Being as my electronics didn’t arrive in the mail today as they weer supposed to, I moved on to the locomotive modifications. The four major mods to be done are:

-

Lock axle #1 and #4 to near ‘0’ side play

-

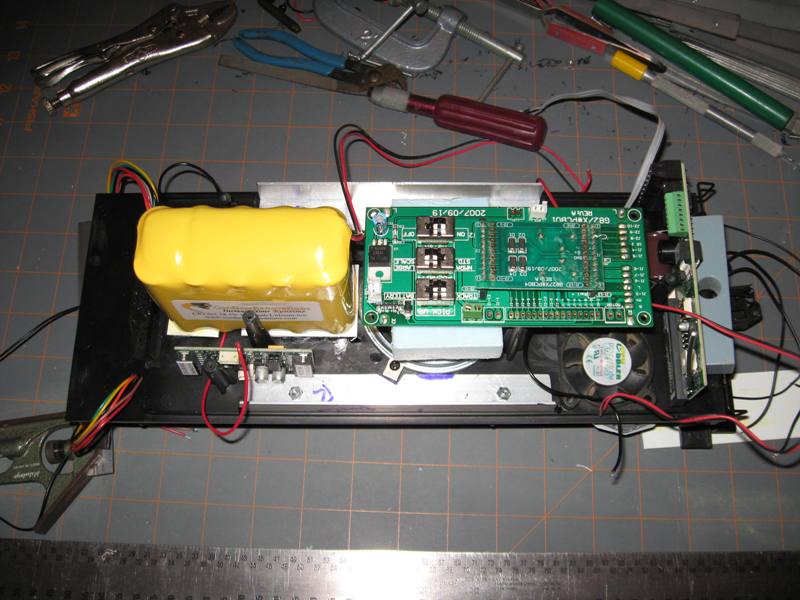

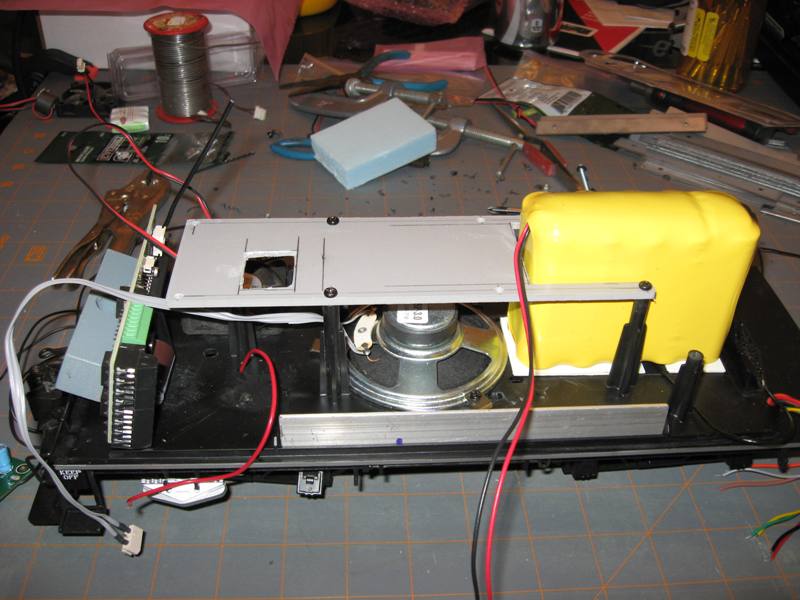

Install Rodney’s gear reduction drive

-

Remove the cooling fan (don’t think I am gonna need it)

-

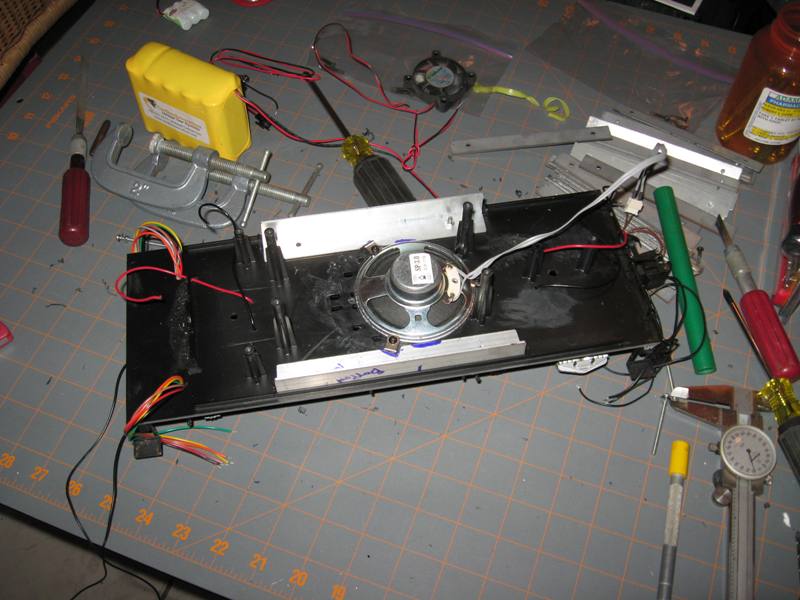

Remove the smoke unit to make way for a speaker and possibly more weight in the front.

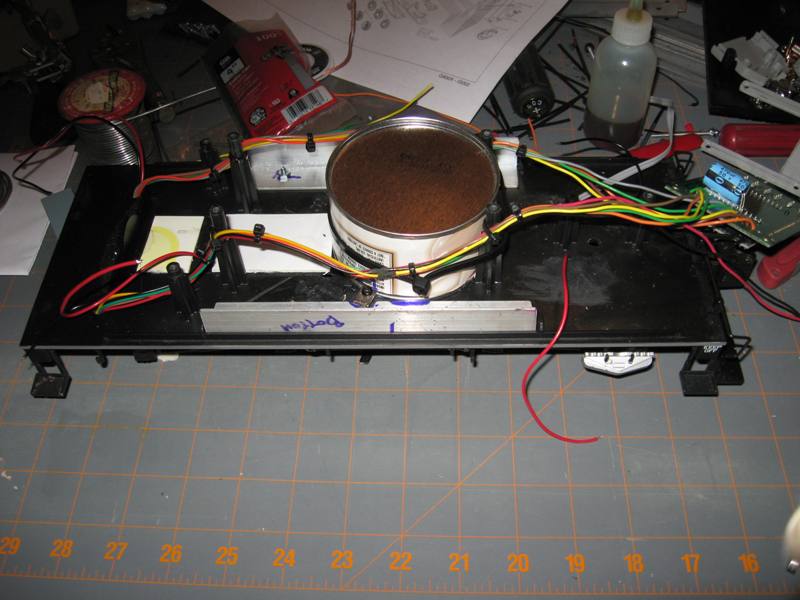

Please excuse the pictures. I got in a rush to get it done and forgot to take pictures during dis-assembly. I think the shots during re-assembly, shown backward will get the idea across and allow me to do some explanation. I borrowed a trick someone else on the forum commented about and used the original styrofoam packaging as a work stand.

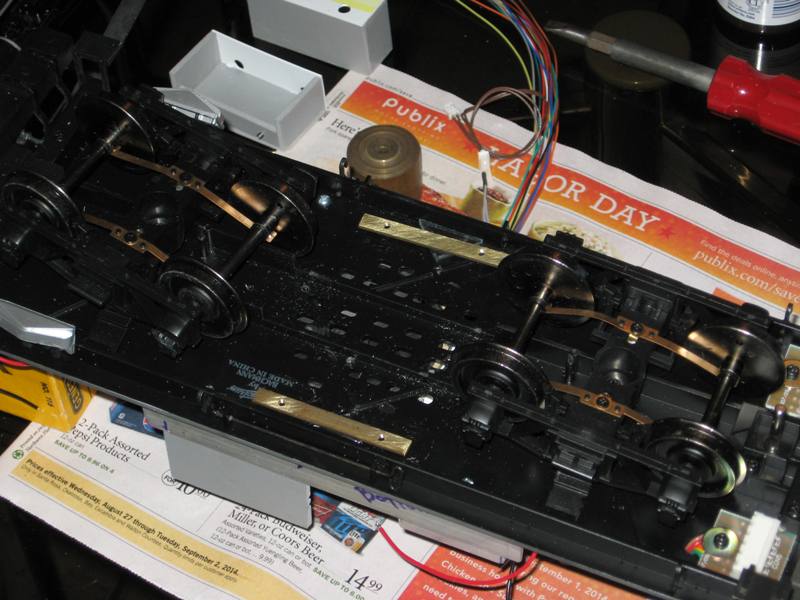

First task is to remove the retaining plates holding the journals in place. As I started to dis-assemble these I notices that several of the screws were no longer tight, but has begun to loosen and work their way out. Note to self, check these screws periodically.There are 5 screws in the front retainer and 4 in the rear retainer.

Next task is to carefully pick up and remove the brake rigging that goes down the center of the locomotive. The front rigging will have the brakes for axles 1, 2 and 3. The rear rigging will cover axle 4, and there will be a single screw holding it in place, centered on the rear of the rigging.

Once the brake rigging is removed and out of the way, remove the screws the attach the rods to the counterweights. These are a 9/32" wrench of socket. You will need to rotate the drive about 1/4 turn to be able to remove the screws side to side. Once removed you will be able slide the rods off the counterweight and be able to lift the axle out of the frame. Do this SLOWLY to make sure the suspension springs and electrical pickup springs (located inboard) remain in their locations. I recommend doing one axle at a time to assure parts don’t get crossed up.

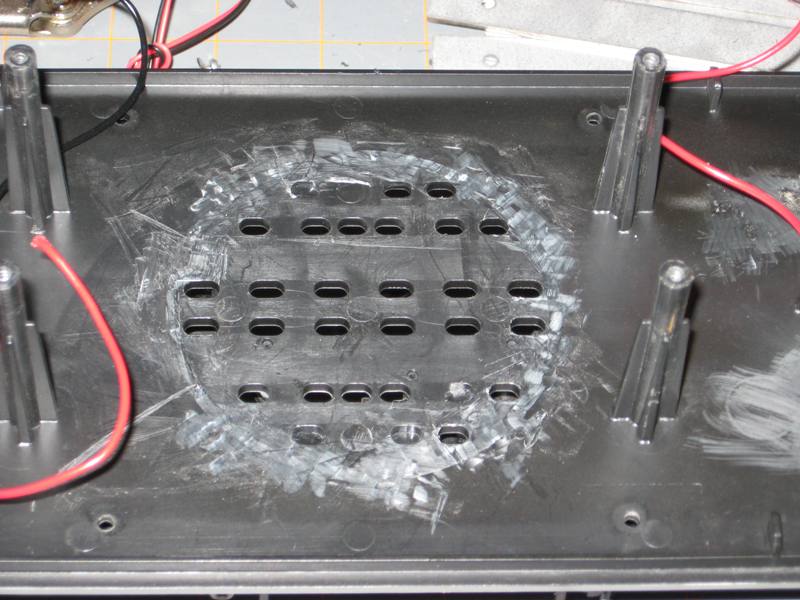

In the photo below, I show the 4 springs that make up the suspension for each axle. Two important items to note. 1) According to TOC (Curmudgeon) all four springs are required to make the suspension work properly, so even if you don’t use track power keep these in place. 2) Just like all the other moving parts of the locomotive, lubricate these periodically.

While I had my loco open for surgery, I removed one of the suspension springs under a journal and did some measurements. For those interested, the spring is 0.103" OD, 0.320" free length, and .013" wire diameter. I have found some slightly heavier springs from Century Spring Co. that I think will work to remove the ‘butt drag’ so many notice. I went to order them online, but they require a $40.00 minimum order so that didn’t happen today. I do have a plan…

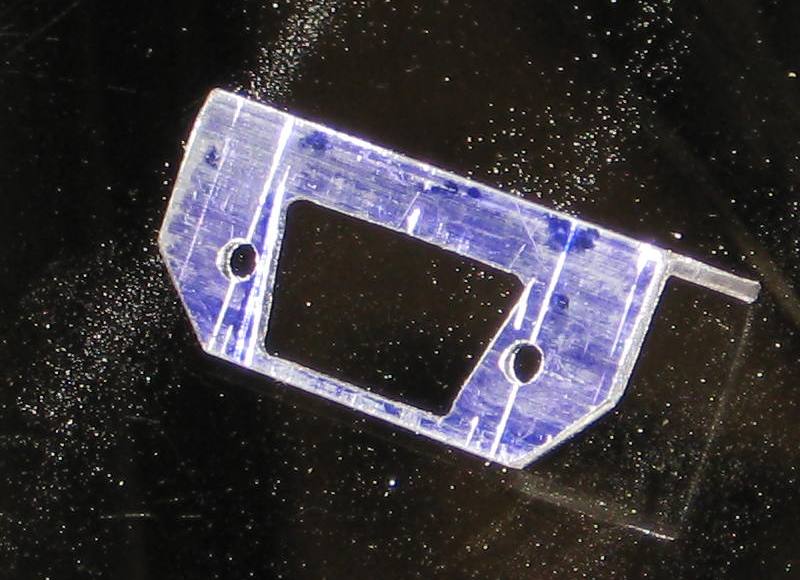

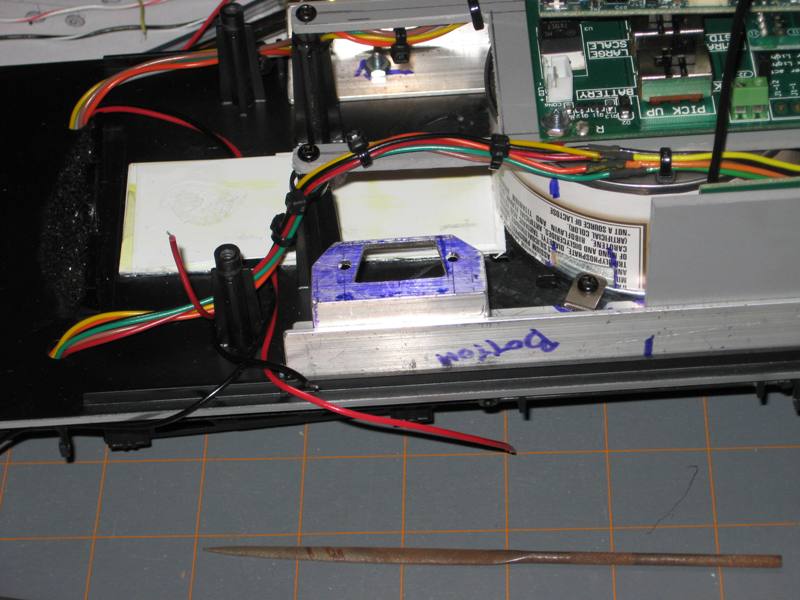

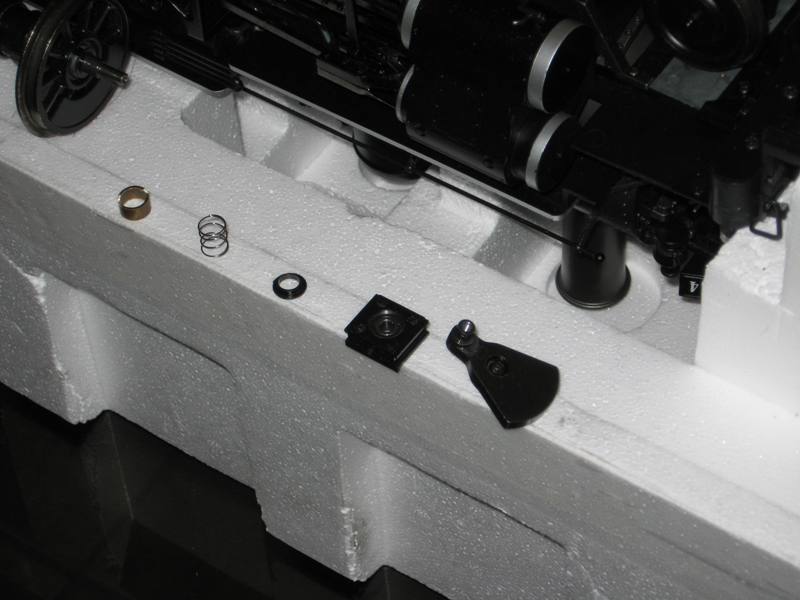

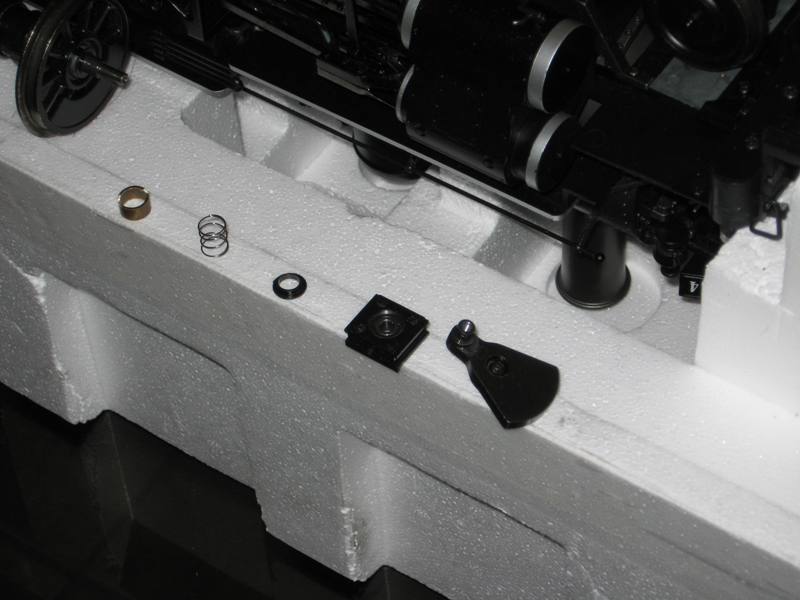

The spacers I made for my K are from a piece of tubing I had in my brass bits box, .375" OD x .250" ID. After a couple of false starts I ended up cuting .200" LG (+/- the thickness of my razor saw) and came out with just about ‘0’ side play. The picture below shows the ‘exploded’ axle on one end. From left to right - axle, new spacer, OEM spring, plastic collar, journal/bearing, and conter weight. Do what you will with the spring, removal is the purpose of the exercise. First install the spacer, followed by the plastic collar. Here is where the ID of the tube is important. The collar fits perfectly inside the .250" ID tube. Follow this with the Journal/bearing and lastly the counter weight. There is a loose fit between the axle and the electrical pick up segments. Keep this loose fit. If the fit is too tight it will make the engine ‘waddle’.

Re-assembly is the opposite of the dis-assembly with the following caveat. The is a small ‘tit’ on the top of the journal/bearing that fits into the center of the spring. Be sure of the orientation of the journal/bearing when re-installing it into the frame so the journal/bearing is located properly.

The length of the spacer I provided is for reference only as this is what fit my K27. You may need to adjust this a bit for yours.

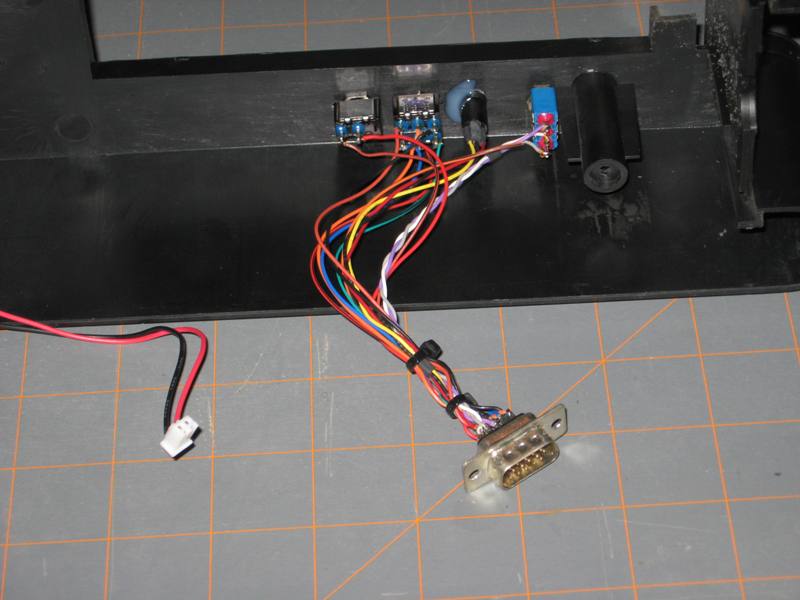

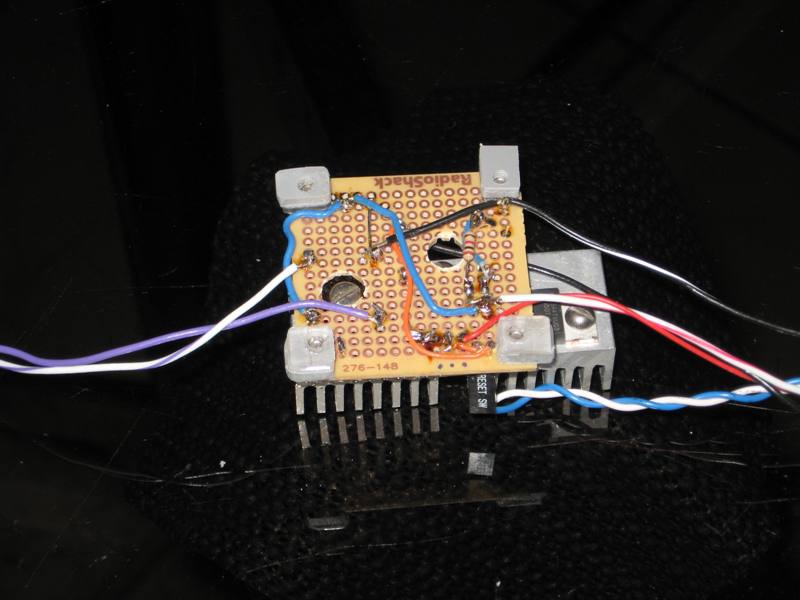

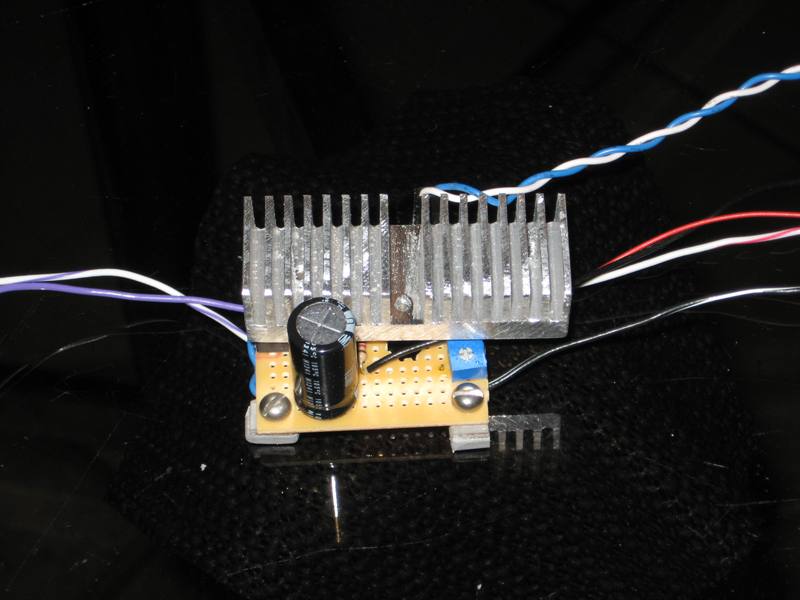

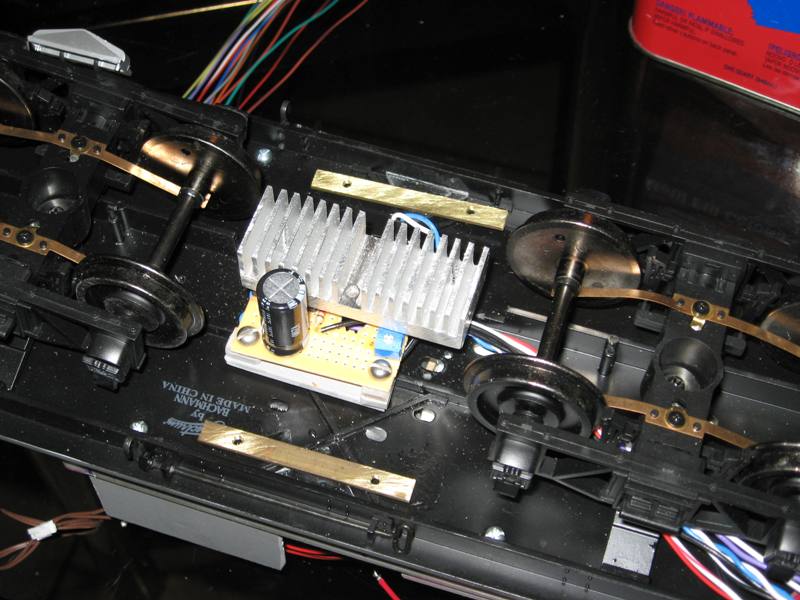

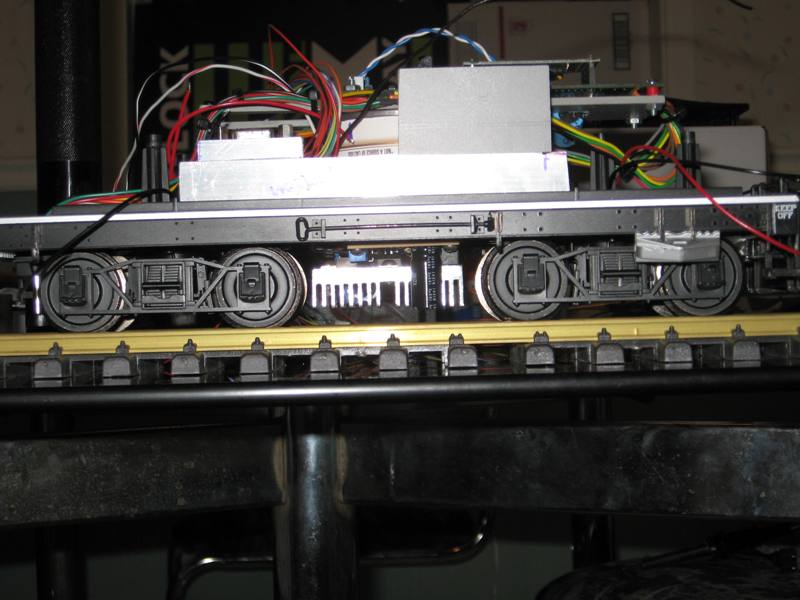

I didn’t bother to photograph the installation of Rodney’s drive as I seem to remember he had an instruction sheet on he web site. Removing the fan and smoke unit are sort of a no brainer. The only thing I did on the smoke unit was to slip some heat shrink over the eye connections on the ends of the power leads.