There was a lot of talk on Saturday night about 3d printers and the like. A few suggestions came out, like a pointers/tips and tricks for the various 3d packages, and even a sticky thread with links to available files. So, what exactly should we start threads about?

Pros and cons of various machines and filaments. Ease of use with both machine and associated skills (programs and software necessary to accomplish a project). Size limitations and operating cost.

even a thread on a project from start to finish including the processes needed to achieve it.

Yes I know there are youtube videos and self help sites in abundance, but info put together by known individuals goes a long way.

The above points answer questions that arise every time I see a thread on the new technologies.(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

Just MTCYMMV

Bob,

Most hobby folks have FDM machines, Cliff and myself have SLA machines, and then the metal variants are not to likely to be on anyone’s desktop soon (tech is getting better.)

So might have category’s for them and maybe a third for commercial services like Shapeways. that way the discussion’s are broken down by type of printer. I thing having links to files that folks are willing to share a great idea, as long as the scale is listed. I find many desirable objects out there but the scale of the object is not often given, and my ability to make a measurable solid is often limited by the size of the file. might need to list what type of printer was designed for, as you can always s go to a better printer, but if the part design was for highly detailed SLA machine will not necessarily reproduce the detail in a FDM machine.

AL P.

A good start would be to discuss the differences between resin and FDM (filament) printers and the role each can play in our modeling repertoire. Both technologies have limitations and advantages.

Another idea would be to have a dedicated thread for questions about 3D printing but Have answers in a separate thread and a link by the question to the answer. I suggest this so that one thread doesn’t get so cluttered that it’s difficult to find the answers you may be interested in. I would even volunteer to maintain the question thread to keep all the questions posted in the first post and add the links to the answer thread

As I know nothing about them, I’d like to have forum/folks start with a

““Basic’s for Dummies”” of each type machine and its functions… I get

nothing from trying to learn from a technical manual… Makes me fall

asleep… (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

Cool thread! And as Al and Dan said, the process drives the discussion. FDM (“toothpaste” printing), vs resin, big differentiators… But let’s start even higher, to let everyone into the discussion, or at least see how it can relate. So, fwiw, here’s a few thoughts. I’m no pro at this, but just feel like making a bullet list.

- Types of modeling

- Manual

- (n number of methods)- Automated (or blend of automated / manual)

- Additive (3D printing)

- FDM (filament deposition, aka “toothpaste”, where you lay down a thread of material with each layer)

- SLA (resin, where either lasers or led’s harden each layer as the thing gets built)

- Others (e.g., metal, like Al points out; lotsa new tech constantly emerging…)- Subtractive

- Laser (just cut the damn sheet, and save all that money using cheap sheet stock to begin with)

- CNC routing (cut sheet stock with depth, and make 3D stuff with a flat back)

- 5-axis routing (true 3D machining, used for boats, cars, big stuff… I’m waiting for that to become desktop and under $300! (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif))- Formative

- CNC forming of sheet stock over a tool I’m making this up (but it probably exist because I did)(naah, it requires a tool made by one of the above)

OK, my list belt just ran out of bullets.

Andy Clarke said:

As I know nothing about them, I’d like to have forum/folks start with a

““Basic’s for Dummies”” of each type machine and its functions… I get

nothing from trying to learn from a technical manual… Makes me fall

asleep… (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

If this is what you are after dad it won’t work because it would still be inside you’re skull.

https://www.instructables.com/3D-print-your-own-brain/

Besides what doesn’t make you fall asleep at your age anymore!

Cliff Jennings said:

Cool thread! And as Al and Dan said, the process drives the discussion. FDM (“toothpaste” printing), vs resin, big differentiators… But let’s start even higher, to let everyone into the discussion, or at least see how it can relate. So, fwiw, here’s a few thoughts. I’m no pro at this, but just feel like making a bullet list.

- Types of modeling

- Manual

- (n number of methods)- Automated (or blend of automated / manual)

- Additive (3D printing)

- FDM (filament deposition, aka “toothpaste”, where you lay down a thread of material with each layer)

- SLA (resin, where either lasers or led’s harden each layer as the thing gets built)

- Others (e.g., metal, like Al points out; lotsa new tech constantly emerging…)- Subtractive

- Laser (just cut the damn sheet, and save all that money using cheap sheet stock to begin with)

- CNC routing (cut sheet stock with depth, and make 3D stuff with a flat back)

- 5-axis routing (true 3D machining, used for boats, cars, big stuff… I’m waiting for that to become desktop and under $300! (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif))- Formative

- CNC forming of sheet stock over a tool I’m making this up (but it probably exist because I did)(naah, it requires a tool made by one of the above)

OK, my list belt just ran out of bullets.

- Modeling Software

- Fusion 360

- Solidworks

- Sketchup

- TinkerCAD

- Blender

- FreeCad

- OpenSCAD

- OnShape

I’m sure there are others. Now, the modeling or designing may not be for everyone, but all 3D printing has to start with a 3d design from some source whether you design it or someone else does it.

Ive been quite happy using Fusion 360. I have also played with sketchup a bit.

With any 3d software there is a learning curve. Having 2d skills helps some but 3d is different. With 2d you basically just draw stuff with the computer, in 3d you create shapes, stretch, or rotate them, add or cut away details. It takes some getting used to. Often the order of operations is critical to success.

What is nice about Fusion is that the parts are based on a 2d sketch which is then dimensioned. Next it would be given its 3rd dimension. As you continue to work on your part you can go back and adjust dimensions as set earlier and the part is recalculated to reflect the change. Sometimes for various reasons you cannot do the change but it is very helpful when you can.

Made parts can also be joined into assemblies so you can see how stuff goes together. Even at this stage tweeks can be done on parts in the assembly which then reflect back to the base parts.

There are plenty of how to videos to help as you work.

an Hilyer said:

- Modeling Software

- Fusion 360

- Solidworks

- Sketchup

- TinkerCAD

- Blender

- FreeCad

- OpenSCAD

- OnShape

I’m sure there are others. Now, the modeling or designing may not be for everyone, but all 3D printing has to start with a 3d design from some source whether you design it or someone else does it.

You missed DesignSpark Mechanical which I use and is really nice and free.

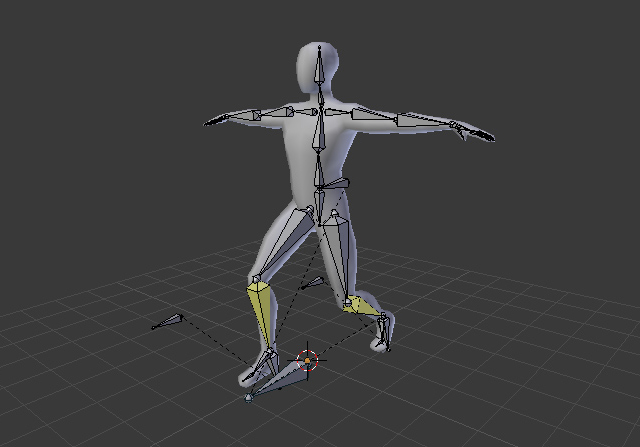

One thing I’m kind of interested in is 3D sculpting combined with posable armatures to create figures that can be printed.

I designed these in DesignSpark. I had the first one (shown) printed at the Urban Workshop and it cost me over $60. Someone on the forum then offered to print me a few more (different material in black) for the cost of shipping and the few dollars that they actually cost to make. BTW, I find the 3D printed stuff to be fragile and breaks very easily if dropped on pavement.

Jim have you looked into Blender?

Todd, I agree, DesignSpark is pretty amazing, 2D, 3D, all free, and a fairly high-end platform. I use DS circuit board design, it lets you do your boards (say, a custom board of relays and diodes, or more involved stuff), and export all the “gerber” files needed for having them printed (for super cheap).

Cliff Jennings said:

Jim have you looked into Blender?

Todd, I agree, DesignSpark is pretty amazing, 2D, 3D, all free, and a fairly high-end platform. I use DS circuit board design, it lets you do your boards (say, a custom board of relays and diodes, or more involved stuff), and export all the “gerber” files needed for having them printed (for super cheap).

Do you have any comparison between DesignSpark circuit board design and EagleCAD? I’ve used Eagle for a couple of projects but its sort of annoying to use.

I do circuitry in ExpressSCH. It is also free and they will do up circuit boards from your designs (for a cost), not that I’ve ever had them do circuit boards.

https://www.youtube.com/watch?v=wriXcNKkjNs

Todd Brody said:

I designed these in DesignSpark. I had the first one (shown) printed at the Urban Workshop and it cost me over $60. Someone on the forum then offered to print me a few more (different material in black) for the cost of shipping and the few dollars that they actually cost to make. BTW, I find the 3D printed stuff to be fragile and breaks very easily if dropped on pavement.

I remember this. Did the ones I made for you break as well? I believe they were just standard PLA.

-Dan

Dan Gilchrist said:

Todd Brody said:

I designed these in DesignSpark. I had the first one (shown) printed at the Urban Workshop and it cost me over $60. Someone on the forum then offered to print me a few more (different material in black) for the cost of shipping and the few dollars that they actually cost to make. BTW, I find the 3D printed stuff to be fragile and breaks very easily if dropped on pavement.

I remember this. Did the ones I made for you break as well? I believe they were just standard PLA.

-Dan

No, I haven’t dropped those yet. (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-innocent.gif)

Luckily, they CA back together very easily.

BTW, thanks again.

Bob McCown said:

Cliff Jennings said:

Jim have you looked into Blender?

Todd, I agree, DesignSpark is pretty amazing, 2D, 3D, all free, and a fairly high-end platform. I use DS circuit board design, it lets you do your boards (say, a custom board of relays and diodes, or more involved stuff), and export all the “gerber” files needed for having them printed (for super cheap).

Do you have any comparison between DesignSpark circuit board design and EagleCAD? I’ve used Eagle for a couple of projects but its sort of annoying to use.

I’m afraid I don’t Bob, other than vaguely remembering comparing them and deciding on DS. My dealmaker was that DS imports dxf (I start in Autocad for the board shape and main components), and exports in gerber (can’t remember if EC only exports in a proprietary format).

Cliff:

Yup, I have blender. I even bought a tablet. The thing I’m short on is time to learn how to do the armatures and the sculpting…

Jim, if you are interested in figures, get MakeHuman. It exports a blender format called mhx2. You can do a simple character, add bones and a basic pose, then pull it into blender to tweak. Much quicker than trying to model something from scratch.