I have several various types of “passive” track cleaners, including manual, railcar, and engine, but none of them “spin an abrasive” like the LGB track cleaning engine.

I did have one of those, but it was troublesome, even after LGB “fixed” it, and the abrasive disks have gotten so expensive as to be prohibitive (>$20/pr and I could go through a couple at a time).

I figured that there had to be a more economical way to accomplish this.

There is a company (Cratex) that makes rubberized abrasive disks in various grades, diameters, widths, and chuck holes.

https://www.mscdirect.com/product/details/41168642

On the bay I found a seller and paid $51 for 100 medium grade disks with a 1" diameter and 3/16" width for a 1/8" arbor.

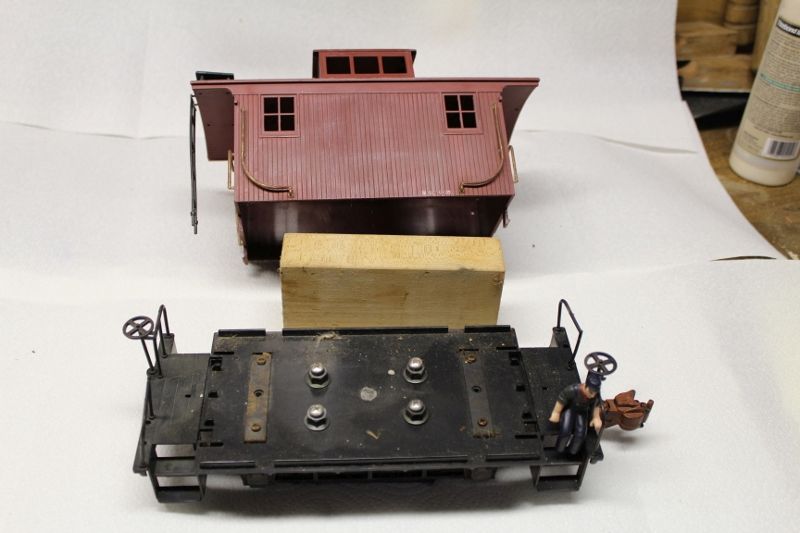

The idea is to find a motor that could fit a wheel to each side, yet fit within the confines of the track, working voltage, mounting provisions, size limitations, etc.

There was no way to find such a motor with a 1/8" shaft on both sides.

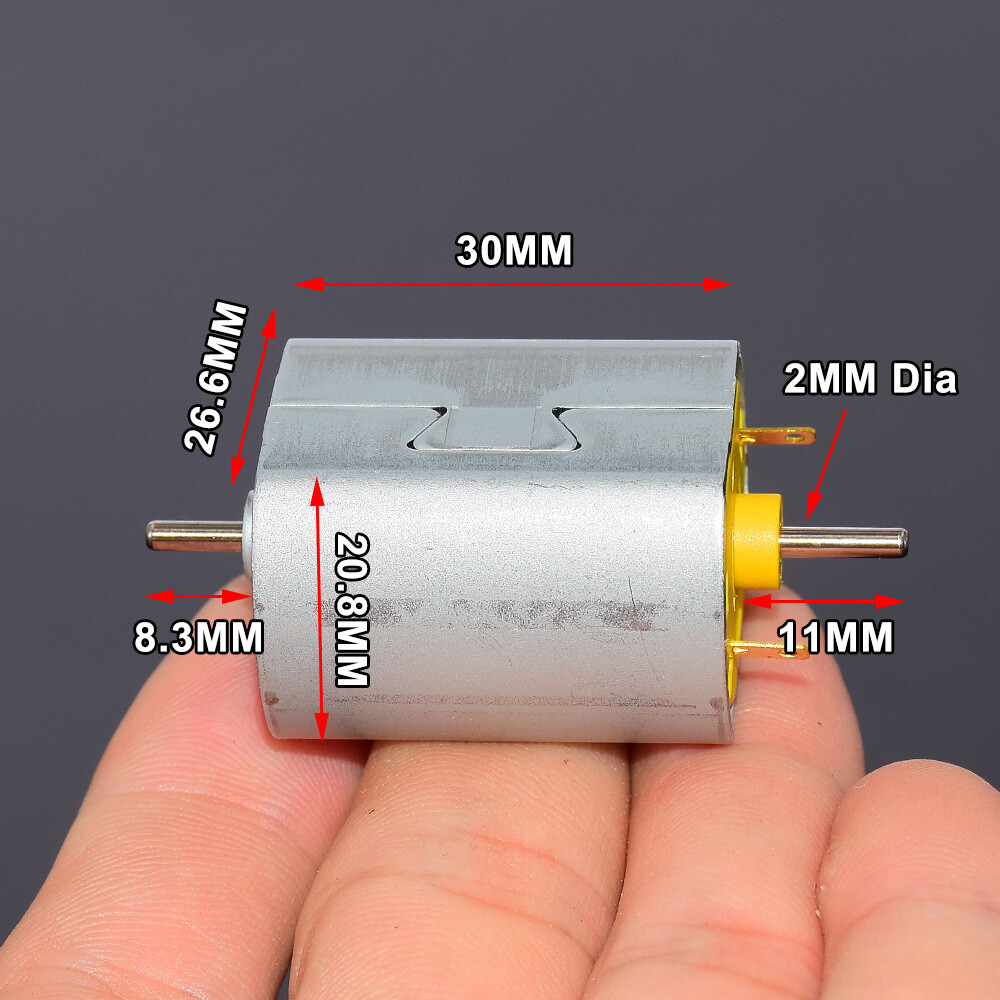

But, I got one of these. They are 16 volt (about perfect) and have two 2mm shafts and spin at 11,200 RPM (unloaded).

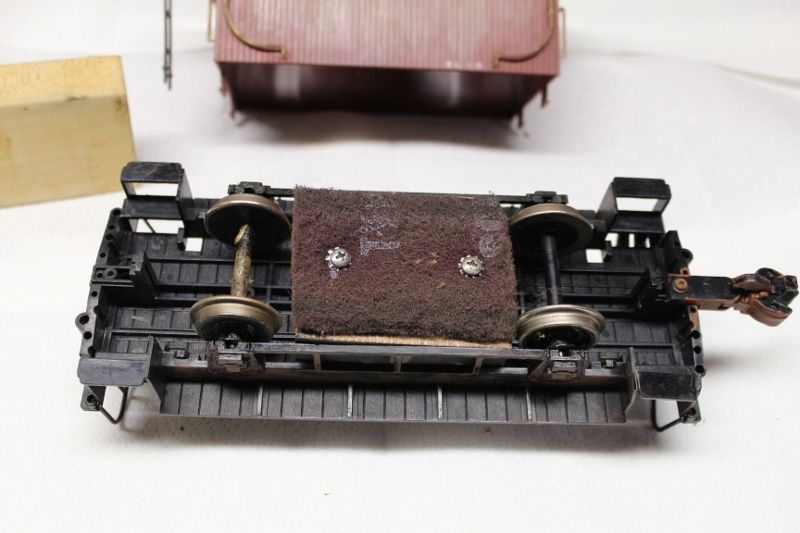

The height (20.8MM or 0.81") is less than the 1" wheel diameter, so I should get >0.2" of wear before the motor drops to where it would drag on the ties.

To compensate for the 2MM shaft, I ordered a piece of 2MM ID, 4MM OD stainless tube that I can slip over each end. 4MM is about perfect for the large radius of a 5/32-32 nut which is very close to the wheels’ 1/8" arbor hole (which is probably oversized anyway). Alternatively, it could be turned down to a 1/8" center.

The parts are only available out of China, and have been ordered, but shipping will take some time. Once these arrive, I can work out a set of trucks to contain it.