Hi Greg:

As Dan wrote, you are mostly correct.

The rails do rust,and there is some added friction for long trains. As of now we usually do a light sanding of the rails before each event and the friction is decreased significantly.

When we build the extended outdoor division, it will be impractical to sand the entire track footage, and of course turnouts could be a problem with corrosion. We are experimenting

with a biodegradable product called “Fluid Film”, this product is used extensively in the marine industry to protect chains, cables, and hardware. So far I have sprayed some on a

turnout located on a short run we built outdoors and the results have been excellent. One treatment 2 months ago and the weather has only created a little surface rust. So our thought

would be to run a sprayer equipped train once a month or so outdoors.

We thought about using stainless, or a different alloy of steel more resistant to rusting. But we can’t over do it because Larry likes the rusty track look…so far the Fluid Film is working

and we will continue our experiments.

Battery power is not really banned, but it is a live steam railroad. However, live deisels, gas engine trains and such are allowed during steam ups. Larry has a few battery powered locos for kids to run.

He also runs them to pull cameras around the track(more on the camera additions later). Other than first Tuesday, there are no specific electric train events.

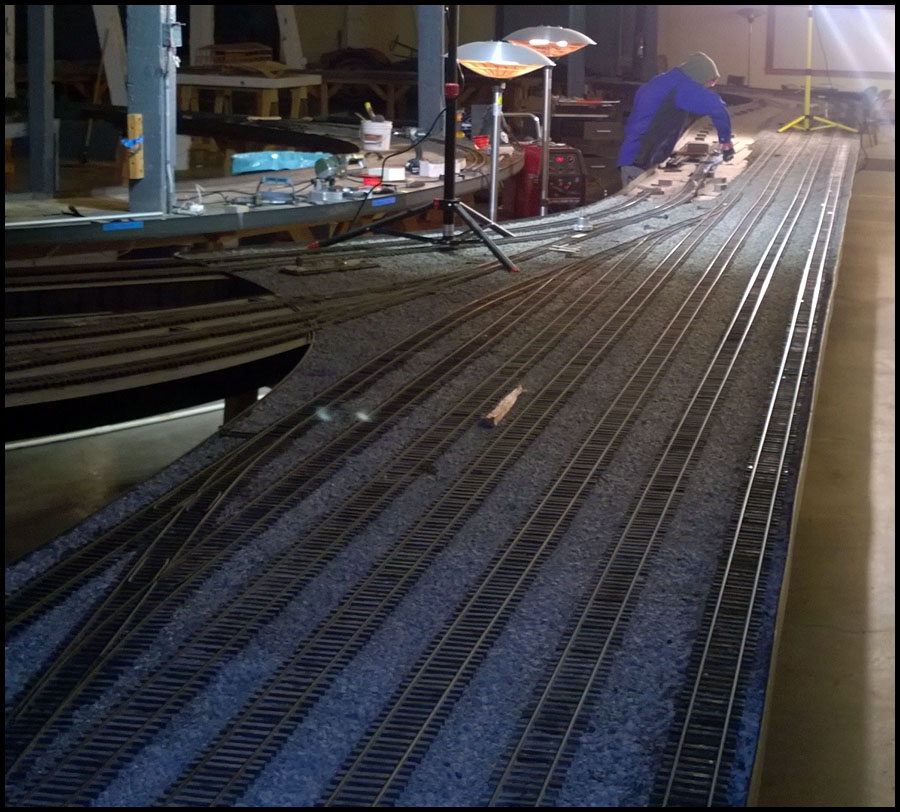

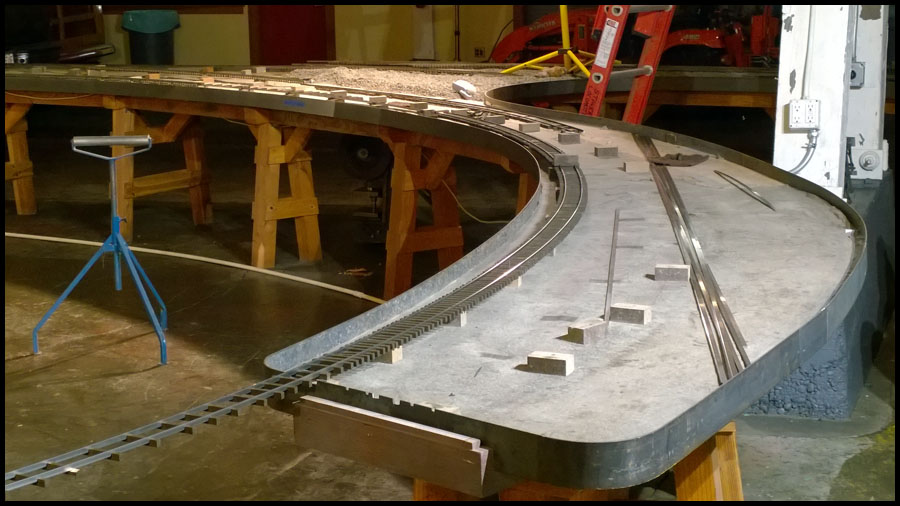

The railroad tables in the indoor facility are built the way they are so that the railroad can be cleared of all obstacles, including bridges and such. The facility is rented out for various events

during the year. There have been weddings, concerts, festivals, winery gatherings, art classes, music recitals, sales by manufacturers reducing inventory, charity events, and many others…that said,

the events only offset the cost of building the railroad. The track always remains in place, but fabric is used to cover the railroad if the event doesn’t call for trains to be run.

The facility also includes a commercial kitchen for catering events and music and art studio/gallery area. There are some planned modifications to the building to better facilitate seating for gatherings

in a climate controlled area. The wood shop will be moved into a new building that will provide storage for tractors and equipment, food handling and concessions area, and an upstairs deck for viewing

trains running through the outdoor railroad. The current wood shop will be converted into a storage and workshop area for the trains. This work is still in planning and drawing stages, so it won’t be finished

for a year or more.

At this time, other than first Tuesday operations, there are only three planned steam ups per year. However, we do sometimes have other events not regularly scheduled. If someone is in town they are usually

welcome to run if the railroad is in shape. Sometimes we just run trains because that is what model railroaders do from time to time. But also, Larry has been experimenting with some Raspberry Pi’s and

micro HD cameras. The plan is to have cameras around the railroad, and you can go live and watch them from the web site. Also trains will have live cameras in them. It is mostly working now after

some time getting fast and good enough Wifi to handle all the streaming. We had a steam up this summer open to the public to test the system and judge interest.

We have a small but dedicated crew that keeps Larry’s facility running. Only three of us typically work on the railroad. Joe pretty much handles infrastructure outside, and spends most of his time preparing

the property for the outdoor railroad. He is a very hard worker and quite good. Jenn and I are the builders of the railroad. Although we love model railroading, real railroading, and especially live steam, we are

not independently wealthy, and Larry has to actually give us money from time to time.

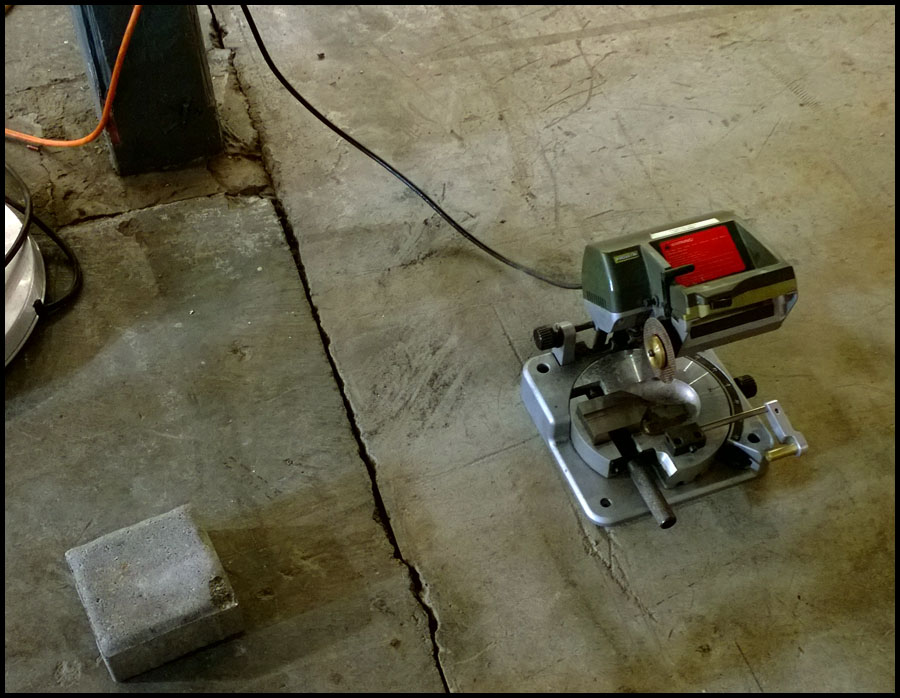

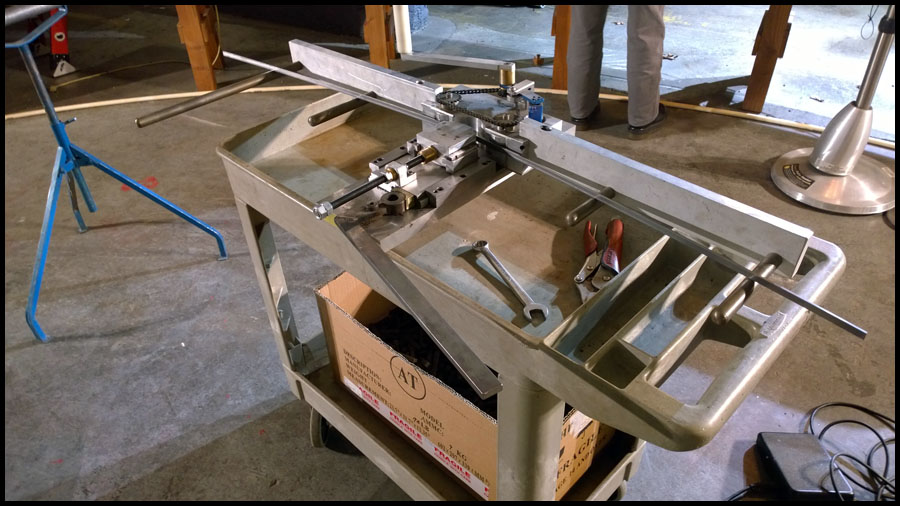

My skill set is almost uniquely perfect for Staver Locomotive. Jenn and I own a machine shop/live steam manufacturing facility and many of you are probably running my products without realizing I invented and manufactured

them, such as Accucraft replacement steam regulators and fine adjust gas needles among many others. Although I spent most of my life self employed, almost everything I have done provided skills I use at Stavers.

35 years experience working on, racing, and tuning old cars, especially muscle cars. Carburetors and ignition my specialty. After meeting Larry over ten years ago, one of the first things I did for him was fix

and tune his Plymouth Woody and ancient farm tractor.

From 1990-2000 I owned one of the largest slot car raceways in the US. During this time I designed and manufactured laser cut chassis’ for 1/24th slot cars and became very skilled at the use of lasers in manufacturing. Also

began purchasing automatic machines for manufacturing slot car parts. For a few years, I also designed, manufactured, and sold RC pylon racing sailplanes for slope soaring.

Worked as a millwright in the paper and steel mills throughout Oregon and Washington, so facilities maintenance, rigging, machine maintenance and installation, allow me to handle any facilities problems that arise.

Supervisor and manager of a large industrial machine shop in a factory in NC making air tanks for Freightliner. 900 tanks a day. My crew produced up to a half million parts a year for these tanks. Gained experience

in large scale manufacturing using and repairing everything from giant 1930’s multi spindle screw machines, to modern cnc lathes with live tooling.

Supervisor of CNC maintenance at a large military contractor and steel company in Portland. Here my crew and I did all sorts of stuff, but primarily I installed and repaired cnc machines, high powered plasma cutting

machines, and up to 6000 watt lasers used to cut armor plating for military vehicles. So keeping lasers and machines running at full efficiency is right up my alley.

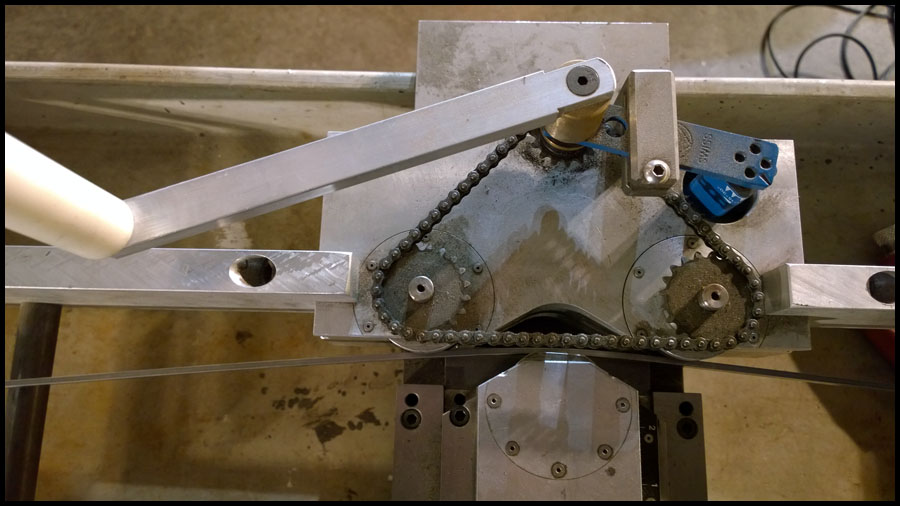

30 years experience in micro controllers and embedded electronic controls, I can program almost any kind of computer, from assembly language to modern versions of C used for Arduino’s and such. In fact, we have some

turnouts on the railroad controlled by an Arduino that I built because you cannot reach the manual switch levers.

And of course, it helps that I have been a model railroader as long as I can remember. Grew up within hearing range of the whistles at the Roaring Camp Railroad in the Santa Cruz area of CA. So steam kinda got boiled

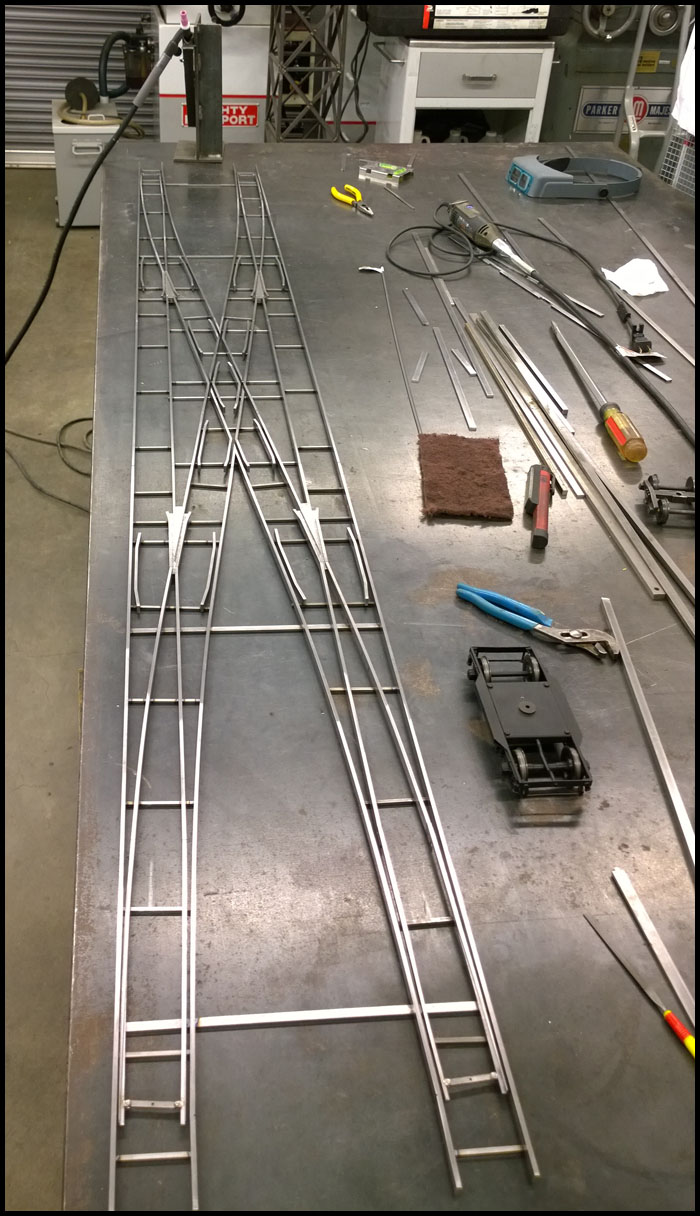

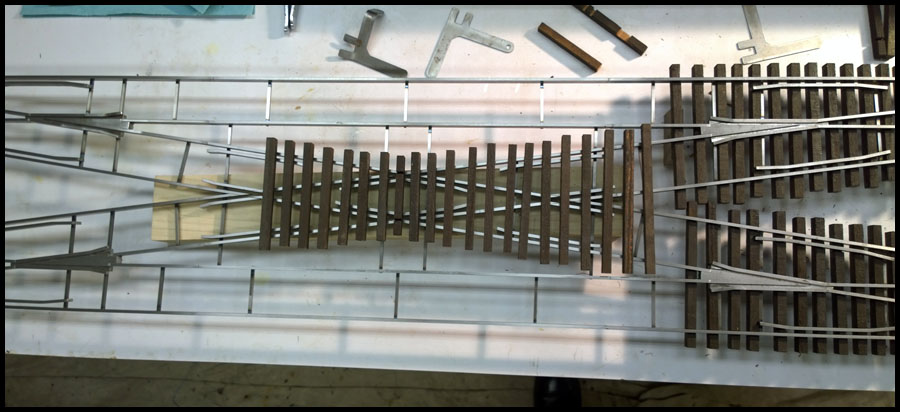

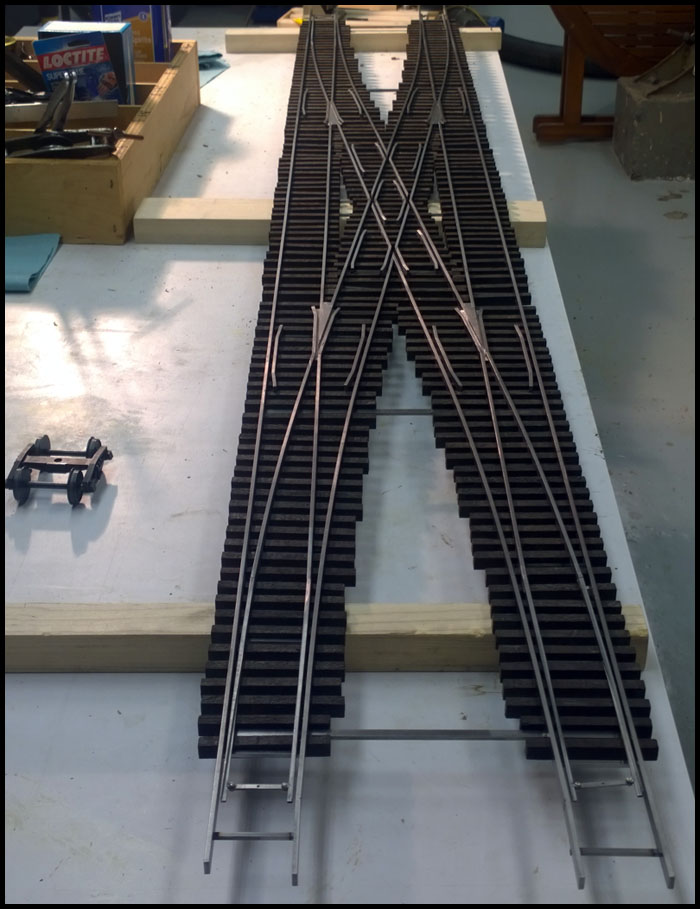

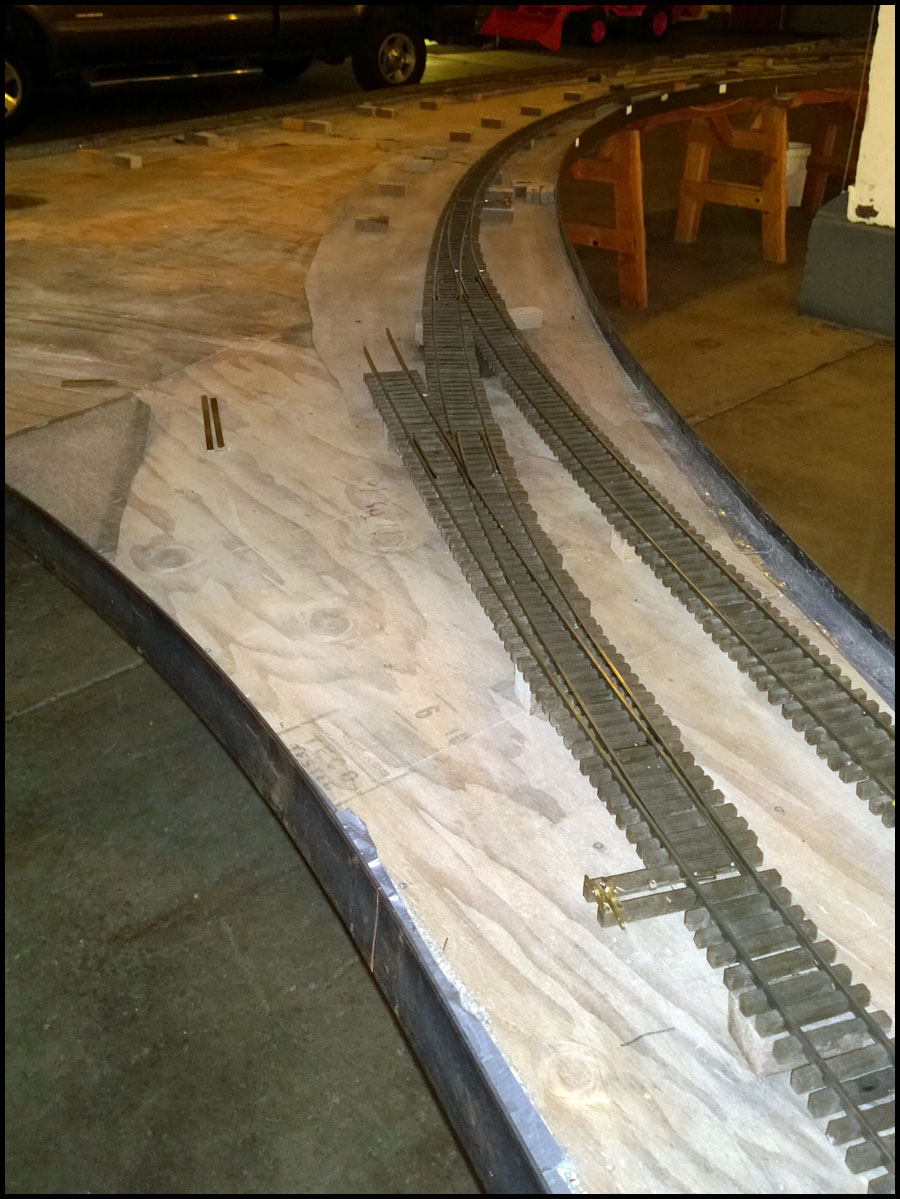

into my blood at an early age. My model railroading includes scratch building turnouts and hand laying track for many years in my youth. (Side note)-Jenn and I were fortunate enough to ride in the cab of the shay at Roaring Camp over

Thanksgiving weekend while we were visiting family in Felton a couple months ago.

I started building my first live steam engine when I was in middle school, still have the parts I made. Almost everything I’ve done in life was to get to where I could have my own machines to build steam engines, I never

imagined I would be lucky enough to grow up and have a Staver Locomotive in my backyard, and be fortunate enough to meet and become friends with Larry, and have the skills necessary for Larry to be willing to pay me

to work on his railroad.

Jenn is a very smart woman, with three degrees and experience in many different areas, including working in a steel shop previously. She has lived off the grid in Alaska, and I will depend on her to shoot and kill our food when

the apocalypse comes if ever… She can run the machines in our shop, or the ones at Stavers, at least as an operator if not the setup and programming. And she has very steady hand for welding intricate assemblies. I am also

very fortunate to have a young, beautiful, and talented wife capable of working with me in all our endeavors.

Larry also likes to have the people who work for him have other sources of work and income. He doesn’t always want to work on the railroad full time, and it is nice for him to know that we won’t be in a soup line if he decides to

take a break for awhile.

All in all, working for Larry is a choice gig, and I can’t thank him enough for the opportunity to help him build his railroad any way he chooses.

Hope that answers most questions. If I left anything out, I would be more than happy to answer any others.

Thanks

Karl