Thanks for the comments everyone. Sorry I haven’t posted in a couple days, been feeling a little under the weather. Got a really mild cold, but enough to make me tired and achy.

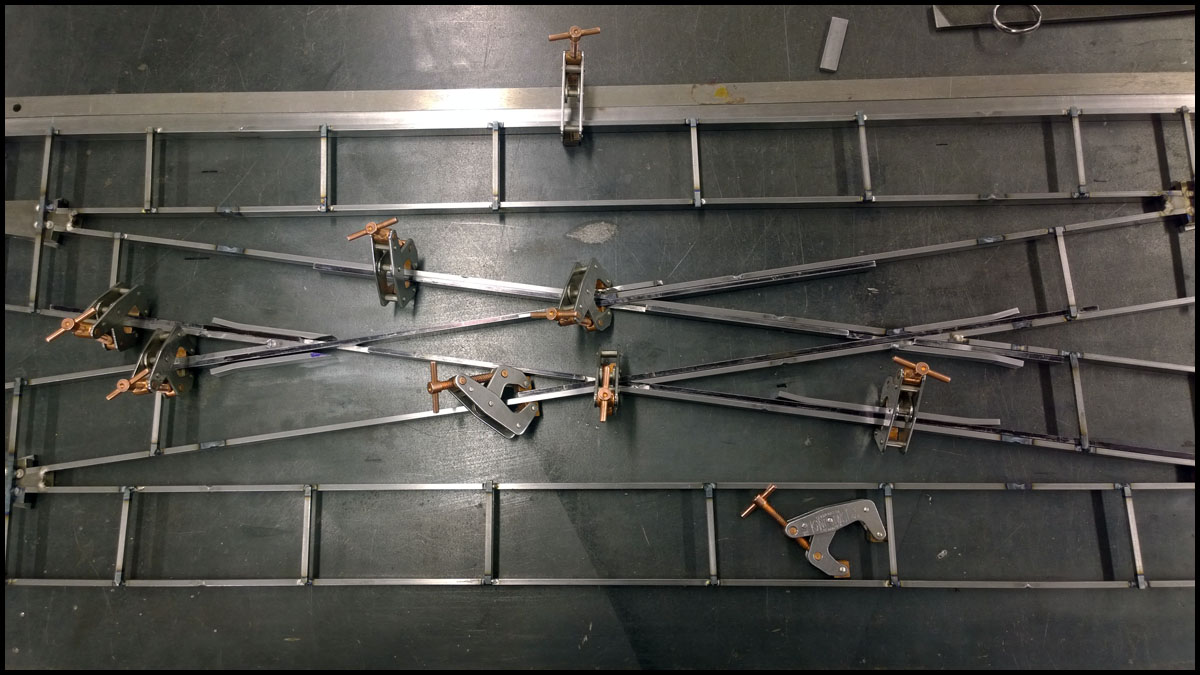

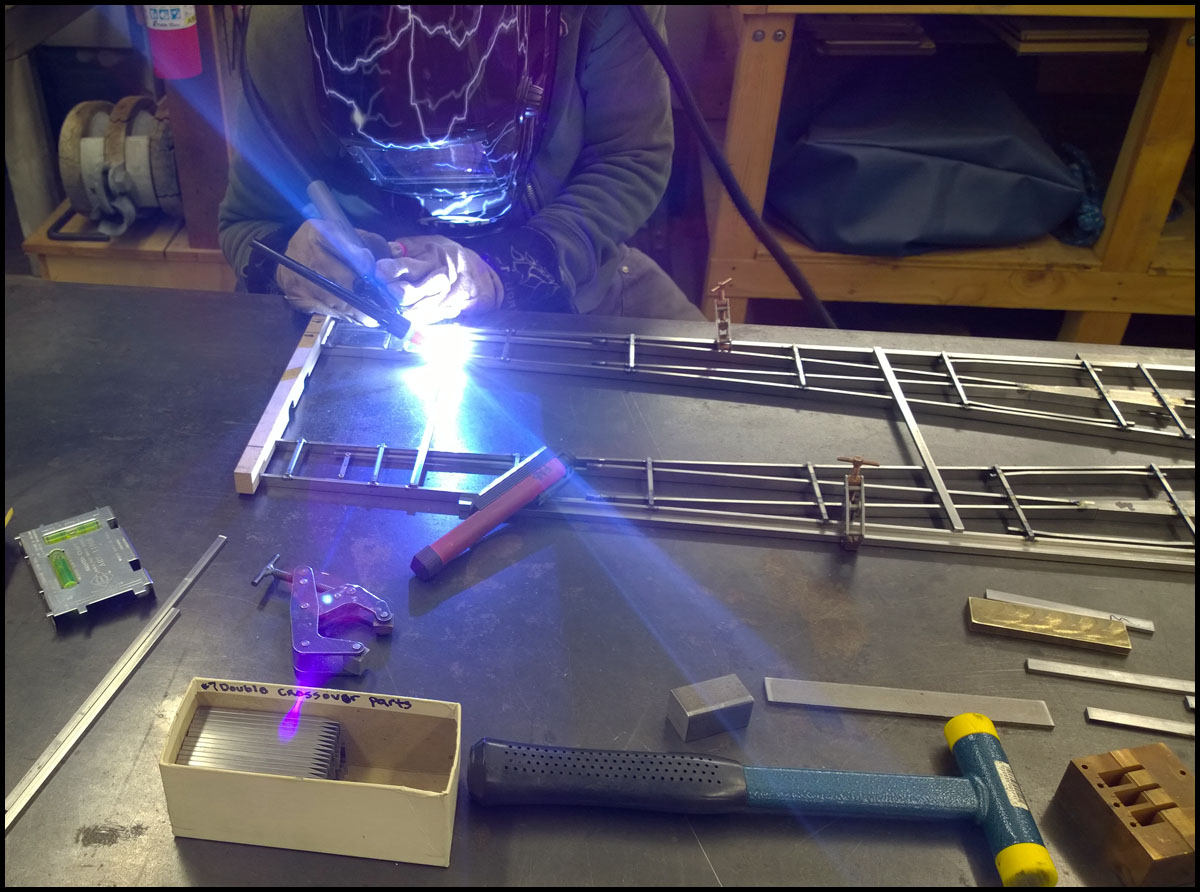

So here comes a few pictures of the #14 curved turnout Jenn and I built. I didn’t get many pictures because it actually went really smooth and before we knew it, the turnout was

basically finished. I took some pictures yesterday of the turnouts partially built for the yard throat that will show more detail of our methods. Until then, here is the curved turnout.

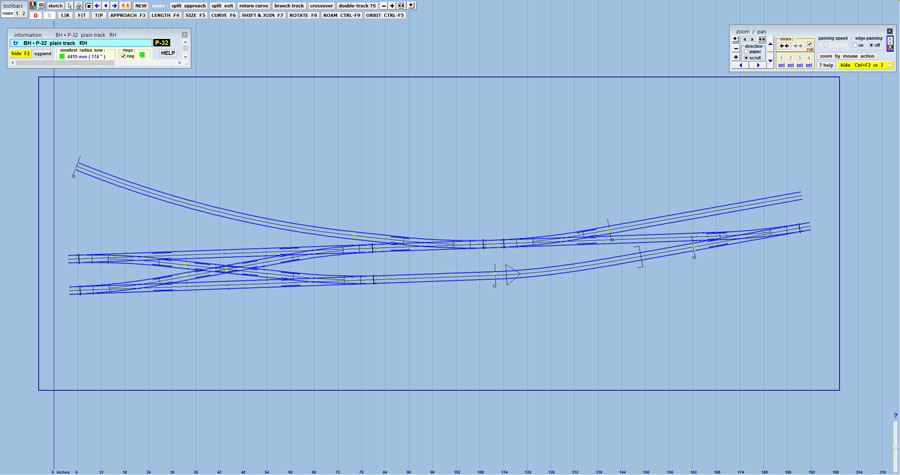

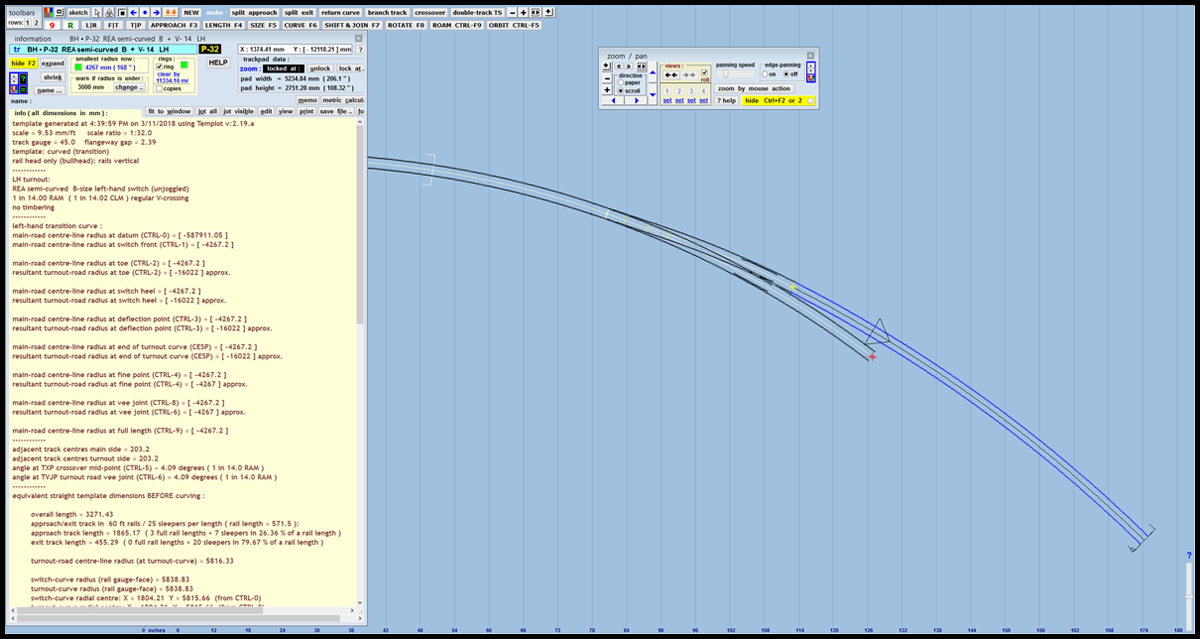

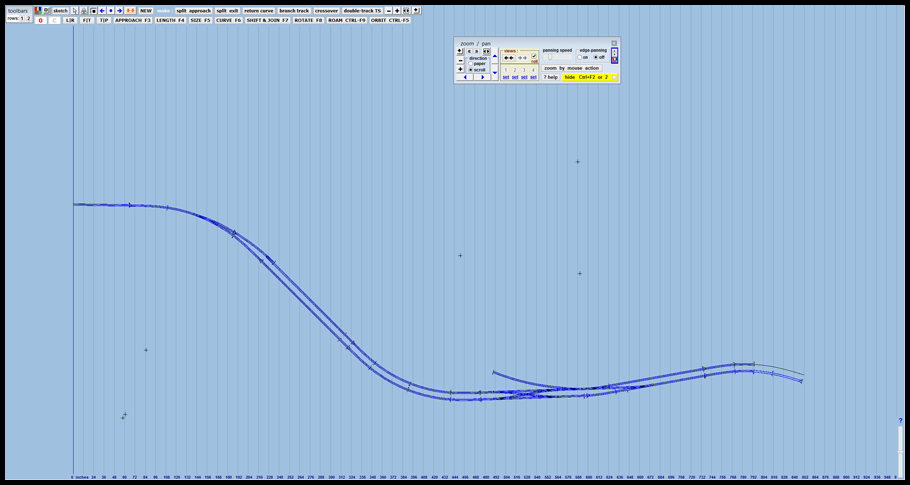

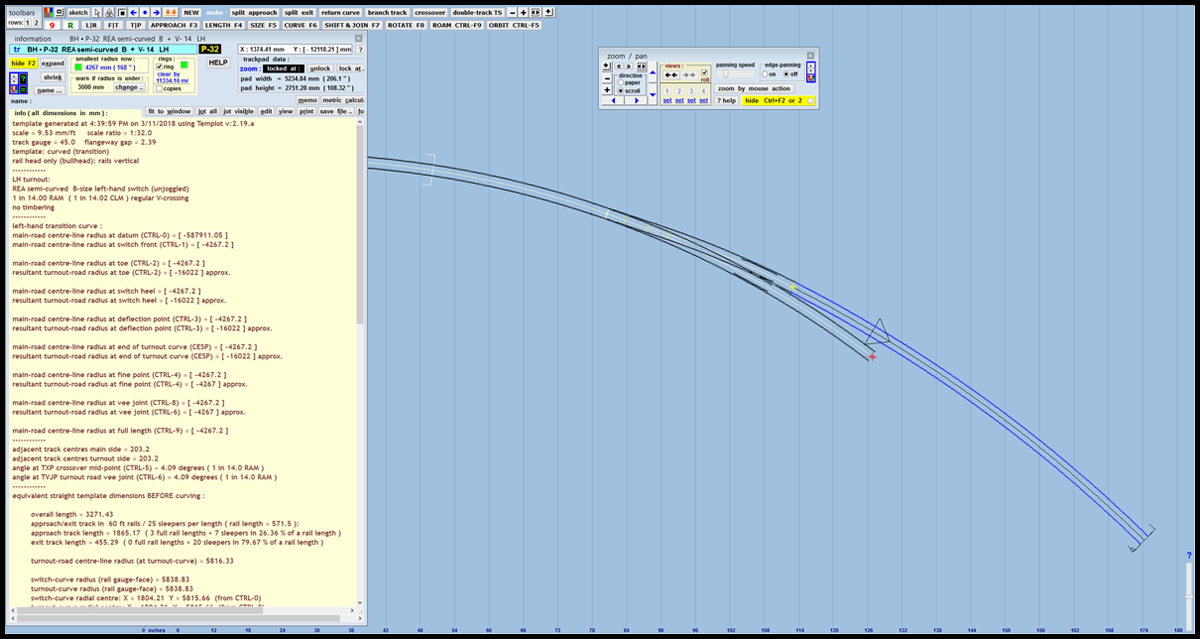

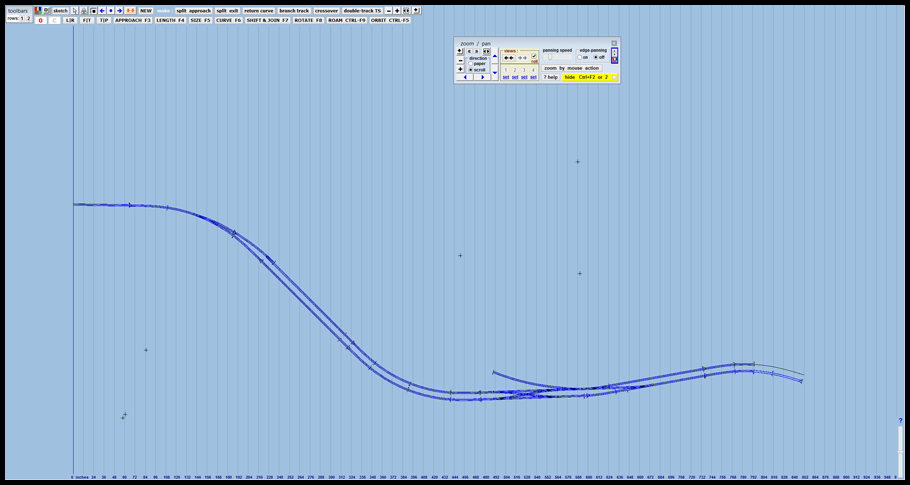

First, we start by creating the Templot template for the turnout. With the bridge installed to the outside track, we used long sections of steel, and a chalk line, to find the angle of

the curve. At the center point of the of the angle, I can measure to where we want to start the transition curve into the building. Once we know this distance, we can go to

Solidworks and generate a .dxf of the angle, import it into Templot, and then create the curves and the turnout and know that it will fit. We now have a few more tools to help

us perform these measurements more accurately. I will discuss these at a later time.

Here is a picture of the turnout generated in Templot. You can see in the open window on the left, more info than you can imagine on the characteristics of this section of track.

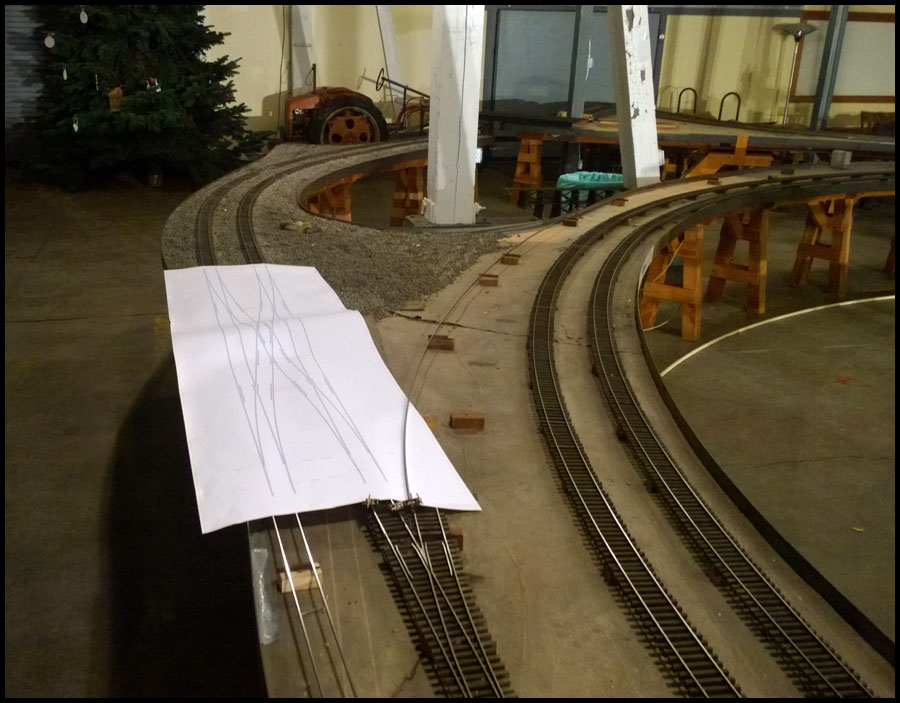

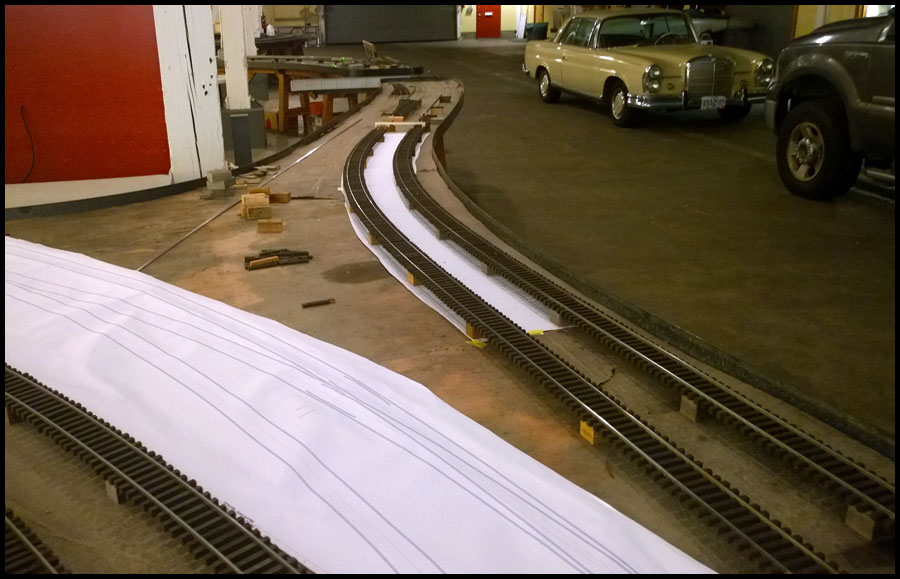

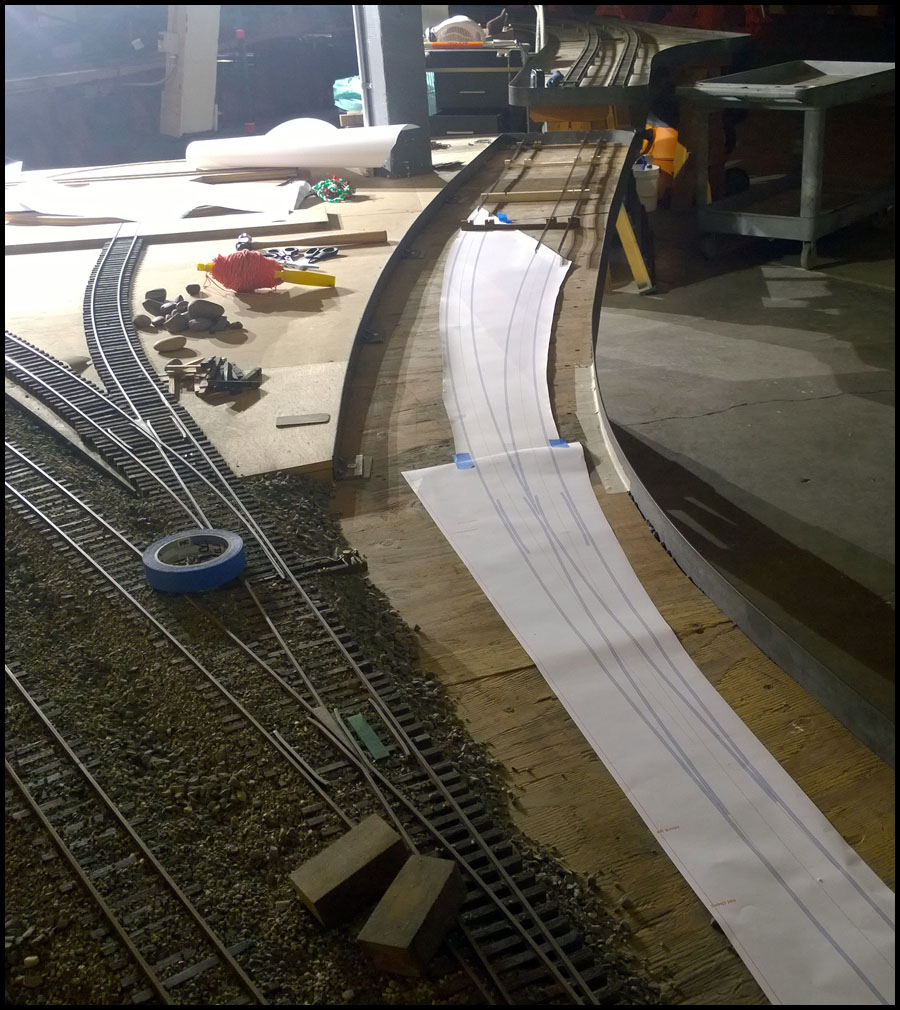

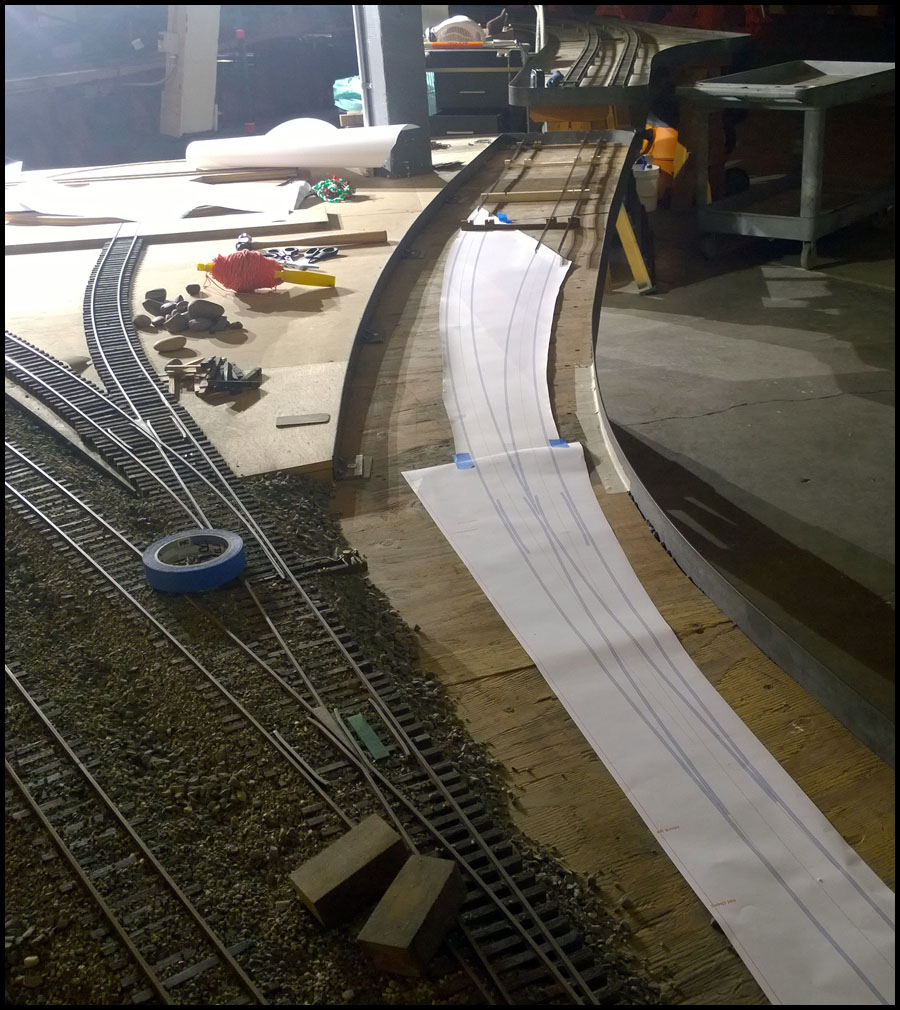

Taking a printout of the turnout and transition curves, I could lay out the entire curve, and use pieces of rail, and other things lying around to make sure of the alignment before we build anything.

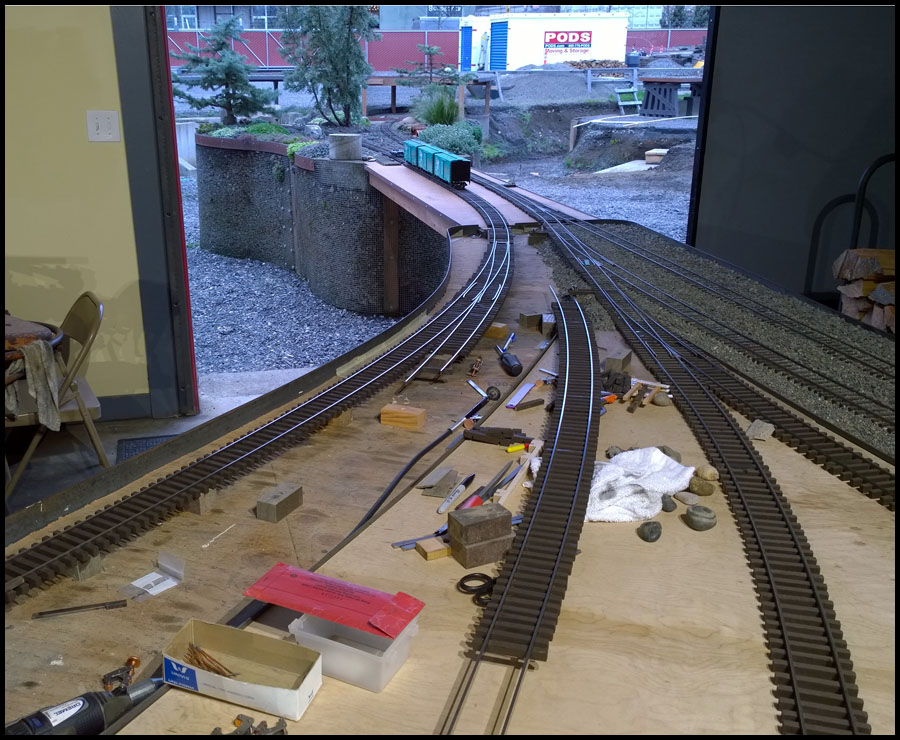

I didn’t think to get many pictures of the process. But here is a couple showing the turnout template in position and gives a rough idea how we go about the alignment. In this picture, you can

see the old curve on the other side of the bridge. This will get torn out shortly, but for now, we used it to help align the track work across the bridge.

Shot from the other direction.

I mentioned in a previous post that I wanted to modify the frogs we use. This next picture shows why…Many years ago, when they began making

turnout parts, a fixture was made for the manual mill that would allow frogs of any angle to be produced. As I have stated, most turnouts on

the railroad currently are #7, however, many #5’s, #8’s, #10’s, and #14’s were made as well. I now make them using a different method, but

we have a stash of the old ones still around and we want to use them. The problem is that they end up very long, which is fine for a straight exit, but

will not work well on a curved turnout.

It occurred to me that there was no real reason for them to be this long other than it is easy to attach rail to the design used. I suggested we cut the

frog back to where it is exactly a 1/4" wide, (the width of to rails butted together), re-cut the slots on the surface grinder so we can bend the guard rails, and then the curved

rails would work just fine.

Here is the result…

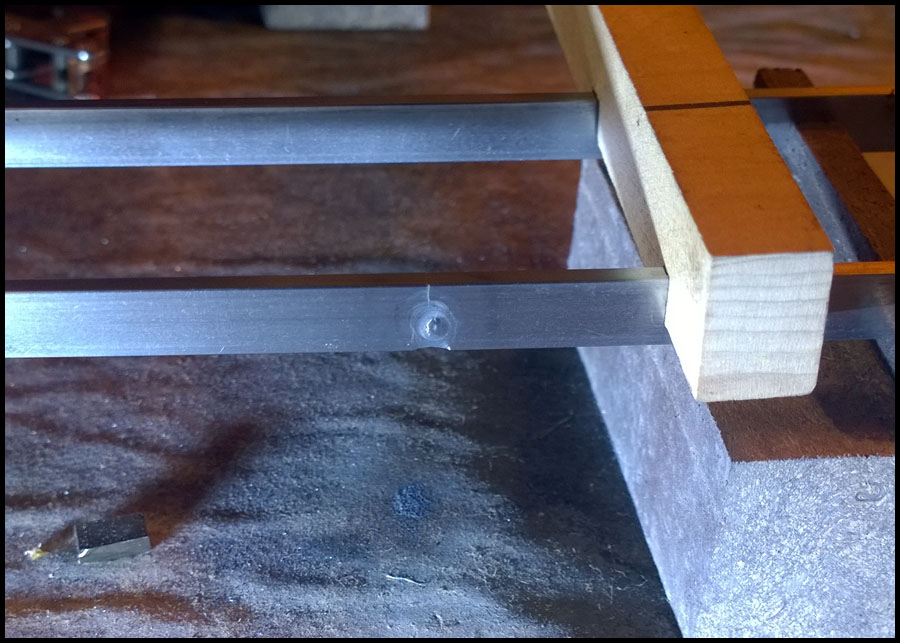

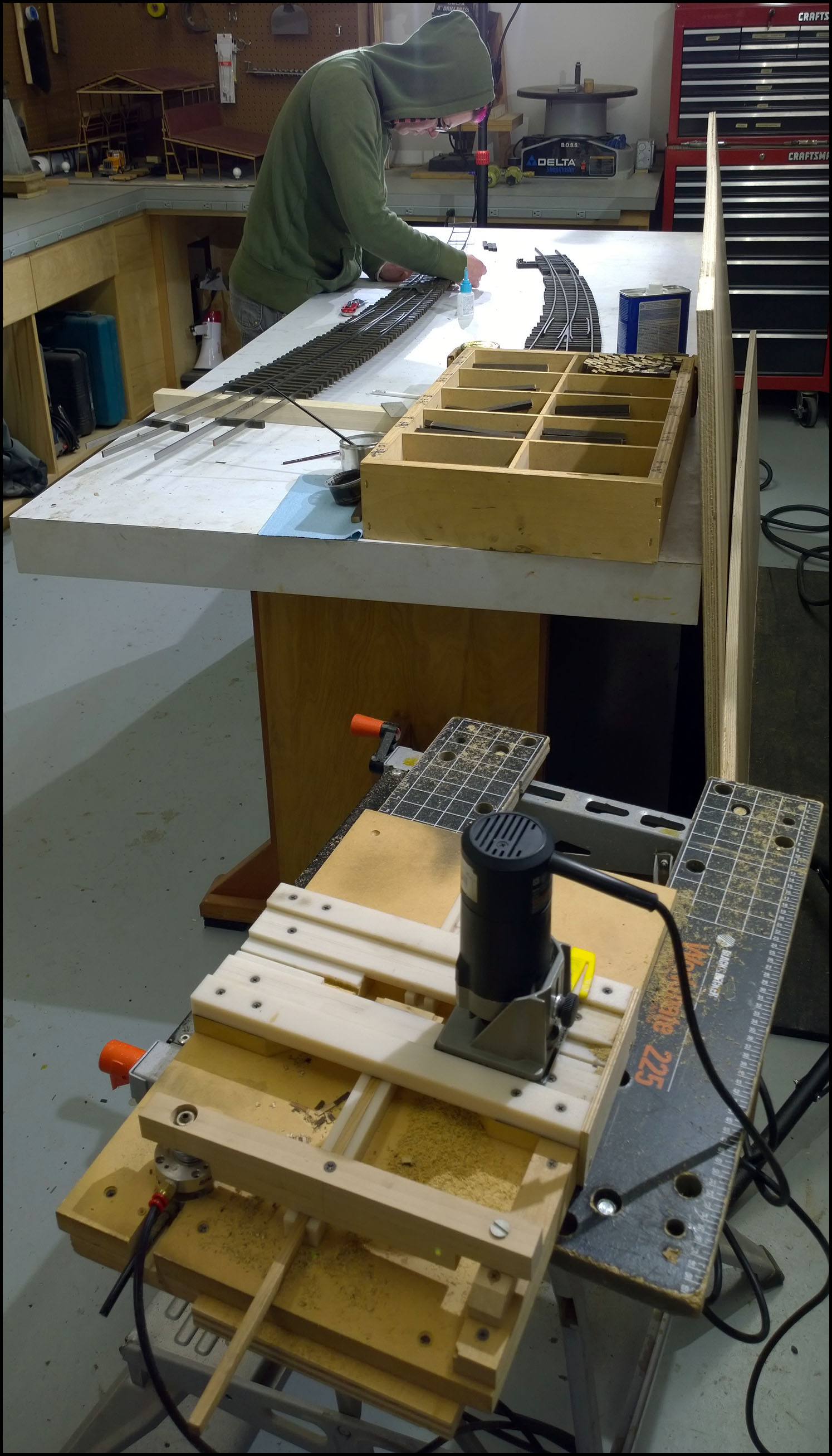

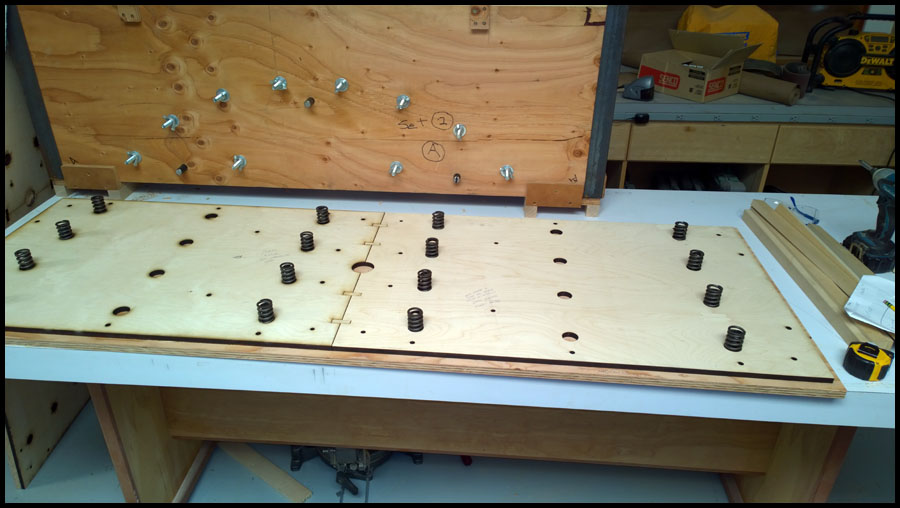

With the frog cut down and modified, Jenn was ready to start work. To build the turnout, we print out the the inverse of the Templot template

and then build the turnout upside down on top of it.

Nearly completed rail work for the turnout, and a proud Jenn showing off her work.

Now it is time for Jenn to make ties. This turnout is a long one, so it will take awhile…this picture shows that she is almost finished.

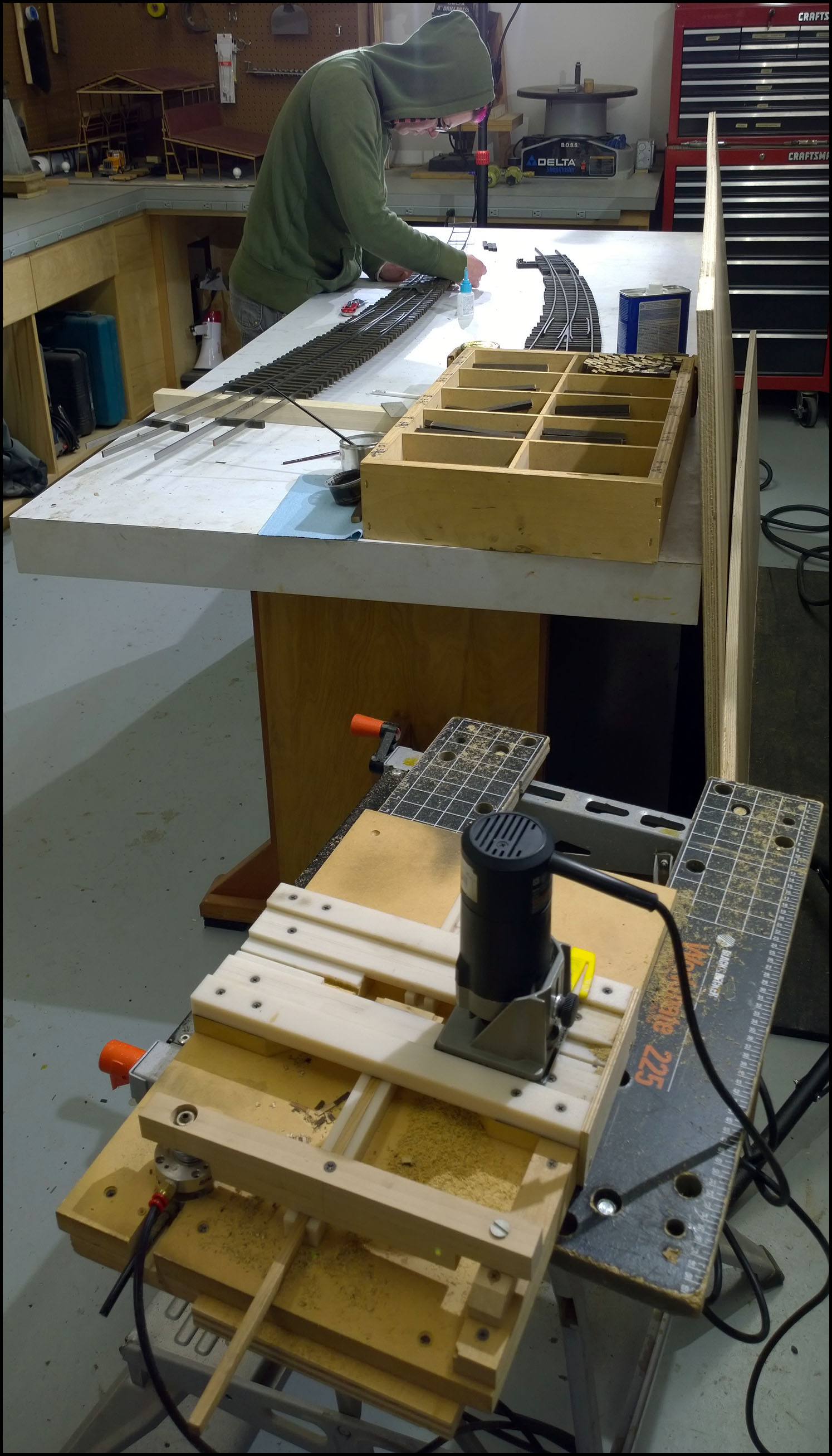

This next picture shows the clever router machine for making turnout ties. Jenn places a tie under the turnout and marks the rail positions as they cross the ties, then you can slide the tie into the slot in the plastic channel visible in the picture.

There is a long piece of unstained tie sticking out of the channel, we use this to help in locating the tie in place. The channel is hinged on the opposite side of the router. The channel swivels under the router guide, and when Jenn has it

lined up, she uses a foot peddle to activate an air solenoid that locks everything in place…then just slide the router across the tie. Sounds easy, but it takes practice and the router is loud, and the work repetitive, monotonous is the word.

Fortunately, Jenn doesn’t mind doing it so I don’t have too…

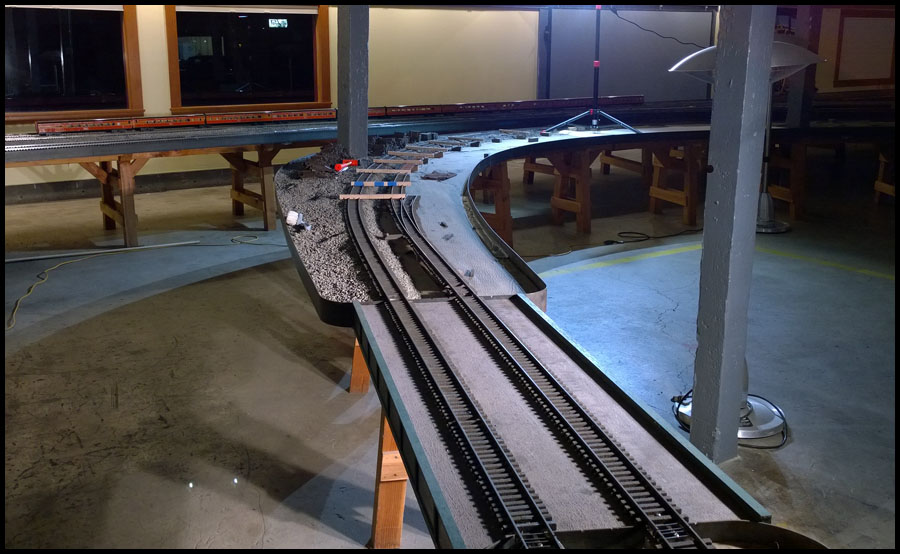

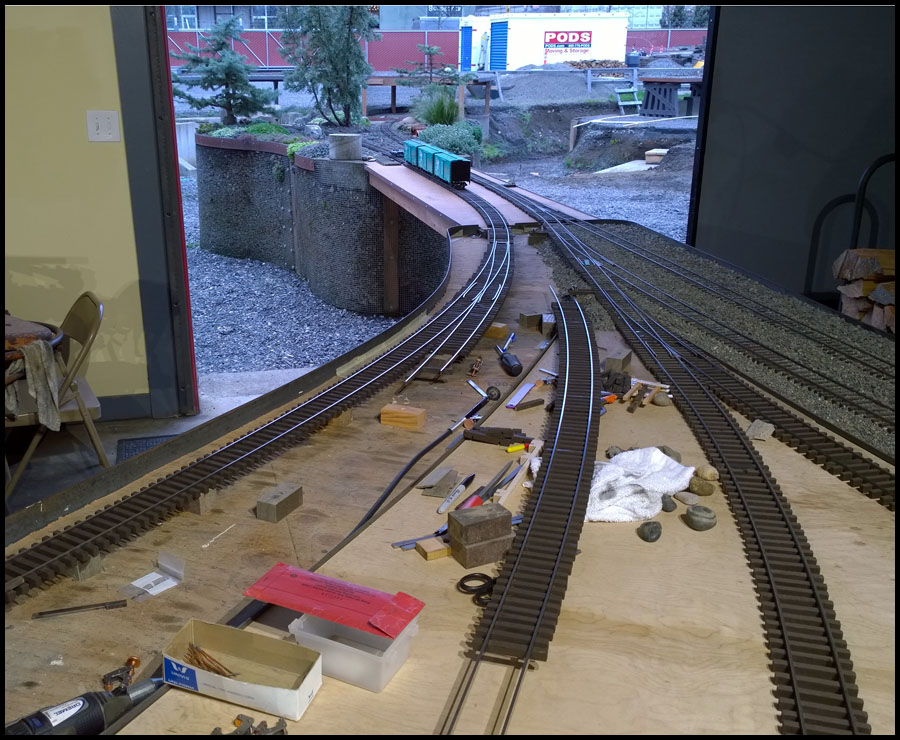

Time to install the turnout. Here is a rails eye view of the turnout in place.

From outside looking in…sorry again about the lens flare, shopping for a new DSLR, better photography soon.

From the other direction…

And here we are almost done. The turnout is installed, the alignment worked out nicely, so it was time to generate the transition curve and

build it to replace the existing curve and provide a short straight section before the diamond crossover.

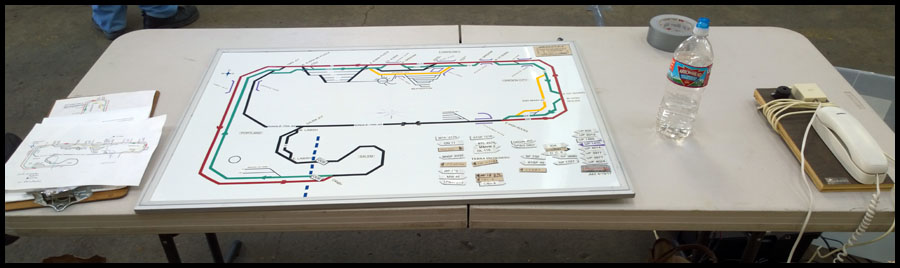

And finally, we now have enough information to start building the layout in Templot instead of just parts and pieces. We have enough hard

locations built with Templot templates, that I can take measurements, and very closely replicate the railroad in the computer. Since this work

was completed, we have measured and built models of the existing railroad, and we are using Templot to design the middle yards. I will, of

course, document this in later posts.

Back to the railroad…

Karl