Well, with all these great build ideas being posted I feel a little silly posting about a build as mundane as a water tower![]() , but it is what I need for the railroad so I will go ahead

, but it is what I need for the railroad so I will go ahead![]() .

.

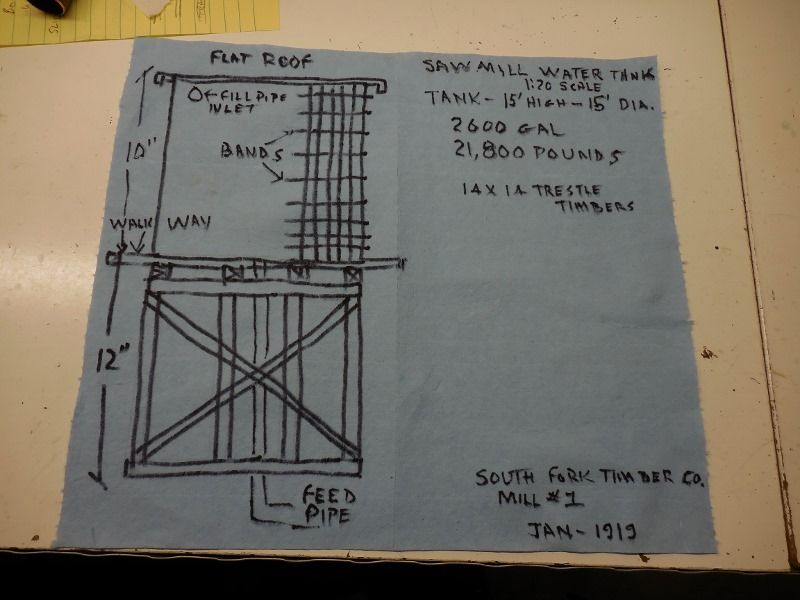

My currtent expansion for the railroad is the South Fork Timber Companies Mill #1 and associated yards. If the weather will ever give me a break I will post about this expansion in my South Fork RR thread. The idea for this water tower has been in the “one of these days” file for quite some time and with the announcement of this years Challange subject it was to perfect a fit to not jump in. This is a utility water tower not a railroad water tank.

Pictures.

Here is a photo of the mill I am basing my mill build on even though there is no railroad associated with the one in the picture there will of course be a RR for my mill![]() . The water tower I intend to build can be seen in the middle left hand side of the picture.

. The water tower I intend to build can be seen in the middle left hand side of the picture.

Napkin drawings. We have no napkins in the shop so I was forced to use Shop Towels, which, by the way, are pretty hard to write on with a Sharpie.

The “can” is one of those Christmas popcorn buckets, you know the type, we received as a gift years ago. The wife saves anything like this and several years later we painted it flat black and she used it as a plant stand extension in her wrought iron plant stands. About a year ago she no longer needed it and I set it on a shelf in the shop and waited, and look what happened![]() .

.

The chunk of old growth Redwood is from a water tank, how cool is that? The wire will be used for the bands, a little small but it is what I have, all other needed materials should be in stock.

This may turn out to be a no cost build![]()

![]()

Well that’s the plan, nothing exciting but should be a fun build anyway. Well hell arn’t they all fun?