I have the steel boxcar book, Ill probably use that for the poling pockets. I made them years ago as a resin casting for my boxcar kit but cant find my mold now.

Rough assembly to make sure everything is lining up. A couple tweaks to the slope sheet, but the sides and ends look good.

Here’s the design of the center beam and how the aluminum channel interfaces with it

And the channel on the end by the coupler pocket. I’m thinking for strength some kind of thin steel tang that both attaches to the channel and the rear screw of the coupler pocket.

Wow that all looks so good, Bob. You’ve really nailed the FDM processes, interlocking design technique, and incorporation of stock materials. Sweet.

The PSC hoppers were longer - 25ft - than the 4 later Rock hoppers.

I made an Fn3 2-bay from 2 Bachmann plastic Big Hauler hoppers.

So what was #906 classified then?

Creeping up on the design of the middle hopper sheets and doors. The middle part has a double-sloped peak, but I want to get the overall proportions correct and then work on that.

The PSC 2-bay hoppers, being longer than the later ‘rock’ hoppers, were apparently found to be unstable. They were all rebuilt into 3-bay hoppers.

I think a few PSC 25’ hoppers would be a great printing project!

I think the one you posted is an original PSC, per the photos.

Bob,

The picture you show is the stenciled number not the original?

Pete is correct from about the rebuilds of the Pressed Steel Car from what I know (which is minimal).

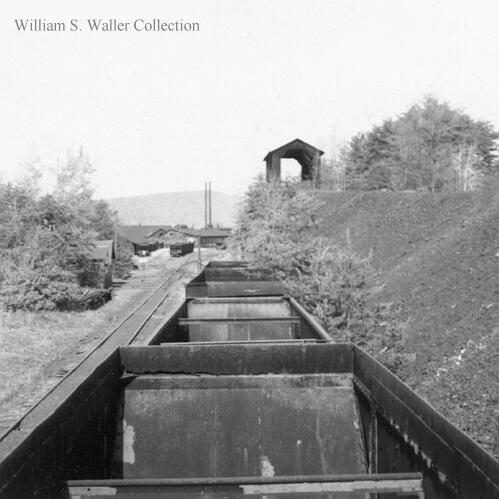

My picture was taken at the same location as this one and appears the same consist was still there from my 3yr old pic.

I think this is the final design of the center bits. Took five prototypes. It’s currently on the printer, we’ll know in a few hours.

Yup, that fits. And will provide some decent strength side to side.

And in this view you can see how the aluminum channel fits inside.

Bob

Doing a EBT 25’ 2 Bay would be something different and real interesting.

802 was one of the first batch of PSCC 2 bay hoppers built in 1913 which was later converted to a side dump car.

I have an underside photo of another EBT 2 bay if that helps.

Stan

If you (or someone) has a picture of the bolsters, that would help.

Perfect, thanks. That answers a lot of questions

Wow Stan, that’s a shot almost never seen for any car! Nice!