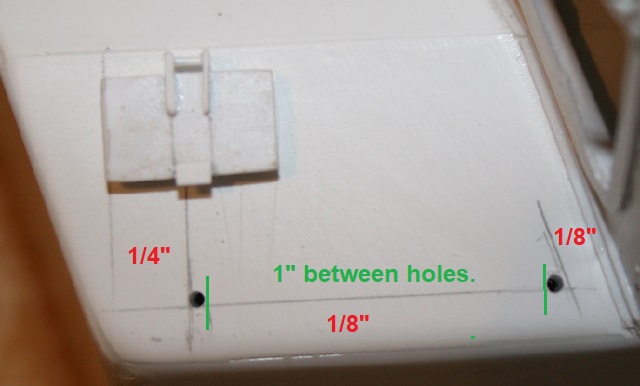

The side nose grab irons sit 1/8" from the sides and rear. The front is 1/4" back from the line you drew for the sand hatch. Drill 3/64" holes within these lines. You should have 1" between the holes.

Add your grab anchors towards the center of the nose.

I made a little jig as shown below to help get the shape I was after, and to keep the shape consistent. I started at the left, bending the rod into place, and then cutting off the excess at the right.

Now bend both sides around the outside guides.

This should allow you to get a consistent look.

Mount these with about 1/16" of space between the nose and the center part of the grab iron.

x