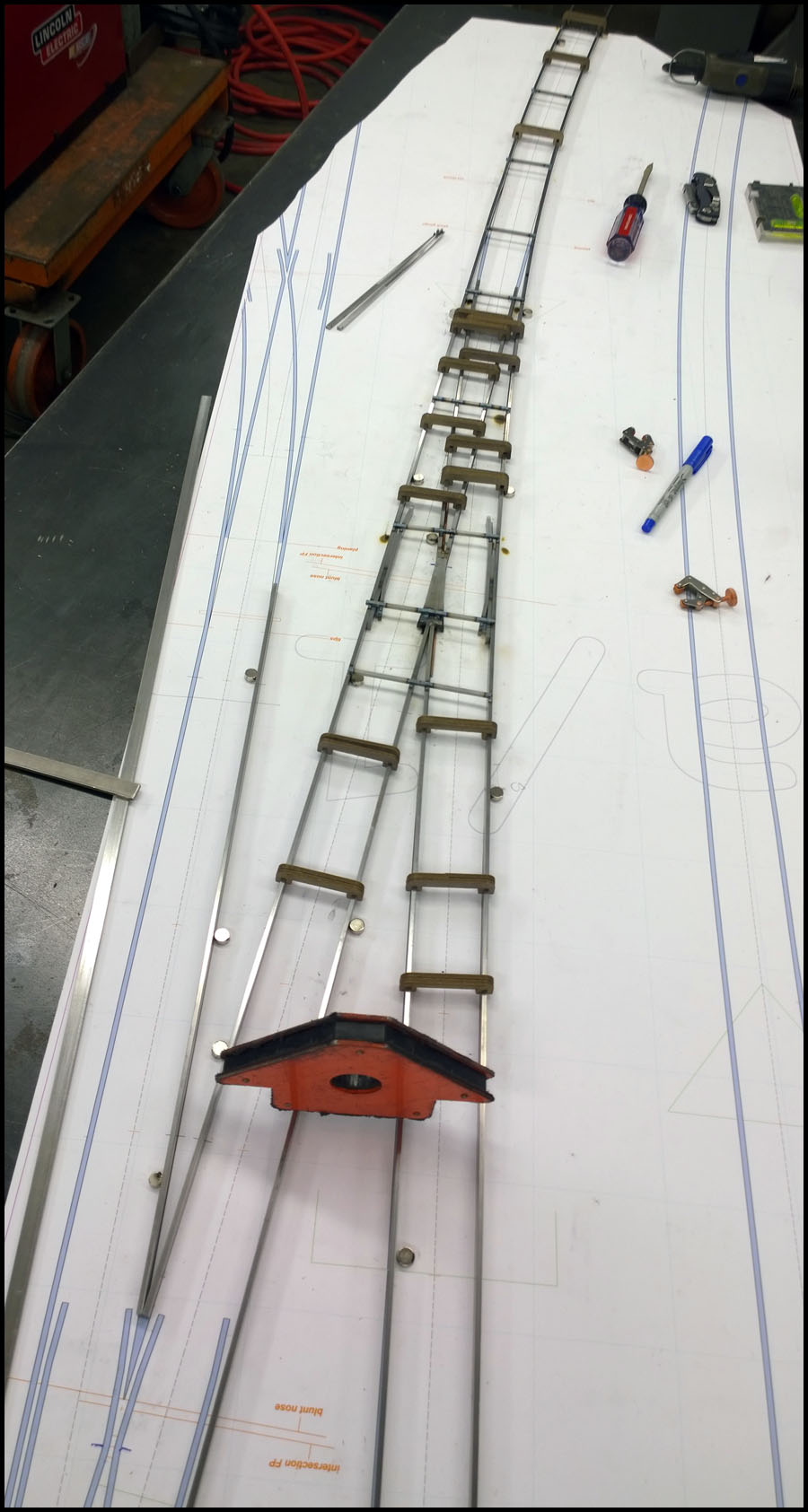

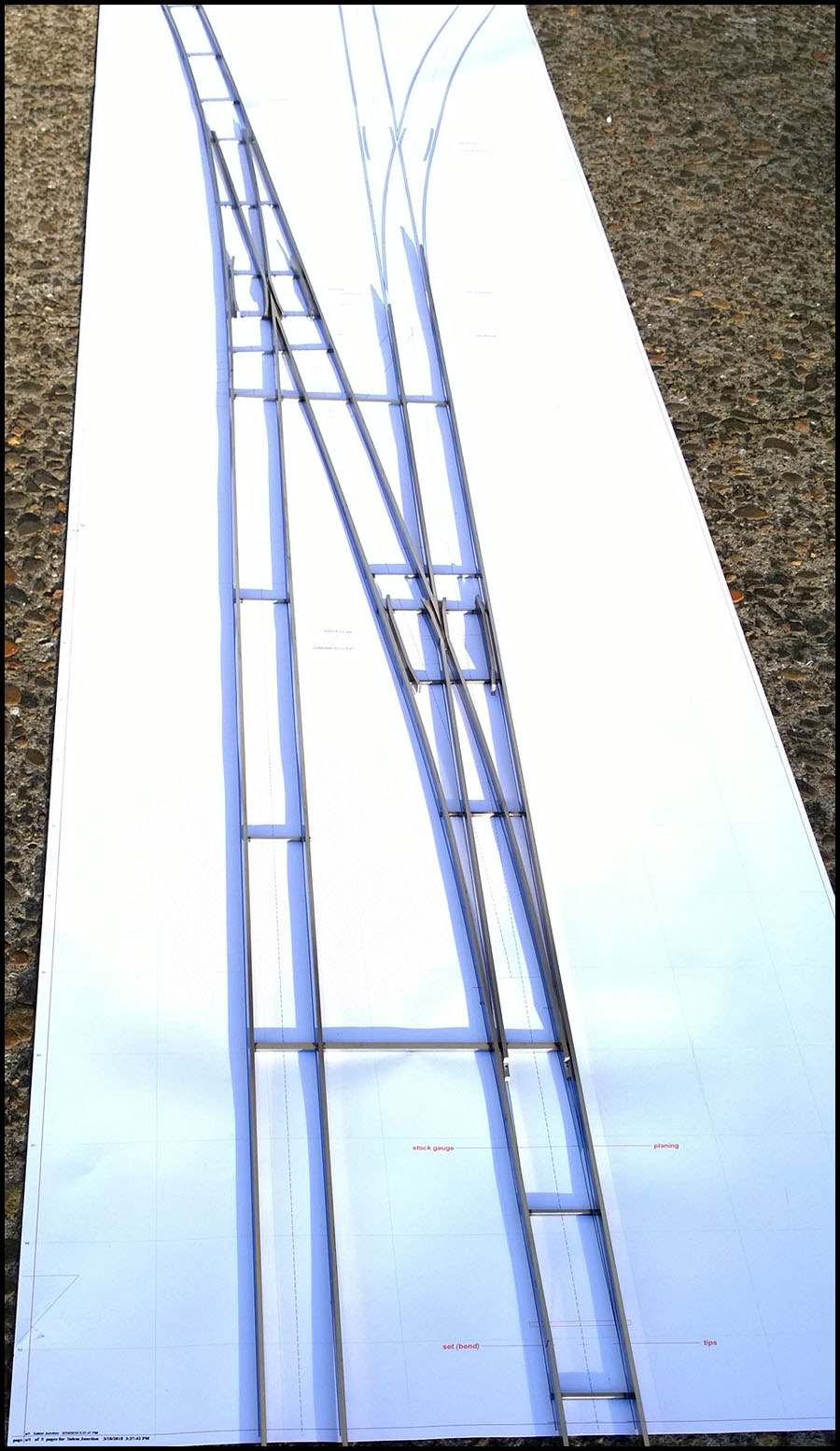

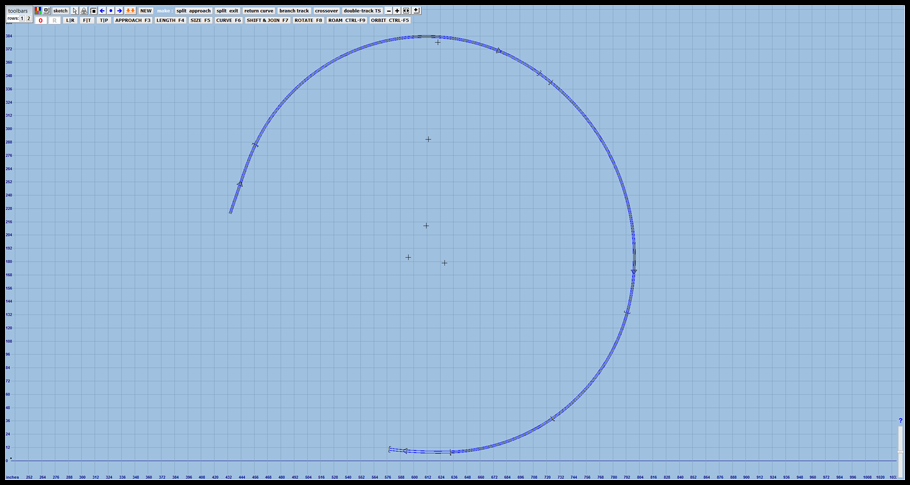

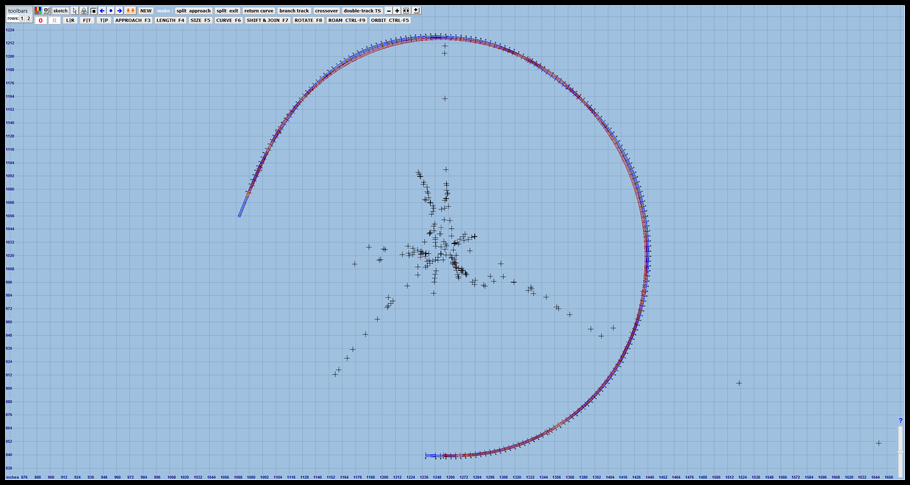

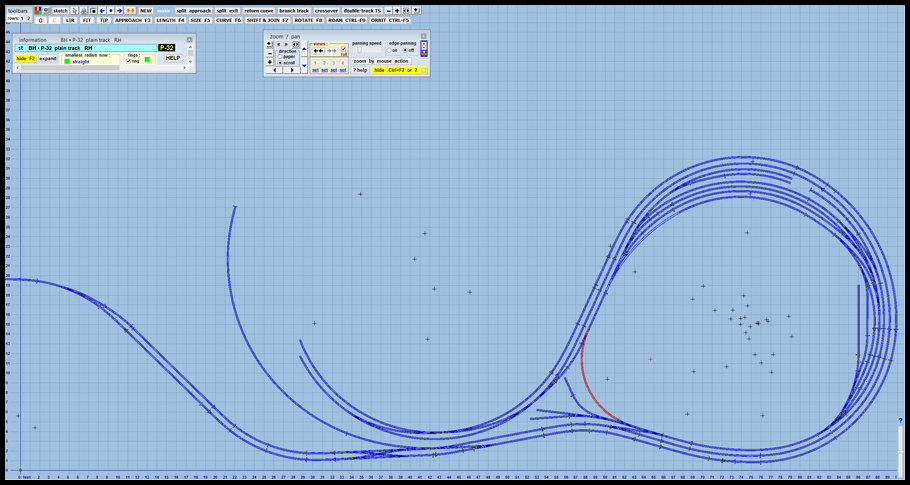

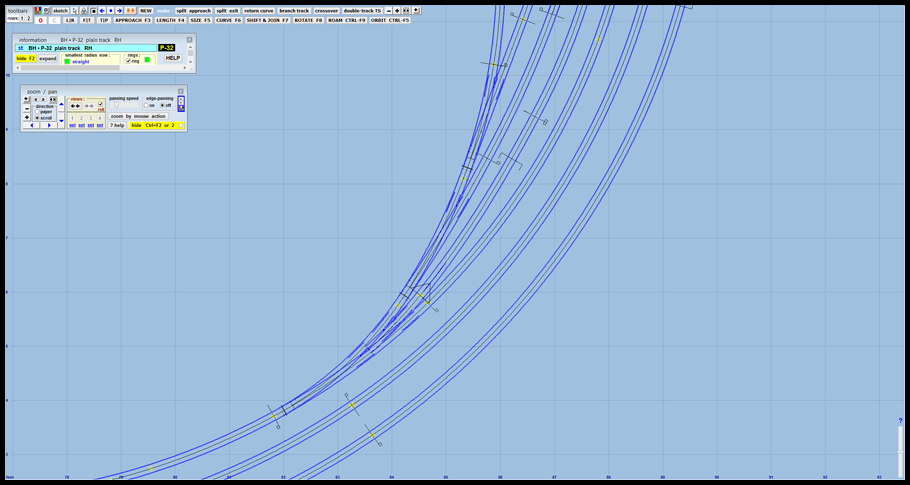

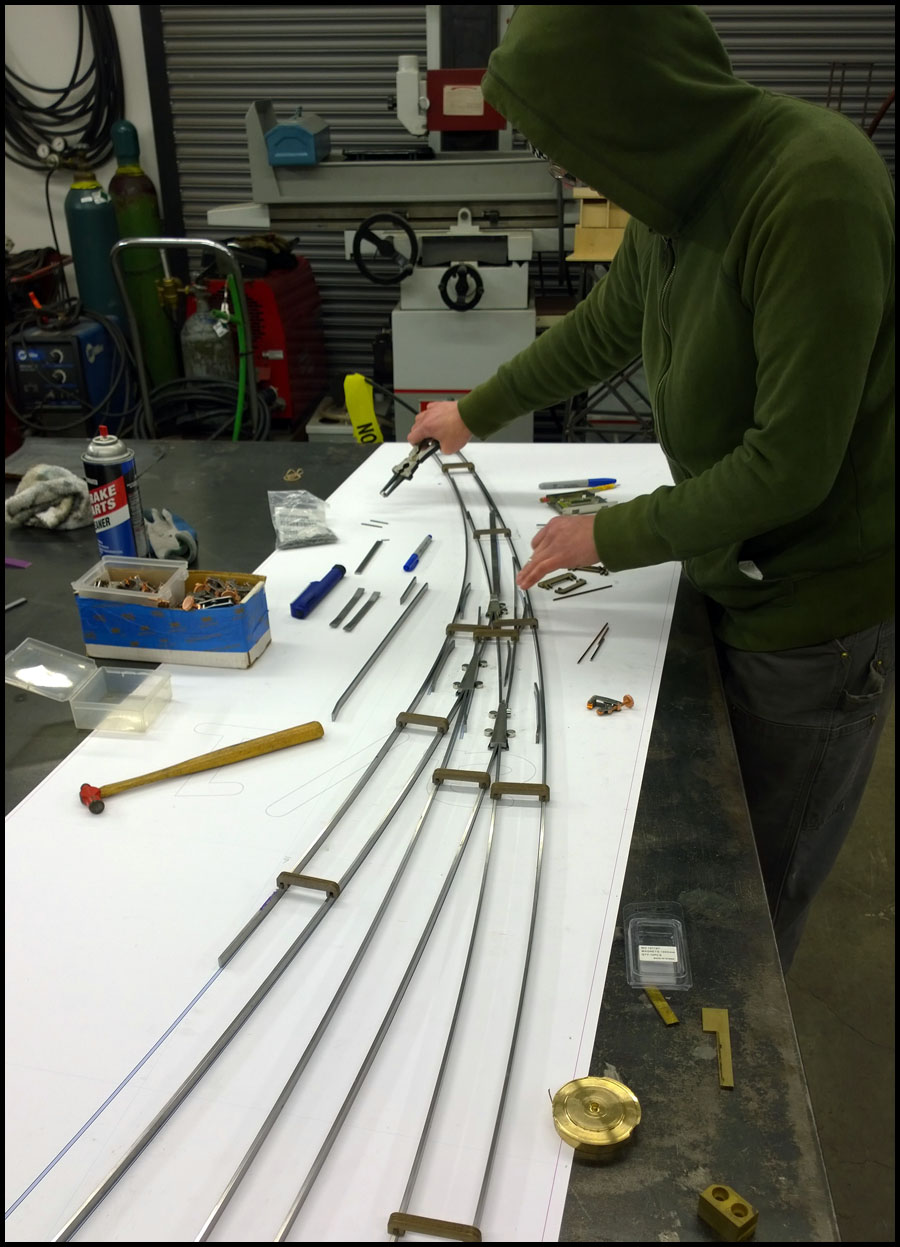

Also, the curved single sided tandem turnout we’re building this week was tougher than I thought it would be. Turned out great in the long run, but definitely had a

learning curve. We have to build one more, but now I know how so it should go much smoother.

The outdoor loop is remaining single track as plans are now, however, there will be extensive passing, staging, and storage tracks on the outdoor railroad extension. There is

also plenty of time for plans to change.

I appreciate the offer of the camera body, and that is a pretty nice camera from its era, but it is also about the same as the one I just had fail on me, after 12 years or so

it is time to upgrade. I have been saving my carburetor and distributor money for a while and have enough to get a nice semi pro or pro camera with lens package. My

problem is just time.

With April starting tomorrow, there is still a lot to do around the railroad. So my posts might get shorter or have a little less exposition.

This post will be to catch up on some pictures I’ve taken related to things in other posts. First is a report on the rust and corrosion preventative Fluid Film.

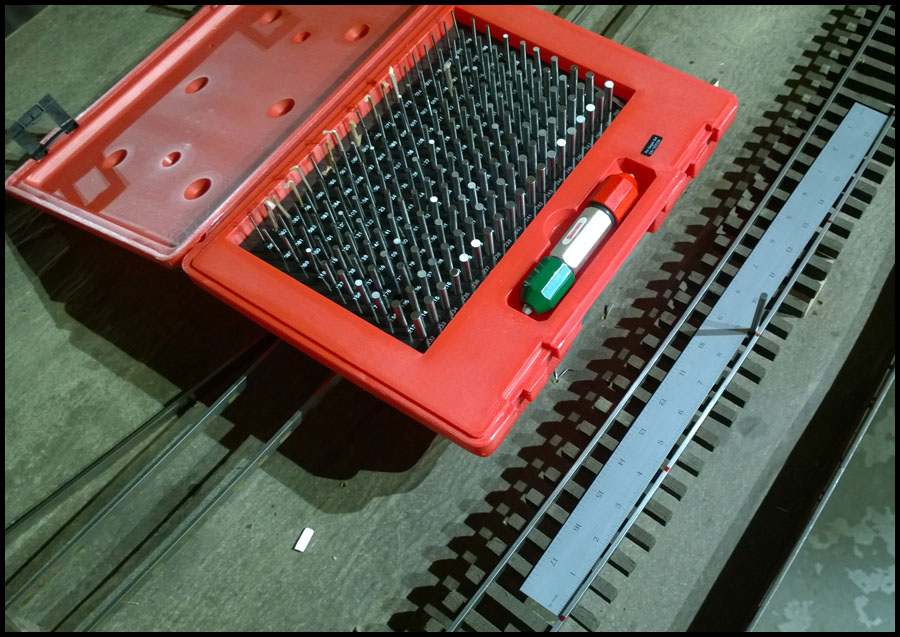

In the picture is the turnout with the Fluid Film sprayed on it twice during November. After sitting all winter, I walked up and it looked like some surface rust had

formed, but not too much. I figured a scouring pad would make it nice, however, I just wiped it with a rag, and it looked great.

I purchased this can to test the product. It is available in larger bottles and buckets that could be used to fill a spray car. You can clearly see in

the photo the difference in corrosion where it wasn’t applied.

Next is just a picture I forgot to post. Somewhere in all the last posts, are a couple about the diamond crossovers. In them, I mentioned

the angled pieces I make so that we can form the diamond. This is a closeup that clearly details how we use them.

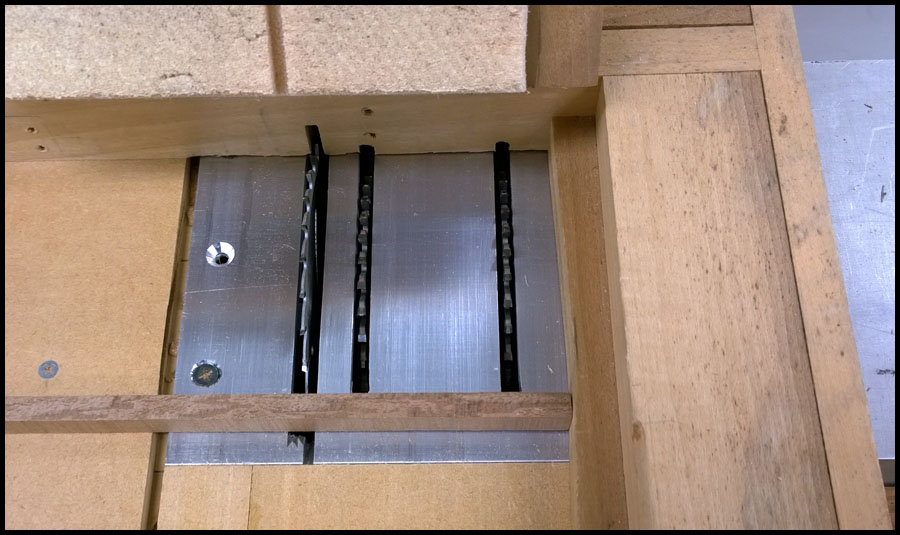

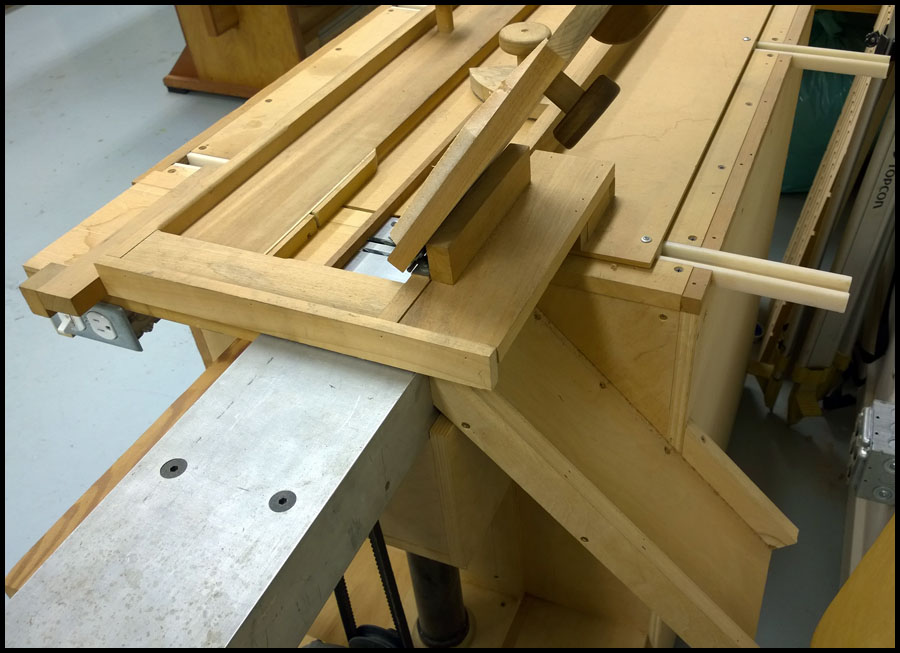

Next up are some pictures of the tie making machine. This cool contraption was built by a fellow named Jim who used to do a lot of the infrastructure

work on the railroad, and was instrumental in its original construction.

This is a picture of the spindle, which uses two 3mm(.118") blades to cut the slots. This gives a nice press fit on the rails. A sample strip of tie

stock is in the picture. In use many strips would be stacked and pushed through at the same time. The table rides in slides that can be seen

in another photo coming up.

It is hard to tell, but on the right side of the tray, a scallop is cut into the stop surface to the right of the blades. This scallop, allows the ties a

small amount of variability in length.

When the tray is pulled back away from the blades after a cut, you use the pusher to move a fresh stack of strips into position for a cut. Here

it is easier to see the scallop. Also, the tray would normally be full of much longer strips, but I didn’t have any ripped to length while taking

these photos.

From the rear of the machine you can see the exit chute that cut ties slide down into a bucket or box. You can also see the slides that allow

the table to freely move across the blades. A lid pushes down with foam to keep the tie strips in place during cutting. Something has gone

wrong with the spindle during the last use. The cut off blade is now wobbling around. I must remove the spindle and repair whatever is wrong

soon.

We must go work on the railroad some more. It is a sunny and warm day here in Portland, and I am feeling much better.

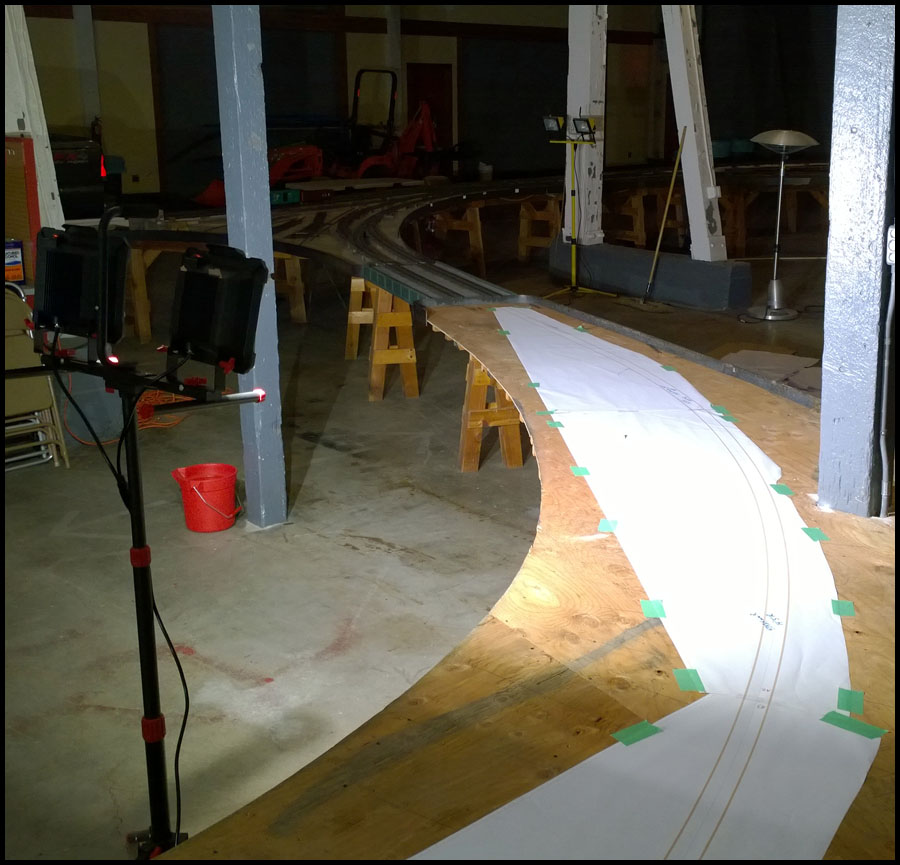

Next posts will be track work again. I have been editing photos to tell the story of how and why we tore out the middle loop and

are starting over, and how the new approach is paying off. I will try to post more often this week. Pictures are done…just need time.

Karl