Bob, I think I would do it the same way as you are doing it.

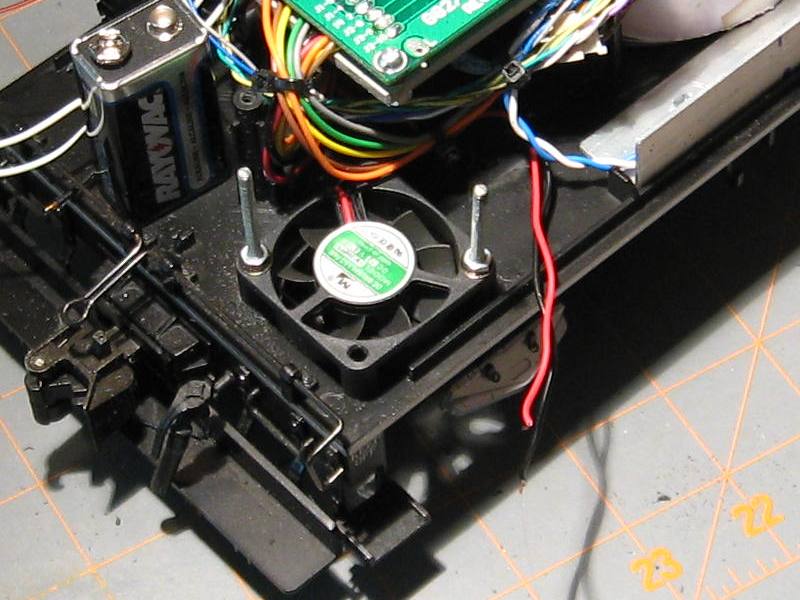

First, I have learned a bit about cooling “consumer devices” in my career, and one precept that seems to be pretty much universally accepted is that unless you are force cooling with a huge fan and ducts, don’t fight the direction of convection currents.

Those will be upwards in conditions you would encounter (outside, and sun shining on a black object).

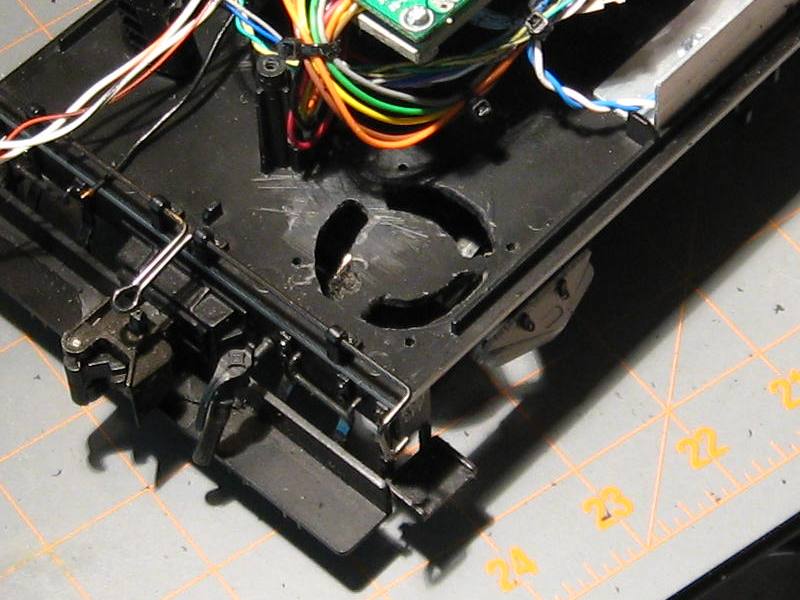

Also, on the intake side, pulling air from the underside of the tender, guarantees it will be in the shade (usually ha ha!) and thus cooler air will be pulled in.

Strategically placed “exit holes” can help also route air where you want flow.

There’s dust everywhere, and it’s not proven to me that air from 1" above the ballast is significantly more dusty than air pulled from 4" above the ballast.

Regards, Greg