I got a few buildings inside to refurbish while the rain hit. Now that’s the sun’s back I can get them back out.

Startin to look like something…(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

I got a few buildings inside to refurbish while the rain hit. Now that’s the sun’s back I can get them back out.

Startin to look like something…(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

It certainly is Ken. Love what you have done with this new version of your RGS.

Looking good Ken. The buildings are bringing it to life.

Have you considered a few 7’ uprights on the outside edge and a nice 6’ wide piece of material for a custom awning over this section. Secure it to the trees in the back and let if protect you from the pine needle growth(http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)(http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

The pine needles don’t really bother me all that much. They tend to stand out against the black plastic, but once I get the dirt down you hardly notice them. In some parts of the country they’re considered mulch. I do get a few sticks and twigs, but I was expecting that.

Once spring arrives I’ll also be planting more shrubs and trees, so I don’t want to be blocking any rain fall that hits the area. When I was down Bruce’s a few months ago he has a very fine mulch on his layout. I’ll have to see if any places around here sell the same kind of stuff. That’ll help keep some of the dirt splash down.

looking real good Ken, when you do your plantings, are they in “pots” buried in the dirt/mulch or just planted like normal? I’m also wandering if winter that will be too much to take for plants that don’t have their roots buried in the ground? Being raised up that layer of soil they are in will be froze rock solid with no cushion from the “warm” ground deerper. keep hustling!

Buildings sure do make a difference… Of course, once the dirt is added, it will also enhance the appearance greatly… (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

Nice work…

Randy Lehrian Jr. said:

looking real good Ken, when you do your plantings, are they in “pots” buried in the dirt/mulch or just planted like normal? I’m also wandering if winter that will be too much to take for plants that don’t have their roots buried in the ground? Being raised up that layer of soil they are in will be froze rock solid with no cushion from the “warm” ground deerper. keep hustling!

Depends a lot on the plant. I planted a few sedums and just planted them right in the dirt. We’ll see how that works out, though I’m sure, even in the ground the frost goes down below their roots. The larger stuff I left in the pots, cut the bottom of the pot off and just sliced a hole in the screen, set the pot in and filled all the way around it with dirt.

A few others that I planted outside the layout I did the same thing, cut off the bottom, set it on a pile of dirt, then mounded more dirt around it.

We’ve had frost reach 1-2’ most winters, and most of the smaller plants have survived that.

Never let a gorgeous day go to waste.

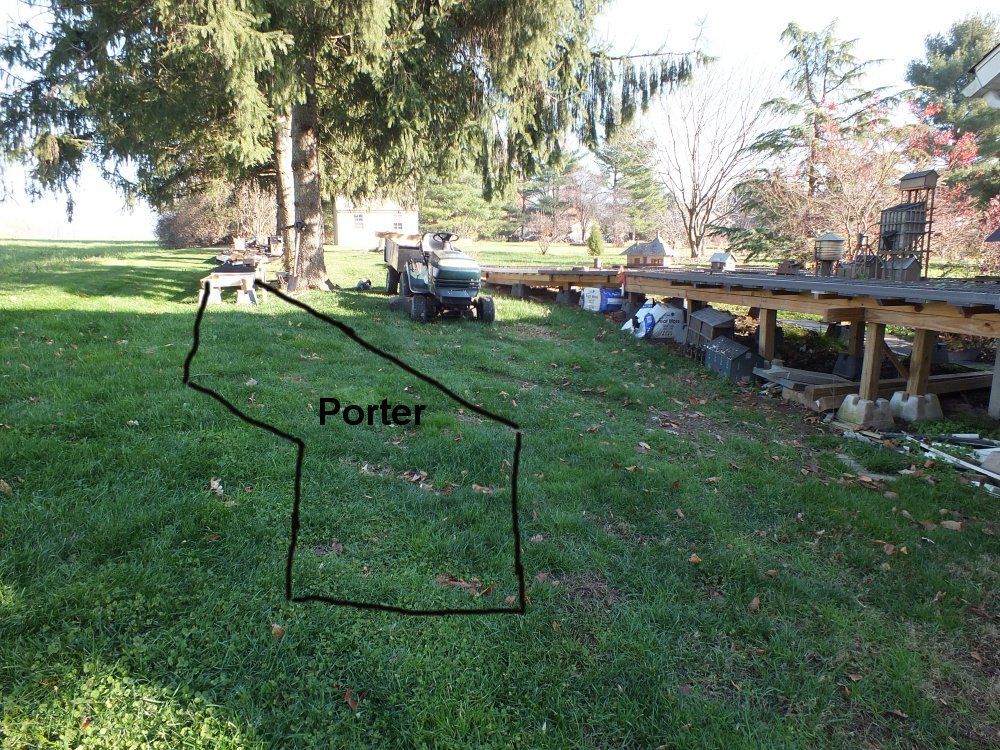

The plan is to start the wye at the end of the tree line and head towards the tractor and connect with the first yard track in Delores. The module I worked on today is the same height as the yard opposite the tractor.

http://www.largescalecentral.com/articles/161/part-5-a-raised-roadbed-on-to-porter

Geez, if you keep going at the pace your at your gonna catch up to Jane & Andy. Just kidding, it looks great Ken, You will have to have Bruce up soon so you two can give it a go, You have enough track down to do an ops maybe.

Ken, your an animal ! You’re really taking advantage of this late winter. And things just look better end better. The shots with the dirt and a few plants are right on. Sounds like you’ve got a good plan for planting, and I have to agree that things should stay green with what your doing. Two green thumbs up! (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

Lookin good, Ken…

Randy McDonald said:

Geez, if you keep going at the pace your at your gonna catch up to Jane & Andy. Just kidding, it looks great Ken, You will have to have Bruce up soon so you two can give it a go, You have enough track down to do an ops maybe.

I’ve been fortunate that the weather for Dec isn’t the usual 30’s and 40’s. More like the mid 50’s to low 60’s. I can handle that. And probably the day I decide to invite Bruce up for an Ops is when the blizzard will hit…(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

I’ve had 2 or 3 Ops already, just to get the glitches out of the software. If this nice weather stays around I’ll have to get something going to try out all this new track work.

Sounds like you’ve got a good plan for planting, and I have to agree that things should stay green with what your doing.

That was one of the main reasons I wanted the layout closer to the ground although I’ve never kept anything in it’s pot before when I planted it. I did plant a sedum up near the water tank in Delores and built a box for it that I attached under the layout from PVC board. Another experiment I’m trying out…(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

Since I’m getting prepared to go down this road, I have a very basic technical question.

If memory serves me Richard Smith uses hardware cloth to support weed block fabric to hold his dirt and ballast. In your article you said…

On top of these will be a 1/4" plastic mesh screen used for fencing with window screening over that.

Can you explain the reason why you went with the plastic fence and window screen (I assume this is also the plastic variety) over the hardware cloth and weed block? I’m thinking it may have been a cost thing, or maybe trying to avoid sag in the hardware cloth, but would love to hear your reason.

I used that mainly for drainage, Jon, and the plastic fencing is cheaper then what I regard hardware cloth to be as a galvanized 1/4" screen. And a roll of that being plastic is a lot easier to work with then the metal stuff. In some places a module is 2’ wide and the plastic is 4’ wide and it can trimmed easily with a utility knife. Also the mesh being plastic it’s easier to cut through on those modules that are closer to the ground so planting trees and shrubs can be placed directly on the ground in their pots and dirt added around them. I can use a utility knife to slice and “X” in the screen and set a potted plant in there without the hassle of having to bend a wire screen down and my hand getting sliced up on the sharp edges. The window screen can be either the vinyl or aluminum, I’ve used both and both are easy to slice. It was mainly a cost and ease of use thing.

Thanks Ken - I did look at Lowes and the plastic stuff is about half the price of galvanized, and like you say, much easier on the hands, so I’ll go with you there, but for topping I think I’ll stick with weed block fabric. It’s much tighter than screen, so I’d expect to loose much less dirt/ballast dust over time as I would expect with window screen. I need to start stockpiling patio blocks and post blocks so all I’ll need to start is wood. If I work slow I can probably come up with all the PVC I’ll need as scrap from work. I already have a garage full of the stuff.

With the top screen it was an either/or thing. The alum. or vinyl just seemed to me to be easier to work with. And tell you the truth, I haven’t noticed any dirt leaking through it, especially since we’ve had quite a bit of rain.

Glad I could be of service…(http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

Just a point of clarity; I have, and Richard does, use 1/2 inch hardware cloth which is a little less expensive than the 1/4 variety.

And you are correct it is a flesh eating material if your not careful.

I found on the 1/2 inch with support every 16 inches on center it was still subject to a certain amount of sag over time. Curious to

see how the plastic netting works for you as I am going to be rebuilding next Spring.

Rick

Don’t Yunz have an issue with the hardware cloth rusting? I know its galvanized, but over time that will wear away. Ok, it has for me in my applications.

Just as a point of clarity:

I used 1-1/2" by 7/16 to 3/8" cedar laths I cut myself joined about every 8" with PT blocks for roadbed because it is can bear weight without sagging. None of the plastic or PVC products are structural and must depend on what’s beneath for support. Thus even though the hardware cloth sags a bit with time the roadbed does not as it is attached to 2x4 cross members every 16". To accommodate the scenery sag just add more dirt or ballast. Eventually the hardware cloth will reach its maximum stretch and sag no more. I did add additional support everywhere I installed large rocks.

The cedar lath is heavily primed especially on the ends and coupled with the drainage due to being elevated has held up very well. The landscape fabric drains slowly but it does drain keeping things pretty good. The only place I’ve had to replace any roadbed was in two spots each about 12" in length (I replaced 24" to give good connection between new and old). These sections had warped a bit creating a hump and were both in the oldest part of the railroad or about 9 to 10 years old.

It was easily replaced by digging out around the roadbed, cutting out the sections, screwing new pieces to the ends of the still solid older parts and covering up with fill material again.

I have been quite satisfied with the performance of the wooden roadbed. Of course I didn’t skimp on material quality or prep. But that should be the criteria whatever the method used. It is after all the very foundation of the entire railroad and everything else is dependent on its performance.

I have noted a few people that seemed to think you could just lay track on top of the fill and not even use roadbed. That would be a mistake. Perhaps after the hardware cloth reached its maximum sag in a few years that would be possible but I still wouldn’t do it that way unless I was building a roller coaster. (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-surprised.gif)

Hope this clears up a few points from my perspective. (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-smile.gif)

I have had no problem with rusting of hardware cloth in 11 years now. Of course if the material is in constant moisture you might have.

The master has spoken!

Edit: Because I’m still waiting on that smoked salmon and peach pie you promised me a few years ago ole’ man…(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)