I followed Fr. Fred’s advice and ground off the plastic guard rails on the Aristo wide radius switches, replacing them with brass guard rails set at the correct gauge.

Lynn Wescott’s Rule of S Curves applies to turnouts, too.

I followed Fr. Fred’s advice and ground off the plastic guard rails on the Aristo wide radius switches, replacing them with brass guard rails set at the correct gauge.

Lynn Wescott’s Rule of S Curves applies to turnouts, too.

Stan, what type of accucraft wheels are giving you problems? I learned a lot from Phil of Phil’s Narrowgauge about accucraft wheels when I added bearings to my AMS cars. There are a few different styles they have depending on the age of the car. I’m sure I’ll mess this up, but if I remember correctly, the oldest ones have a knife edge flange and poor wheel contour and are made of brass. The next ones are roughly the same and made of metal, the newest (and best) have a good contour and flange and are metal. I had terrible problems with the brass ones picking points and climbing rail in turns.

This still didn’t fix the aristo switch but it eliminates the crappy wheel from the equation.

Terry

Thanks Stan. I run a mix of Accucraft, Bachmann Fn3 and Aristo steel wheels. I haven’t taken notice of which wheels are the most problematic. Your fix is similar to the one of Ted’s on Greg’s site. I will try and implement your idea on one and see where it gets me.

Todd - Running mostly Accucraft couplers body mounted. I trim them a bit to allow a little more swing than stock. I have the problem on all my Aristo “Wide” switches regardless of the track configuration. One is a long straight leading into the facing points and the diverging route is straight. The one that has really brought this issue to the forefront is in the center of the large loop shown below…

The loop (part circle in center) is the main line.

I’m sure part of my problem stems from track gauge Vs. wheel gauge; especially in the above situation, because if I stand there and push the second axle of each truck toward the outside rain just before the points, the car will track through. Another quick-and-dirty fix I’ve is is to mechanically lock the throw bar so the point can not be picked.

Terry - My Accucraft wheels are likely the most recent version (EBT 3-Bays) and perhaps some of the second oldest (NOS tank on flat cars). I will look closely at that too! When I bought my first Accucraft car I had heard the horror stories of their wheels and changed out that first car to Aristo steel wheels. I stopped doing that with later purchases.

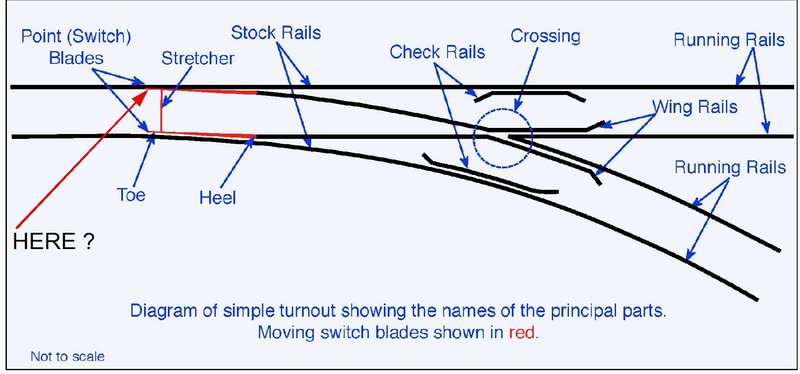

Stan - Just to clarify, you grind the stock rail where I’ve indicated with the red arrow; correct?

I have one switch that a train will go through for thirty times, while I’m working in the garden, but the moment I turn my back to go to the shop to get a different shovel, that’s the moment it will pick the points.

Steve,

It must be watching you closely. I have the same thing happen to me. These trains/tracks of ours must be developing/evolving intelligence of their own! ![]()

![]()

Jon Radder said:

If coming from the left to the right along the circle in the center and following along this same path to the right and down in the picture, and your trucks are taking the straight route (if I’m understanding this correctly), this is just a slight variation of what was happing to me.

As the truck follows along to the right it pushes its coupler/truck and that of the next car to the outside of the circle and this is forcing it to jump the points onto the straight section.

I would try a 6" straight before the turnout to the left so that when the train starts curving down to the right, the couplers are only dealing with one curve, instead of two, and this would reduce the swing. (Mine had to go after the turnout on the straight section, but the same the concept.)

Greg Elmassian said:

Todd, I went to George’s page on the wide radius switch, no mention of the guard rail nor picture of a shim, not to mention you as the inventor.

I don’t see evidence of you as the inventor documented anywhere, so please point it out, or rest easy on the fact that some other person in the world might have figured it out on their own.

My page references two people using brass strips, one .015 and the other using .025 … I have no pictures of the brass strip.

This is so long ago, I really don’t remember how it came about.

Greg

The link that I had provided used to take you to the LGB Turnout Tune-up Tips and George had the picture there with proper credit. That link doesn’t seem to be working for me though most of his other links, including those pre and post do still work.

This link takes you to his main page and you follow down will see “Trackwork” then "LGB Turn-out Tune Up. Get that link to work again, and you will get the picture and acknowledgement.

http://www.girr.org/girr/tips/tips.html

But you know that’s not my only invention and you have at least one other on your site that you don’t credit me with (i.e., the tool to put AristoCraft ties on the track without removing the track from the ground). And you know that was my invention.

Steve Featherkile said:

I have one switch that a train will go through for thirty times, while I’m working in the garden, but the moment I turn my back to go to the shop to get a different shovel, that’s the moment it will pick the points.

Moving trains, in a garden railroad environment, should be closely observed - just like very small children!

I exchanged the frogs in my Aristo 10ft. radius switches for the newer ones, offered a couple of years or so ago by Aristo which did improve the travel through the switches of my rolling stock. Aristo and Bachmann wheels seem to run fine - on this railroad. I think it is the San Val or USAT ones that have a wee ‘bump’ as they travel through. My Aristo track gauge (brass track) has never been any issue - whatever the dimensions - but then most of my stock is Aristo or Bachmann Big Hauler. Uneven ballast can have a derailling effect on locos, but that is not fault of the track or switch. Presumably other makes of track have similar issues.

OK, I did some work (and you could have found it this way also)…

Using the “Internet Wayback Machine” I found this:

“Todd Brody found that he could reface a damaged plastic guard rail by bending a 1/64” thick by 3/32" wide brass strip around it as shown in the photo. He found specific instances where this improved tracking. I’ve tried it also and it hasn’t worked so well for me. This does get rid of the glue problem however, and the piece is removable and replaceable. Note that brass strip is usually die cut such that the edges on one side are rounded and the edges on the other side are sharper. The rounded edge should be the one facing the wheels."

There is indeed a picture.

So, while no date is specified, I believe this was at or before Oct 5, 1997.

George does go on to say:

“The gap between the guard rail and the stock rail is too large which allows the wheel at the frog to drift into the frog. I glue a 20 to 30 mil styrene or brass strip inside the guard rail to tighten up the spacing. This pulls the wheel on the stock rail over tighter against the stock rail and tends to allow the other wheel to barely slip past the frog. This solution has been effective as long as the added strip stays attached to the guard rail. As discussed below in The Impact of Adhesives on Tie Strips, few adhesives stick well to LGB tie strips.”

So, while we were talking about ARISTO switches, your guard rail shim on the LGB switch is the same type of fix.

I hope you feel that I did adequate research on your invention claim

To summarize: The picture is NOT credited to you specifically and now has been removed from his site, in fact the entire page.

Likewise I don’t have your picture on my site.

So maybe years ago I when I read George’s site I might have seen your name, but I did not remember that it was you, so NOW I KNOW it was you that was reference on the NOW NONEXISTANT page on GEORGE’S SITE… but before all this fuss, I would not have remembered you were the one on his site.

I have removed the tool picture from my site too… and there are no other references to you or pictures of yours I can find on my site.

Anything else you want me to delete from my web site?

Greg

Greg Elmassian said:

OK, I did some work (and you could have found it this way also)…

Using the “Internet Wayback Machine” I found this:

There is indeed a picture.

So, while no date is specified, I believe this was at or before Oct 5, 1997.

I have removed the tool picture from my site too… and there are no other references to you or pictures of yours I can find on my site.

Anything else you want me to delete from my web site?

Greg

IIRC, George took the picture in 1997 at our first open house the day before Halloween, but when he saw the brass guard, he was unclear on the concept. It was not to fix a damaged guard rail as he states nor did it have to do with adhesives. In 1997 the turn-outs were brand new as was the entire layout.

It was specifically to address the problem of the heavyweights through that turnout, and John McGiver (sp?) came by and ran his heavyweights pulled by his Pacific through there and had the same problems. Again, the brass was not totally effective in this application, but the concept had been established.

I had no problem with the pictures of the tool to put the ties on the AristoCraft track, while still in-place, on your site and never even saw it until I went looking for the brass shim on the guard rail after I found George’s link no longer works. (I’ve never even looked at your site except a couple times in bits over the years.)

I only wanted you to give credit where credit is due. But if you would rather pull the picture than acknowledge the inventor…, hey, that’s your perogative.

It’s not important enough to have it on my site if you are going to stamp your feet about “credit” and “inventor” when a simple email would do, asking for what you want.

If every “inventor” on my site needed to be identified as such, I’d be spending too much time with that, rather than providing a site with 550 pages mostly for the benefit of others.

By the way, there is another reference on George’s site:

Bob Poli writes: “I have also found that closing the space between the guard rail and active rail helps to keep the flange out of the frog. The only success I’ve had with bonding is to first drill small holes in the plastic rail then bond either brass or styrene strips, I prefer brass, to the side of the plastic rail. I use 5 minute epoxy. The real bond is created by the mechanical bond of the epoxy flowing through the holes and out the other side of the rail. It’s best to coat the surface of the plastic rail first and make sure the epoxy goes through the holes. Then apply the brass strip which is preformed to the curve. Try and get some epoxy to encapsulate the brass as much as possible also rough up the brass with some emery paper to help the epoxy to stick. This should last indefinitely and it does help keep flanges between the rails.”

So I am NOT convinced that you are the INVENTOR… and it appears the Bob Poli’s involvement PREDATES yours.

So, I think you need to do some more research before you claim you “invented” the brass strip on the guard rail of a turnout.

Greg

p.s. by the way, how are you able to comment on George’s page when you cannot access it?

He does NOT state that it was to fix a damaged guard rail… you are again in error… the fix is to address derailments.

It’s time to get your facts right… I have the link to George’s web page, perhaps you should READ it.

https://web.archive.org/web/20030216060256/http://www.girr.org/girr/tips/tips1/lgb_1600.html

Greg Elmassian said:

p.s. by the way, how are you able to comment on George’s page when you cannot access it?

He does NOT state that it was to fix a damaged guard rail… you are again in error… the fix is to address derailments.

It’s time to get your facts right… I have the link to George’s web page, perhaps you should READ it.

https://web.archive.org/web/20030216060256/http://www.girr.org/girr/tips/tips1/lgb_1600.html

I can access it though my internal memory within my brain. But now that you’ve found a way to get the link to work, this is exactly what it says:

Todd Brody found that he could reface a damaged plastic guard rail by bending a 1/64" thick by 3/32" wide brass strip around it as shown in the photo. He found specific instances where this improved tracking. I’ve tried it also and it hasn’t worked so well for me. This does get rid of the glue problem however, and the piece is removable and replaceable. Note that brass strip is usually die cut such that the edges on one side are rounded and the edges on the other side are sharper. The rounded edge should be the one facing the wheels.

Note that the turnout is brand new. So who is in error and who needs to get their facts straight?

You could simply have said that, Todd Brody has come up with a tool to replace the AristoCraft ties… rather than someone has…

I think the ego requirements have been telegraphed to me very accurately.

Where is your retort to not being the inventor? Give me the proof that you are the inventor of the brass guard rail shim and Bob Poli is not.

I see you have shifted the focus from you being the inventor of the brass guard rail add on to the trivial points of making some forked tools and failed to get them into production and or market them.

This is kind of like hearing you whine at regular intervals about your “super special” bracket for an alternator or something, and the problems with it. I do not think it has changed the course of history.

If you are feeling unappreciated, beating others about the head won’t fix it.

It will though, make sure that others, like me, will go to lengths to avoid anything associated with you.

Greg

Greg, Went to your page(s) on track and wheels specs. The Aristo gage that you recommend to use after bringing into specs doesn’t seem to be available. So… what do you recommend to use now, or with my limited new skills on my milling machine, should I try to make my own?

From the Saskatoon Railroad Modelers site. I made one and it is invaluable for setting wheel and track gauge.

I’d actually take a piece of stainless or aluminum and cut it into a go/no go gauge for the back to back, and one for the track.

Or you could buy a set of vernier calipers from Harbor Freight for $15-20

Greg

Jon Radder said:

Stan - Just to clarify, you grind the stock rail where I’ve indicated with the red arrow; correct?

Jon

Seeing as our updated Bat Yard has 8 of these turnouts that need to be improved, I will take photos and post them. Likely take a few days.

Terry

The origional Accucraft wheels were terrible and have been removed from the railroad. The new ones are actually very good.

Improving the points and frog of the Aristocraft 10 ft radius turnouts is relatively simple and does reduce derailments.

Stan

Greg Elmassian said:

I think the ego requirements have been telegraphed to me very accurately.

Where is your retort to not being the inventor? Give me the proof that you are the inventor of the brass guard rail shim and Bob Poli is not.

I see you have shifted the focus from you being the inventor of the brass guard rail add on to the trivial points of making some forked tools and failed to get them into production and or market them.

This is kind of like hearing you whine at regular intervals about your “super special” bracket for an alternator or something, and the problems with it. I do not think it has changed the course of history.

If you are feeling unappreciated, beating others about the head won’t fix it.

It will though, make sure that others, like me, will go to lengths to avoid anything associated with you.

Greg

Very interesting! Shims - all kinds of different materials - are almost as old as the hills. Regularly used in instances were parts are worn, the tolerances incorrect or as a “it will be good enough” measure.

Adding shims to the check or wing rails is not a great invention, it’s just a quick fix. In my opinion checking track and wheel components for conformance to a standard (I don’t care which standard) is a no-brainer.

Guess why I scratch build my own turnouts using a specific standard … I like things that work as intended. Life is too short.