Update:

First, @David_Marconi_FOGCH , thanks for the detailed way forward. For now, I have Kid-zilla focusing on the mechanical part of the AM-Critter. I figured if he can get it rolling, it will keep him rolling! I also don’t want to get in a situation where he has built everything only to find some internal issue isn’t quite right. That is always demoralizing. I figure closing the back will be the first major step prior to paint and external details. Oh, and yes, @Rooster , we have the card ends and PVC board.

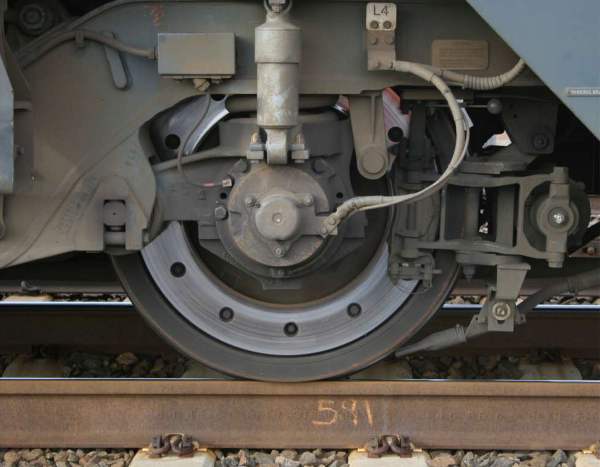

Second, the motor block confounded us for a bit. Those jumpers should have worked. Kid-zilla began by opening up the block…

…and inspecting the internals.

We even tested the motor. No worries. We saw no bent bus bars or loose solder joints. Kid-zilla hit upon the idea that you had to jump from port to starboard across the block. I didn’t think it mattered, but, what the heck, and lo! it worked! Strange…For kicks, we removed the motor, inverted it, reinserted it, and replaced our jumpers. Turned right over. Weird…There is a reason I barely passed electrical engineering eons ago.

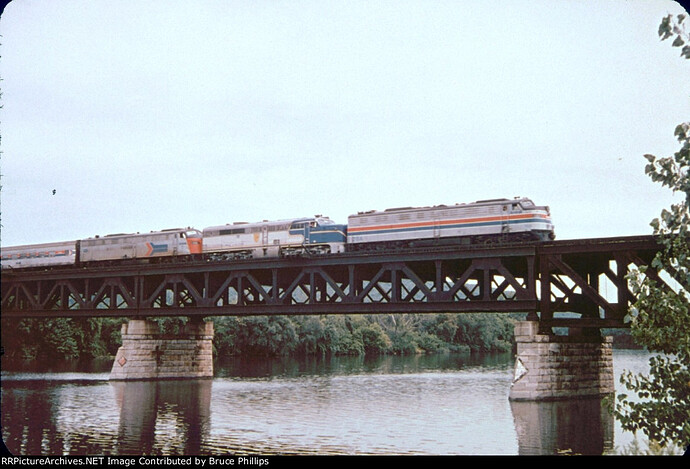

Next came the all-important on-track test.

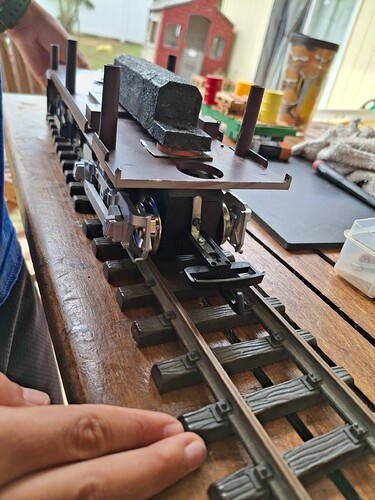

He noted that the drivers spun on the rails, and he quickly deduced it needed more weight, but how much? He grabbed a B’mann 4-6-0 weight (Thanks, @John_Bouck !), removed the motor, and tried again.

Success! Next, of course, came a partial reassembly to see this thing roll (video)!

The following day we were off to the hardware store for some nylon washers to properly mount the weight and the trucks. This required a full disassembly.

I should add we also got the requisite aluminum paint!

We got a couple extra washers to see how AM-Critter sits on the rails. One washer gave the following results:

Two washers looked sort of silly to Kid-zilla, as the cab rode high above the motor blocks, so a bit of filing is in his future!

He can file with the best of them. I did tell him he has to think about how to add couplers so that AM-Critter serves an economic purpose. One hurdle at a time!

On Behalf of Kid-zilla.

Eric

P.S. My role remains one of safety and the prevention of catastrophic failure. Most of the troubleshooting and solution generation is his.

) and liquid plastic glue to slowly build up his shim sheet by sheet. In the end, he got it, drilled the pilot holes, and mounted the forward coupler.

) and liquid plastic glue to slowly build up his shim sheet by sheet. In the end, he got it, drilled the pilot holes, and mounted the forward coupler.