Some notes on what I just wrote.

I’m trying to finish a number of yard and lighting projects, which take precedence. But I really need to get this trestle done! So the interchange here helps motivate me.

This process has been all about forcing everything into known geometry, from both the site side and the workbench side, to the degree possible. I can’t afford 3D laser scanning of the site, but have tried to get a reasonably good data set with template-based measurements.

The 1/2" nominally thick cedar slabs beneath each bent will be adjusted to suit the tolerances.

The pier jigs are greatly simplified, basically down to pieces of acrylic representing the pier top surfaces, all suspended from the existing (and still quite accurate) plywood deck.

For the pier form, I’m planning on using Precision Plastic sheet, cut in ~2" tall strips and bent around that suspended acrylic rectangle. The PP sheet will be from stock obtained from both Bruce and Ken.

The benchtop build base will be cut from lasered cardstock patterns (you can’t cut that foam directly with a laser).

Bent jigs will have lasered parts. The deck will have a laser cut / marked template.

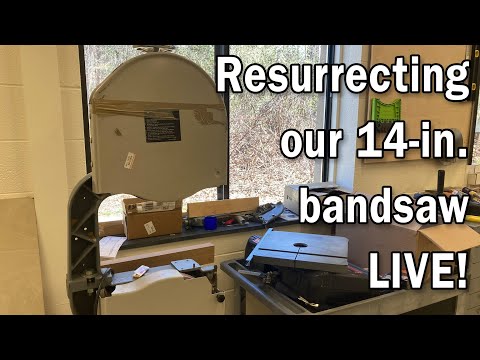

ALL wood parts will be hand-cut and assembled, from ripped cedar. The 100’s of feet of cedar ripping will be done by a Grizzly 14" bandsaw, now on order.

Joints will be using TiteBond II (I’ve read it’s better than III for outdoor use??) and a pin-nailer.

Rail will be code 332; no guard rails; hand spiked with a spiker tool Bruce gave me (thanks Bruce!!) and steel spikes Rooster gave me (thanks David!!).

Well, that’s the plan.

Cliff