When you hear the words “dog park” you naturally think of a park-like setting with dogs playing with other dogs and their owners.

But when you hear the words “car park” your mind goes to a parking lot where people leave their cars so that they can go about their business. A really nice parking facility would offer other amenities, such as “detailing” and such.

So what if one were to merge the two so that people could have their dogs parked and/or serviced while they mull about town? And wouldn’t it be nice if this was a mobile service?

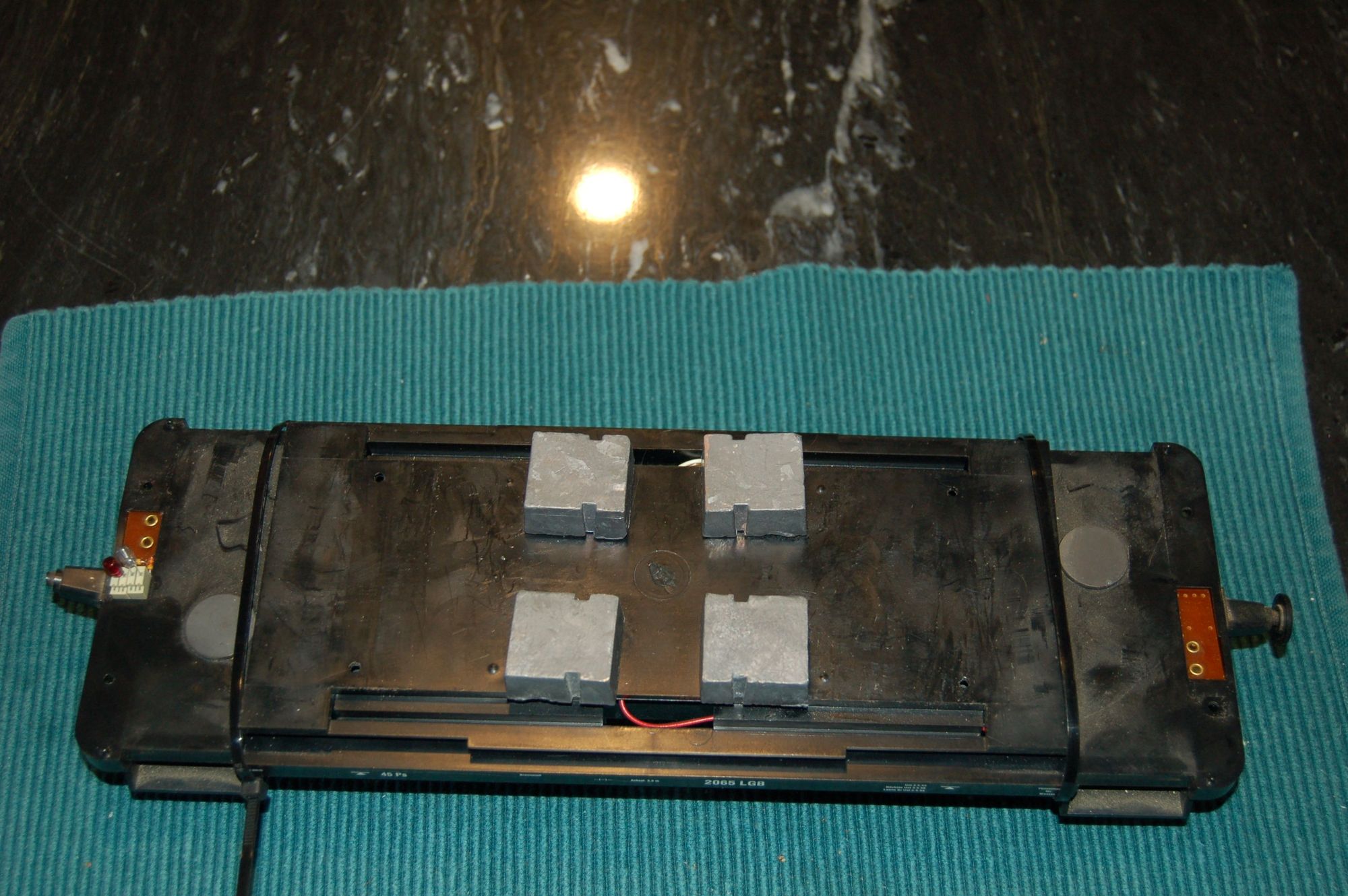

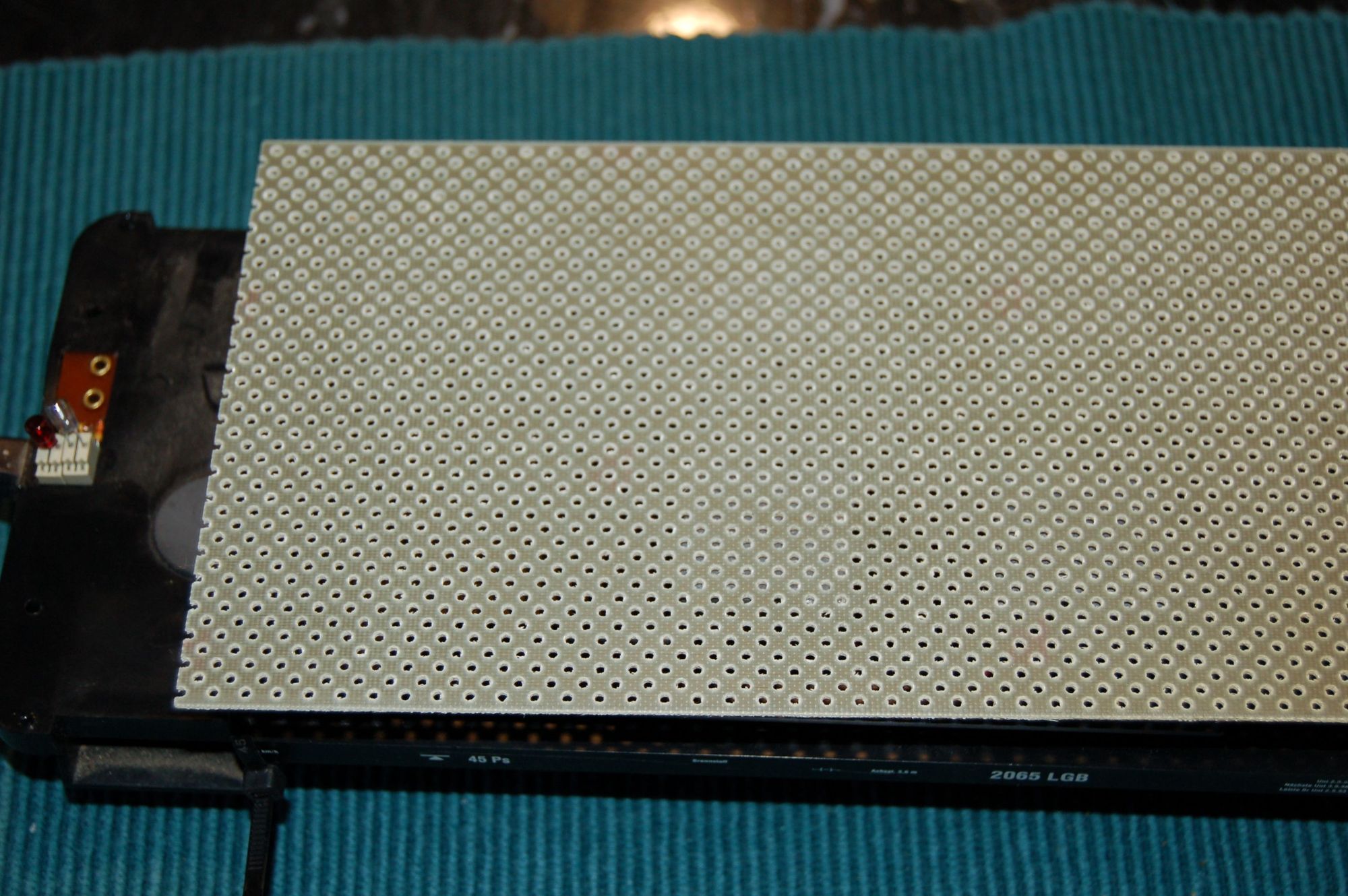

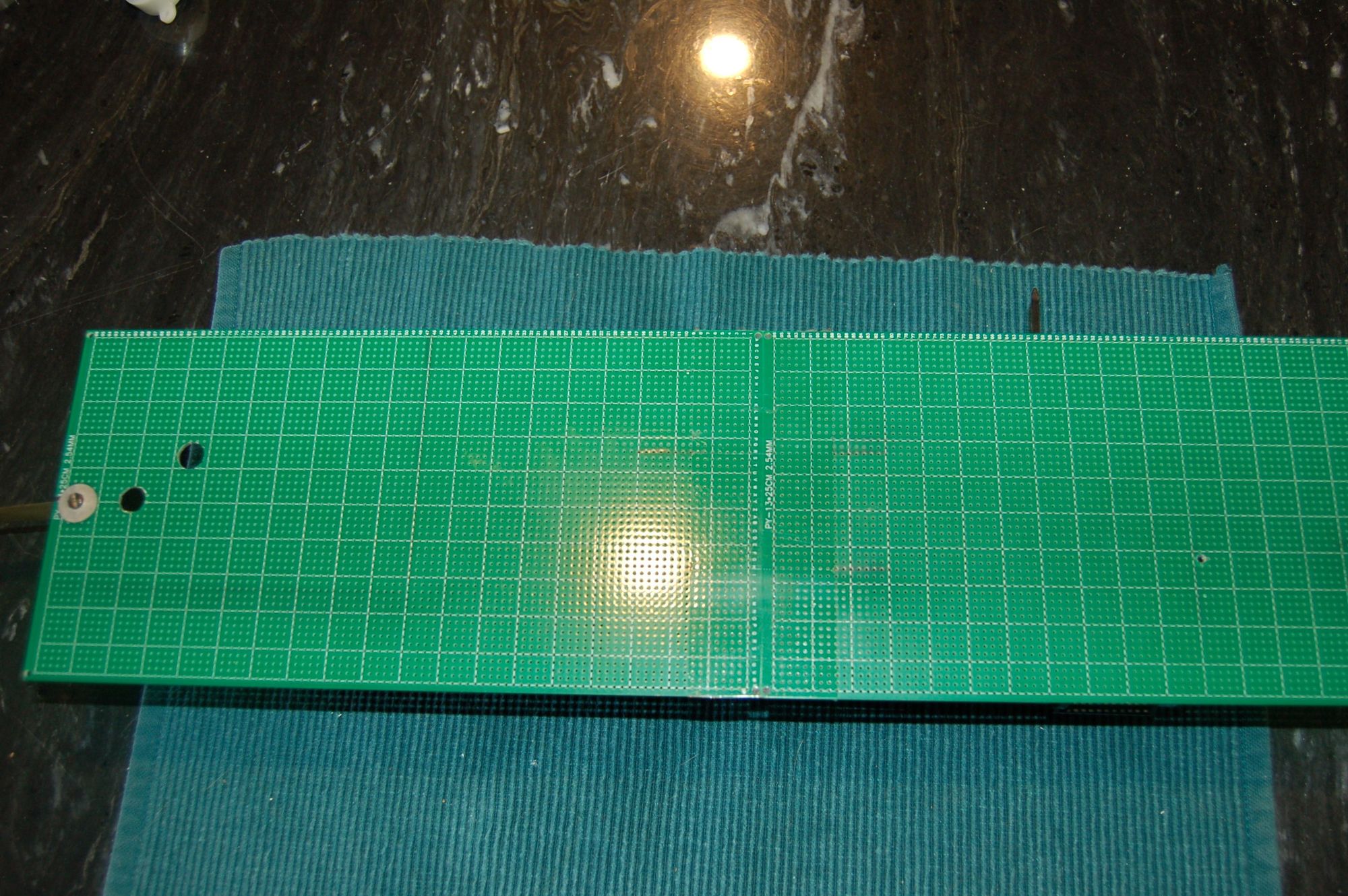

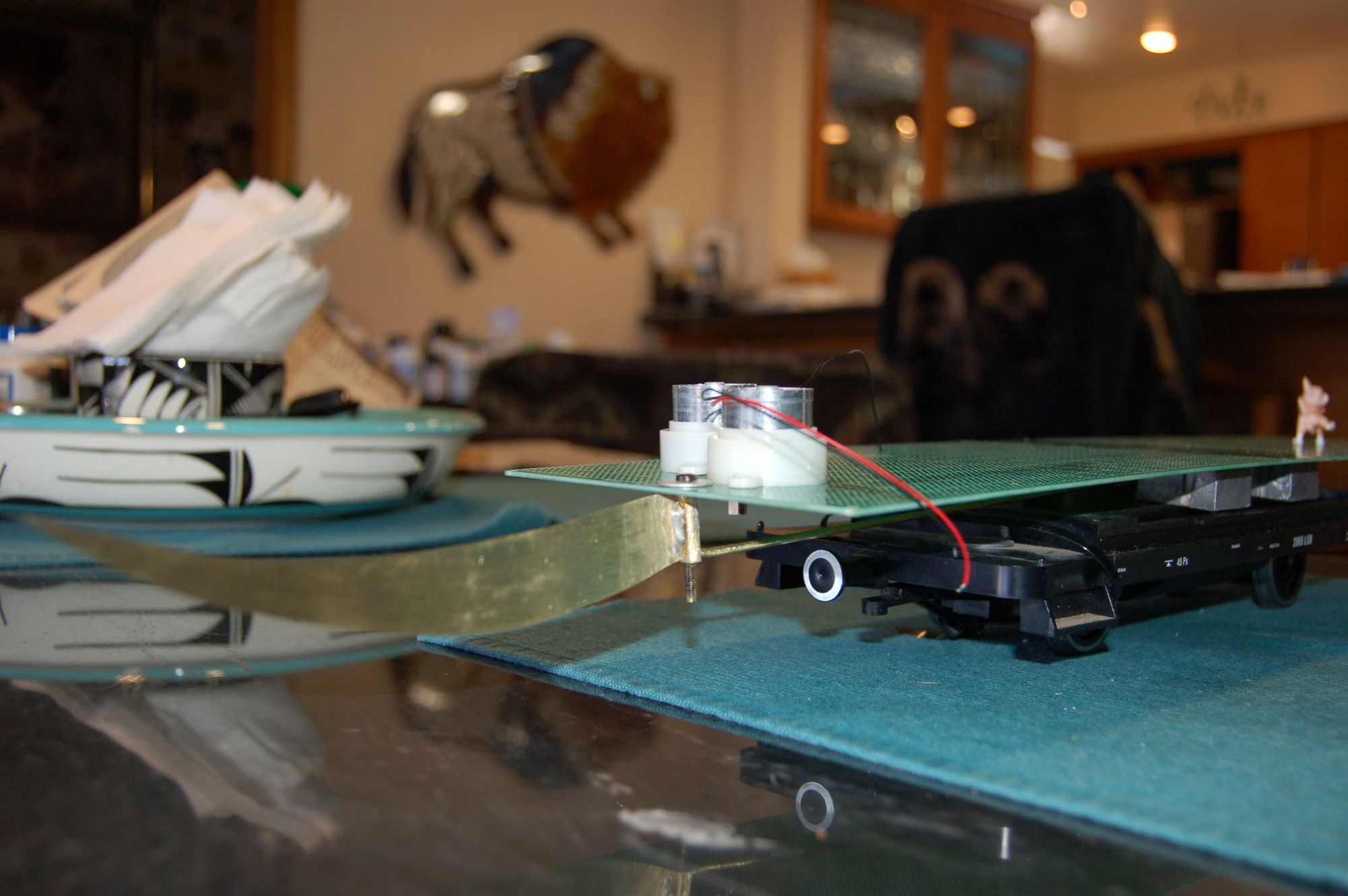

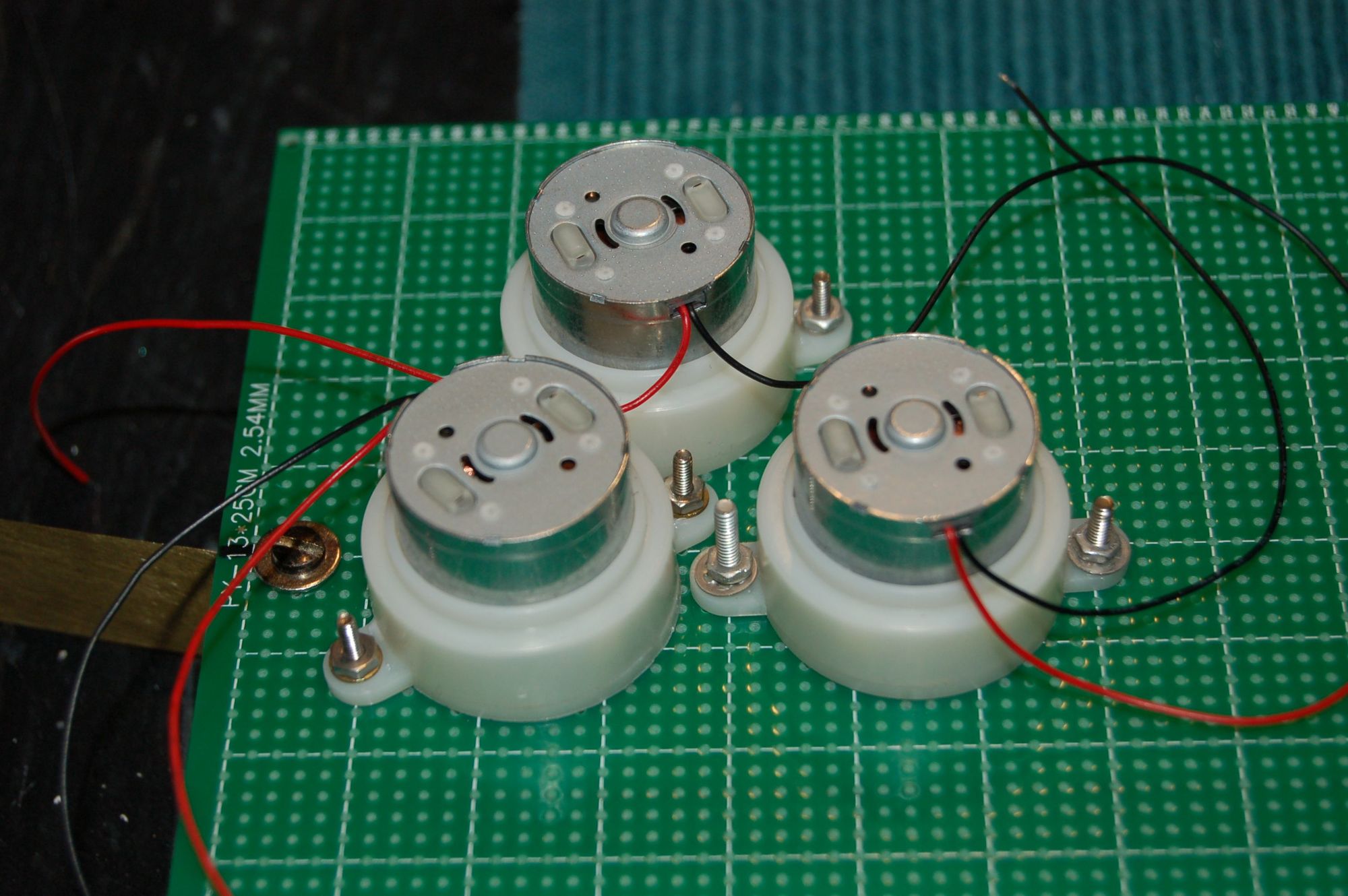

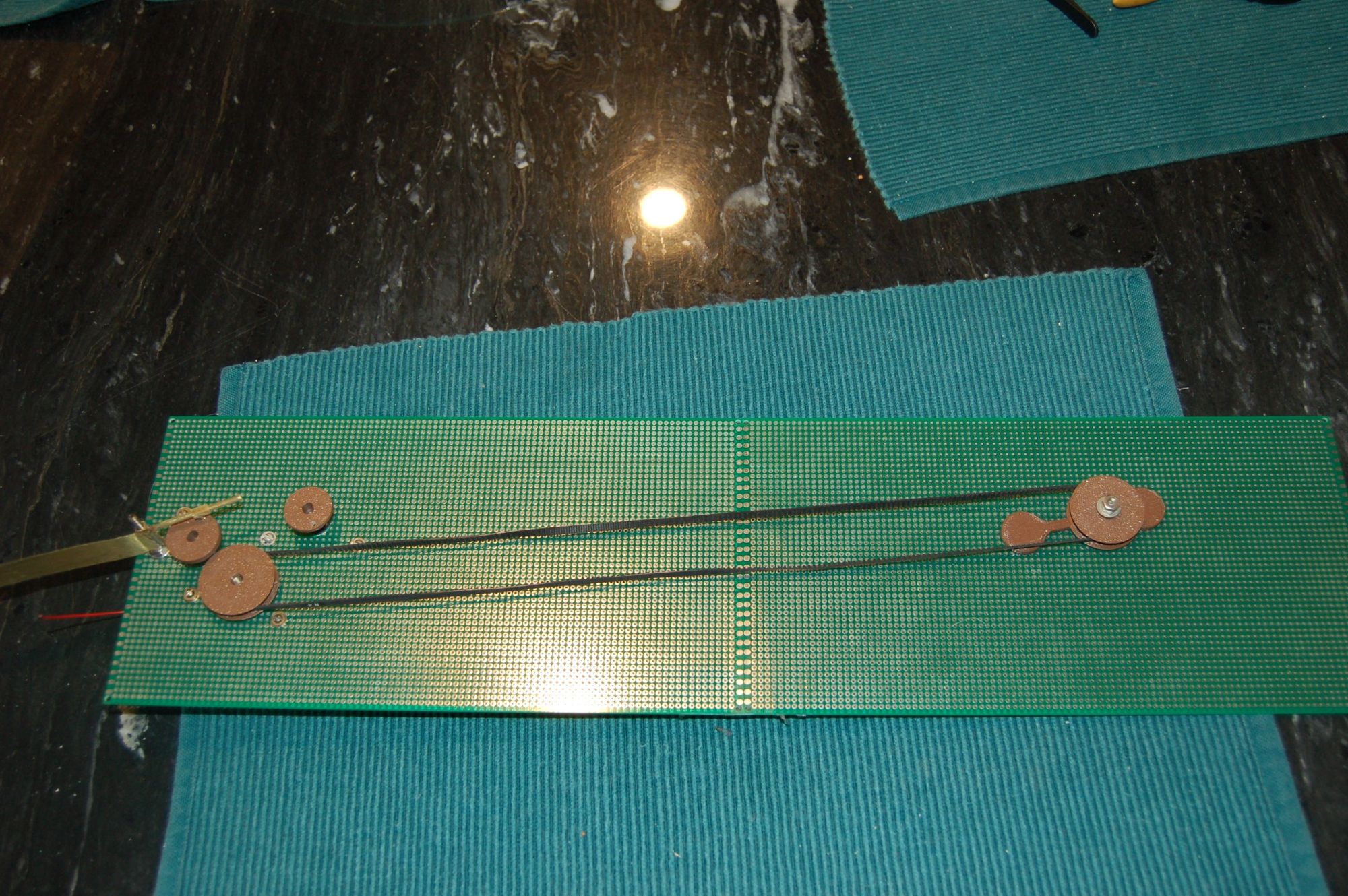

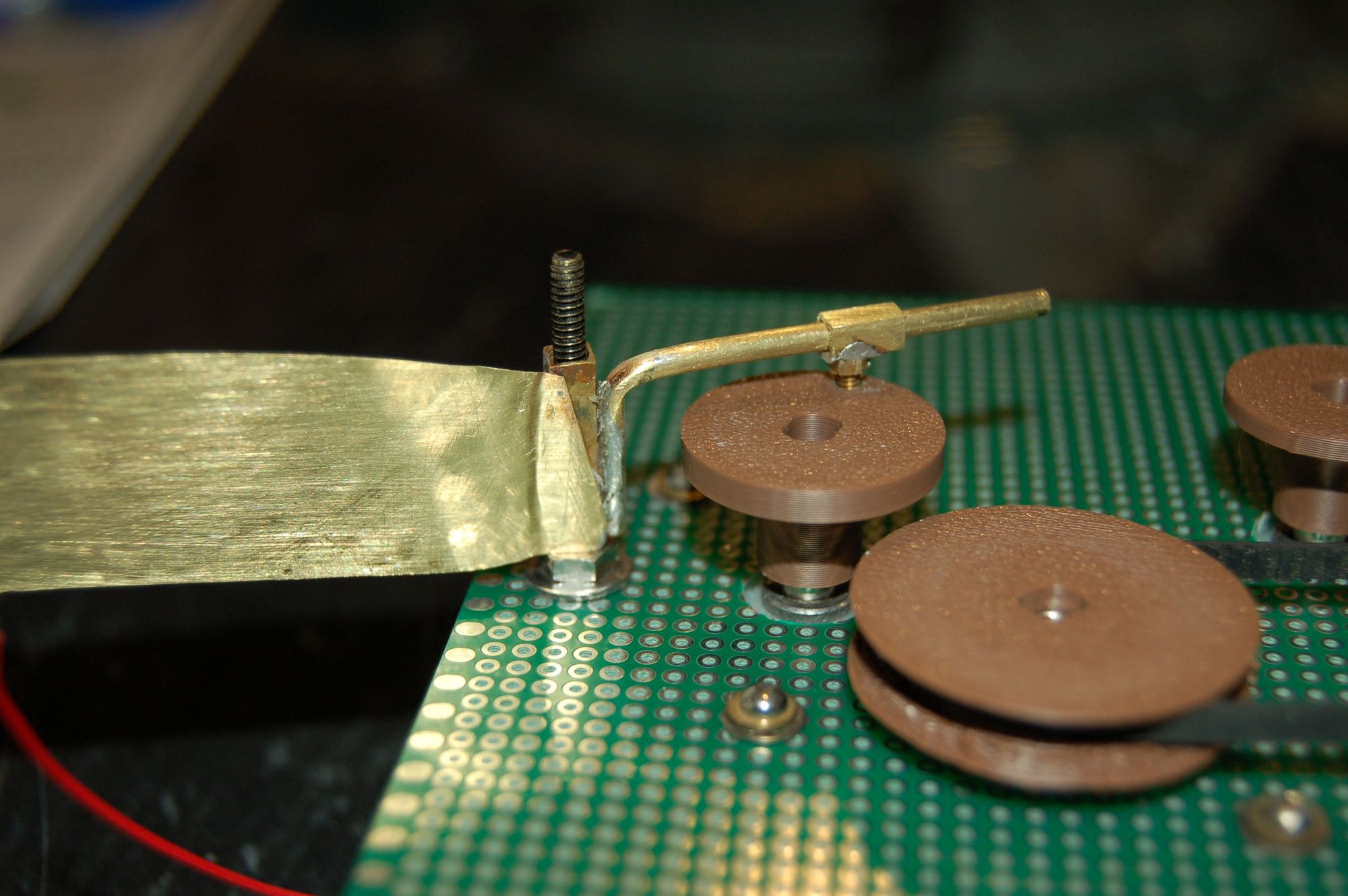

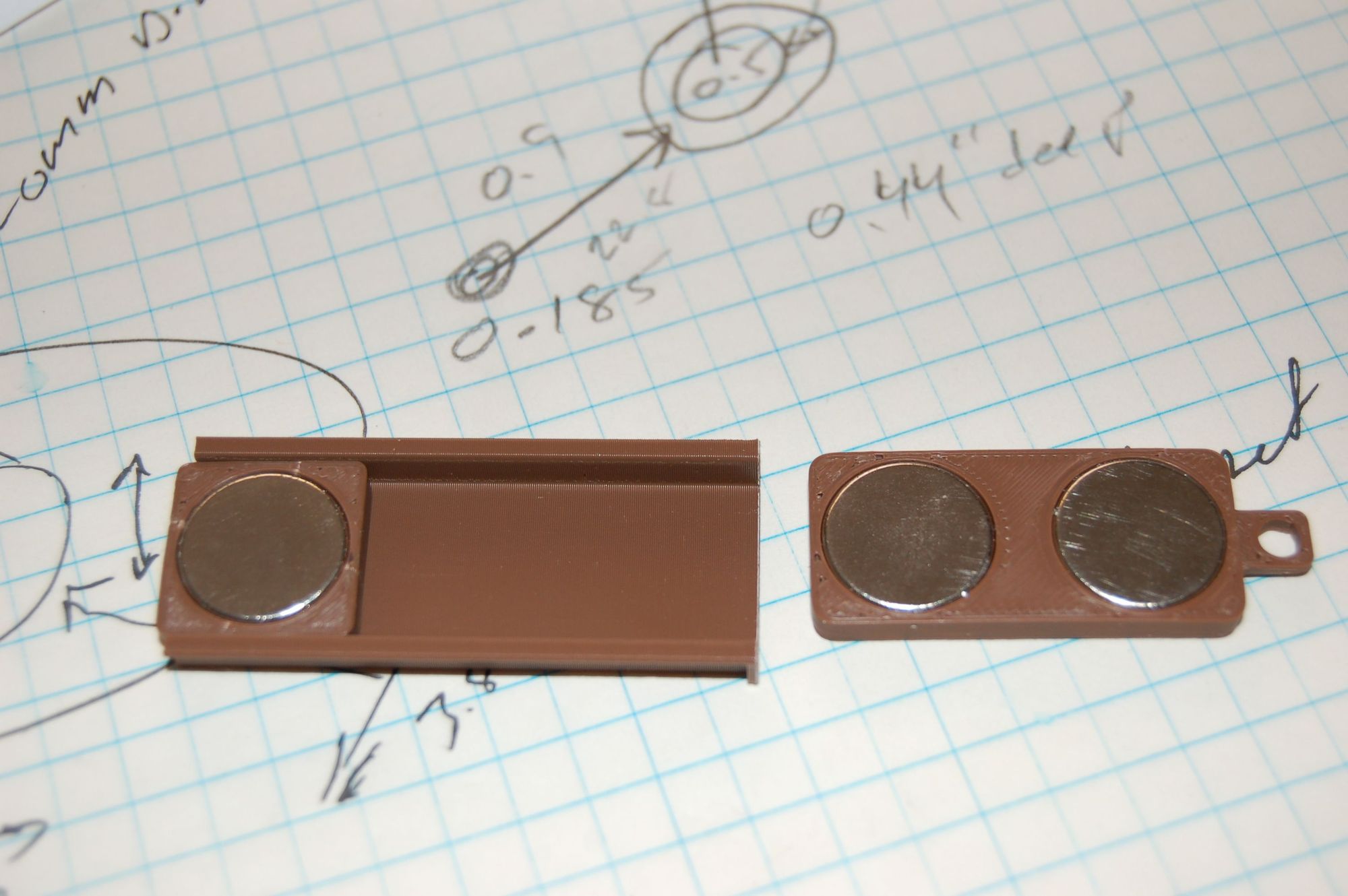

I give you the Em-Bark Dog Park. This will be based on a flat car or possibly unused LGB engine if removing the body yields a clear floor pan.

People can bring their dogs for open or covered “parking” (row of dog houses), and have them serviced while they are there. Of course we would offer valet service and for those in a real hurry “Express” packages.

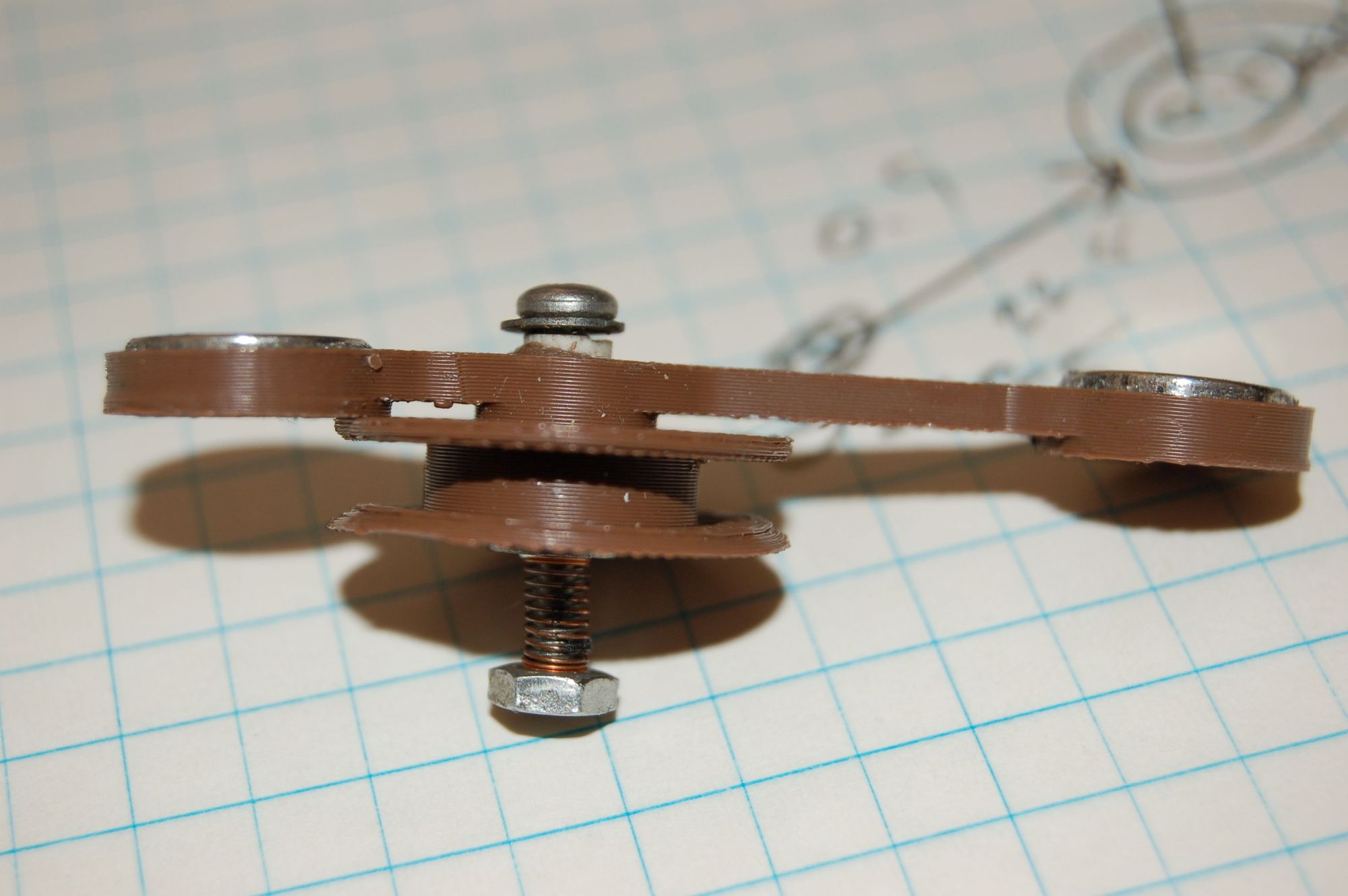

The car would be modified to resemble a dachshund and just maybe I can figure a way to make it appear to walk as it moves along the tracks.