TGIF. Working a few late evenings during the week ensures an early out on Friday as we have a no overtime policy at work. Today I was able to finally get started on the corner stabilization, work on the the lighting and install a few replacement boards. I also cut and stained new trim boards for both ends to continue the horizontal detail fully around the building. Now I’ve got some type of doors in my head as a winter project.

The acrylic for the corners / end walls was glued in. I didn’t have much luck with the water thin stuff as the cut edges were not smooth enough to bond. I ended up using the medium body acrylic cement in just the fillet…

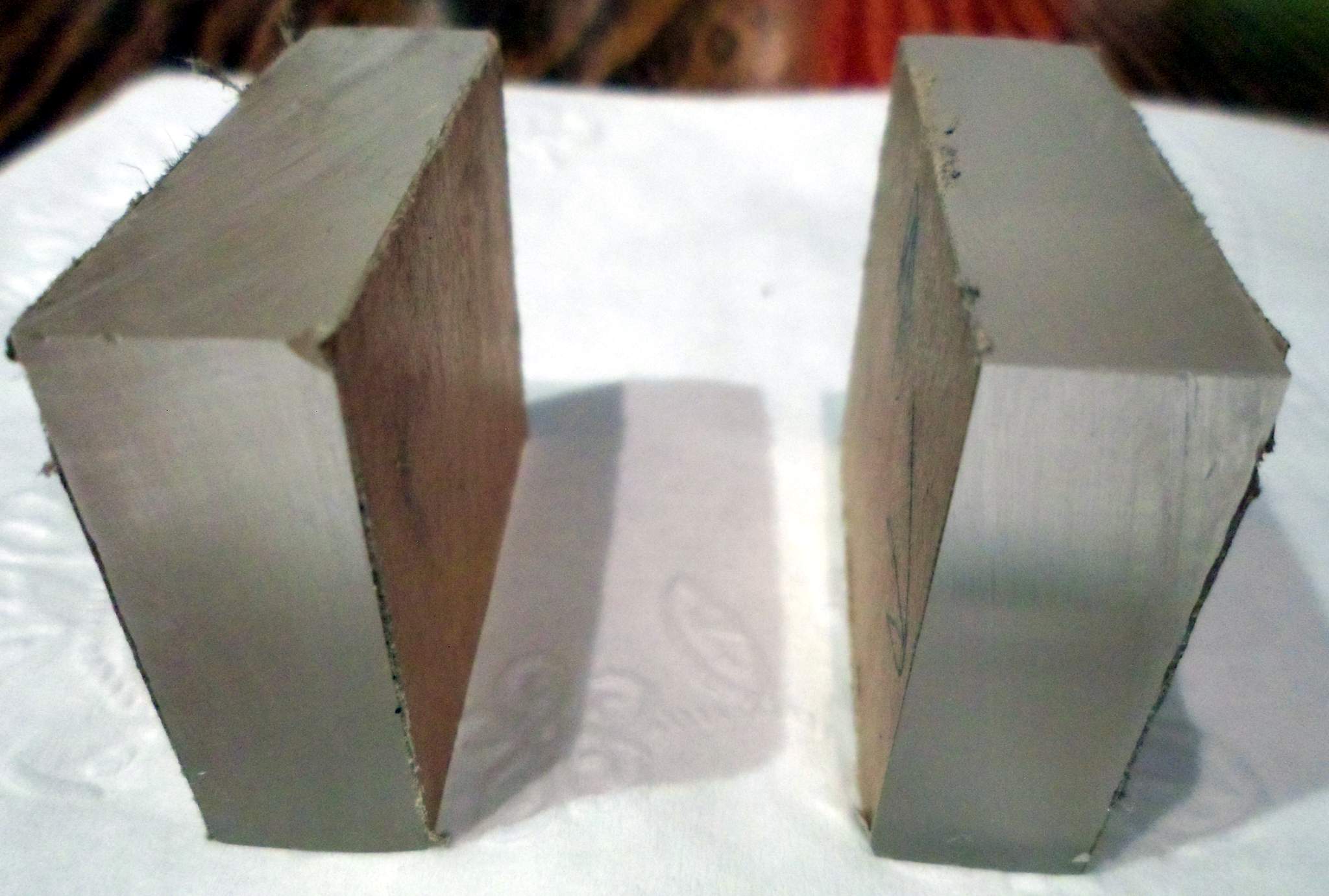

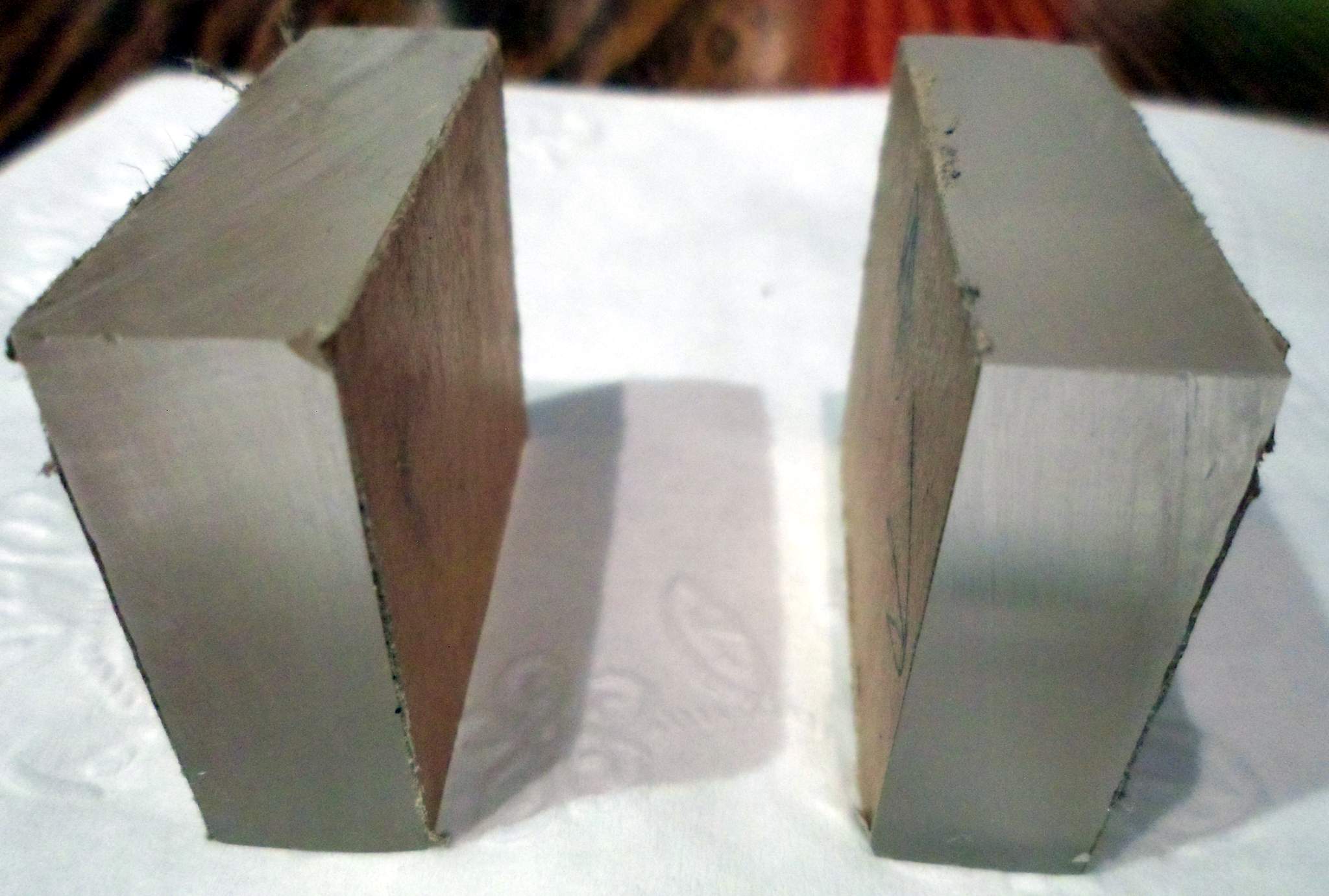

The pieces above and some 1/2" thick corner blocks were cut a few weeks ago in my work shop. Today I needed to trim .25" off one side to fit the corner in the above picture. This time I sanded the edges to be glued to 600 grit. In this photo the block on the left has a raw edge on top. All the other edges in the shot have been sanded…

These blocks will be glued into the corner near ground level. Eventually they will be drilled to line up with Tapcon screws to be put in the building’s foundation. That might be a Spring '18 project.

Next I worked on the lighting. The LED strip had been fabricated quite a while ago waiting for permanent install. We’ve never had a discussion about cross-posting here on LSC. So rather than cross post a bunch of pics, I’ll put all the detail pics in my Lighting Thread tonight. This is the finished install. LEDs point up…

I didn’t take pictures of the repair pieces installed. There were just a few pieces of siding around the windows and one board on the vent. At this point the building as it originally existed has been restored as much as it will be this year. After dark I worked on color reflector panels for the inside of the roof and cut up and stained all the pieces necessary to add trim to the ends…

There is only one good weather day this weekend and I have a lot on my to-do list. I hope to get an hour or so to put in and maybe get it back on the foundation.