As you know, I have another thread going about the “little short line” I’m building to go around our home (for the grandkids, of course :)). Well the new railroad needed some added power to do some “switching chores”. This Super Husky (available from Eaton Custom Engineering in Castle Rock, WA.) fits the bill. Only weighs 150 pounds ready to run and is made of 6061 T6 aluminum plate. Has two small automotive batteries (Group 26) and is powered by a single 500 watt, 24 volt motor through chain drive to all four wheels. This engine can be lifted by two people and put in the back of a SUV with room to spare. Completely wireless controlled with Phoenix Sound exactly the same way we run our garden railroads. Pretty nice package and a strong puller. There is a video on the website that shows this single engine pulling 11, 1-1/2 scale gondolas. Very impressive for a loco this small.

Today I picked up the aluminum material from a friend who got it for me, to begin the chassis build. I returned the pieces I needed to be sawed to my friend this afternoon at the Los Angeles Live Steamers facility. Once they are rough sawed, I can start to mill the pockets for the journals and fasten the pieces together with bolts and nuts and 1 X 1 X .125 thick aluminum angle stock.

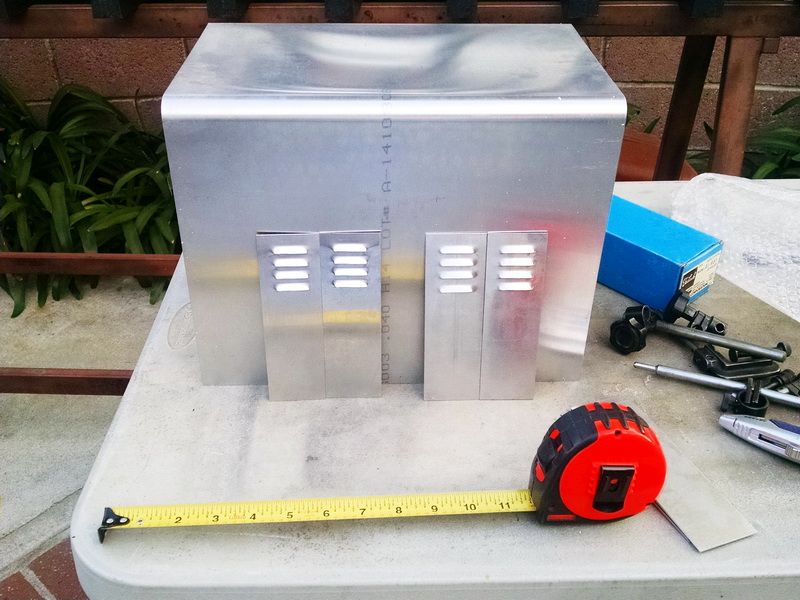

To get a comparison of size of this engine, that’s a 36 inch square head blade laying on top of the stock. 1/4 inch thick aluminum.

In the back of the car, ready to take to LALS and turn over to my friend to do the saw cutting.

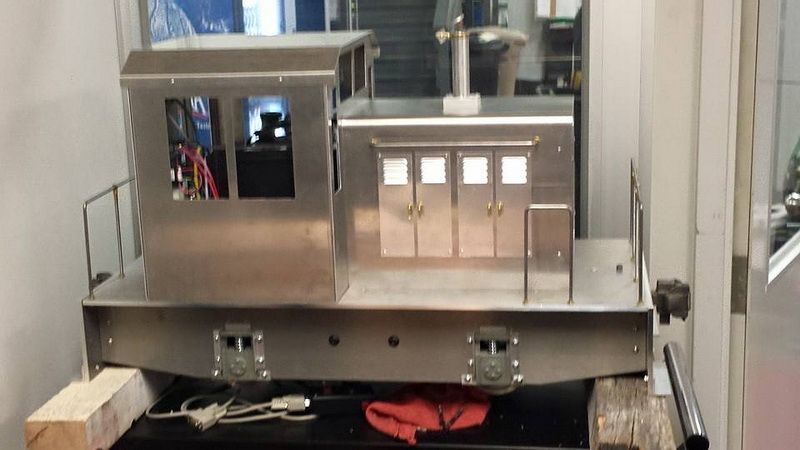

A couple of photos of the finished engine. When completed, it will look exactly like the old MDC model in “G” scale. Remember the Lil’ Hustler?

(along with all the other mechanical items). The axles have 1.125 diameter ball bearings on each end and self-aligning flange ball bearing on the idler shaft under the chassis. All four wheels are chain driven.

(along with all the other mechanical items). The axles have 1.125 diameter ball bearings on each end and self-aligning flange ball bearing on the idler shaft under the chassis. All four wheels are chain driven.