A picture says 1,000 words…

Thank you !

A picture says 1,000 words…

Thank you !

Nice roof line! Drastic Plastic should be a rock and roll or punk band name.

A couple of shots of the kiln lumber carts with the plastic wheels that disturb Rooster so much, hmmmm, I think I will try to find some more of these plastic wheel sets and post pictures of them(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-foot-in-mouth.gif)

Thanks for looking.

Rick,

I would like to add a side note to this thread…Eric Mueller clearly is following along and owns about 1/4 of my plastic wheel sets. If you want the other 3/4 that I have it’s all yours. But I’m thrilled that he’s watching your thread!

Someday I will convert you both to really cool stuff like Amtrak!

(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

Rooster said:

…Eric Mueller clearly is following along and owns about 1/4 of my plastic wheel sets. If you want the other 3/4 that I have it’s all yours…

Fear not! They shall go into yet another project! Maybe an Isle-Trak MOW train…

Rooster, thank you for your generous offer of the wheel sets but they would be much better off rehomed elsewhere. As far as Amtrak conversion(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-surprised.gif), that ain’t gonna happen(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-smile.gif)

Rick Marty said:

Rooster, thank you for your generous offer of the wheel sets but they would be much better off rehomed elsewhere. As far as Amtrak conversion(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-surprised.gif), that ain’t gonna happen(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-smile.gif)

![]()

Rick,

You don’t know unless you ask!

For today’s exciting installment we have the Kiln building and loading shed set in place on the mill diorama.

Good morning.

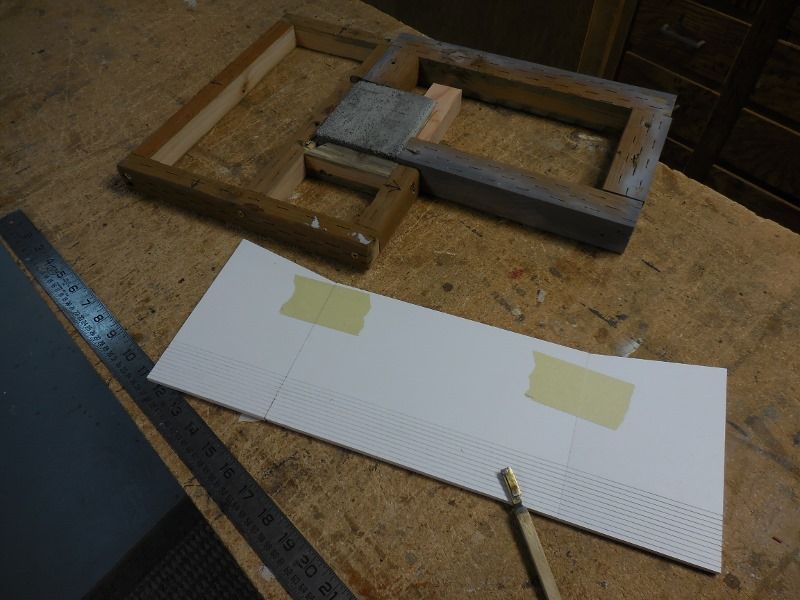

Here is the start of the boiler house for the dry kiln. I wanted this structure to look like it was added onto several different times so used some different types of construcrion materials.

The foundation platform with the concrete deck in front of the boiler. The 3 sides of the boiler room with the brick pattern being scribed into the PVC (Sintra) sheet.

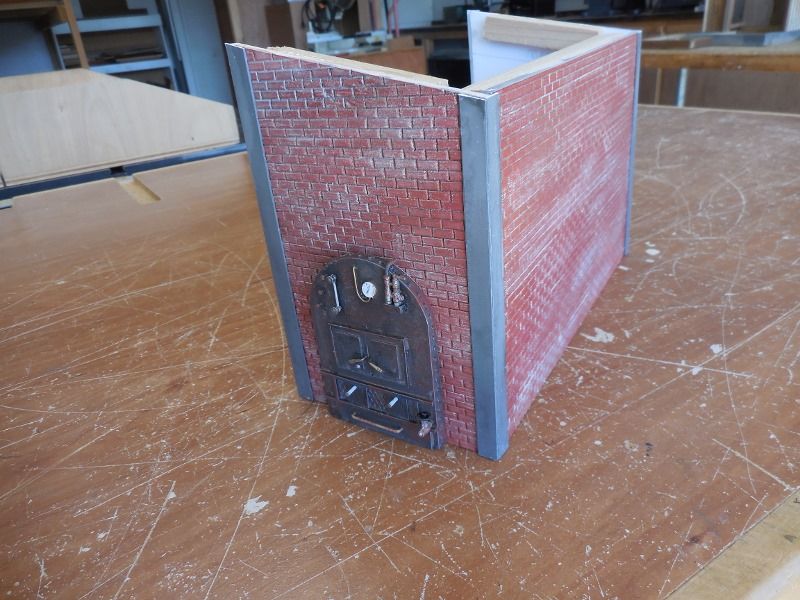

The boiler room walls and boiler front finished.

The wood walls for the equipment room side of the structure made from new and used Western Red Cedar.

From the other side.

That’s all for now.

That door/control panel in the brick wall seems worthy of a closeup shot! Nice work as usual, Rick…

Thanks Jim,

The boiler front was scratched from Styrene and junk and made to resemble a generic wood fired boiler. I think some closer pictures may show up pretty soon(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-smile.gif)

Rick,

Where you do you find/buy your PVC board?

Craig

Hi Craig,

The last sheet i bought was about 2 years ago. About 100 bucks for a 4X8 by 1/4 inch. I got it through a local glass shop in Medford, OR. You can find it on line a little cheaper but it has to be cut down to smaller sizes to make it shipable.

I’ve got a semi local plastic supply house that I use for styrene. Maybe they also stock PVC? Last time I looked a 4x8 sheet was around $150-200. I’ve got a scale 60x60x30 brick building on my near future build list and I’m debating if I want to go the hand carve route. Or take advantage of the laser cutter at the school I work at. The shop teacher told me I he can cut acrylic as long as I supply the drawing. Knowing my level of CAD skills ( beginning) it might take just as long as hand carving!

Well here is the finish of the kiln boiler shed.

I decided to lay the Redwood decking at a 45 degree angle just for visual interest.

Finished and set in place, I hope the different wall and roof finishes give it that added onto look as the years past.

The small shed like structure between the kiln building and the boiler building is to house the pipes that carry the hot water to and from the coils in the kiln building where the fans push the air across the hot coils and through the lumber stacks and carry away the lumbers moisture.

The fuel storage area where the block car delivers the mill slabs to be stacked and stored for use in the boiler.

On to the next project.

Why is there an angled unloading area on this? I love the variation in materials and how you laid in the wood siding and decking, particularly the 45 degree decking. Sweet!

Jim,

The mill blocks are delivered in a side dump car with doors that lift up. In theory the angled planks go in just under the edge of the car and the blocks spill onto the deck instead of all over the tracks. If this were a 1 to 1 situation i’m sure that theory would be worthless. I’ll see about a picture.

Here is the block car at the boiler house showing how the mill blocks will dump out onto the platform to be hand stacked. There will be a siding at the main sawmill building and a chute where the scrap blocks will dump into the car. This one car creates some good operations, when full it is pulled out of the siding and pushed down the spur to the boiler house. After one side dumps the car and engine pull back up the spur and take the side to the turntable. Once turned the car is taken back to the boiler house to finish the dump then returned to the mill building siding.

I got this car from Dick Smith, this is the one that had the weird undersized trucks and wheels that I talked about earlier in the thread where I used the wheels for the lumber carts at the kiln. The car is hand built looks like a craftsman type kit similar to a Hartford or maybe a Simpson offering from long ago. Dick didn’t have any information on it as it came to him as a gift from an estate, kind of a mystery car.

Whatever the case it was/is just to nice a car to toss so I fixed it up, put on some Delton classic arch bars and Sierra wheels and invented a purpose for using it. Oh ya, it scales out 22ft by 7ft in 1:20 scale, small but fine for a mill yard car.

This about wraps up the kiln/boiler house phase, on to the next project for the mill.

And I’m guessing “mill blocks” is another word for Firewood?

Ken Brunt said:

And I’m guessing “mill blocks” is another word for Firewood?

Yes it is, sorta, The log edgings can be cut to any length in the mill. The length would depend on what the wood was going to be used for. Locomotive and other boilers usually 2-3 feet long, stove wood was 16 inches long. As a kid living in the sawmill camps everybody burnt the mill blocks or edgings because they were free, the down side was the wood was wet and unless you kept a really hot fire all you got was a smoky, no heat, smudgy sorta fire.