There are plenty of fine bits, that could be adapted …

https://www.riogrande.com/category/tools-and-equipment/burs-and-drills/burs

Scroll through for sizes and shapes.

There are plenty of fine bits, that could be adapted …

https://www.riogrande.com/category/tools-and-equipment/burs-and-drills/burs

Scroll through for sizes and shapes.

Right, or Dremel bits even, if the router could accept 1/8" shanks.

Thanks John - I will check that source out. I believe due to rotational speeds they need to be certified by the machine maker: Gerber.

and Cliff… Nah - needs to be 1/4" shank.

I just checked Gerber’s bit catalog and they have standard bits in diameters as small as 1/16 which I think is a little heavy for brick mortar lines. They have engraving bits that go much smaller - just need to see how they work in th HDU foam.

I did a cnc router for my first couple buildings, I used 1/8" shank, not sure but i think I used .040 diameter cutter. Did a good job, I prefer the laser just because it is easier in the

all around performance and variety. But if i did not have a laser I would cnc router all of what I would want.

Have fun is the key.

Dennis

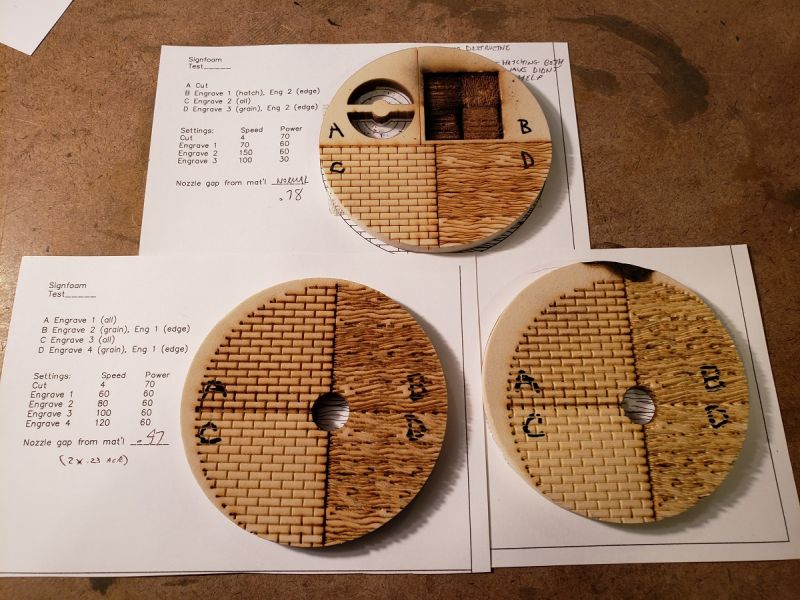

I did some more experimenting today, using an alternative to Precision Board called SignFoam. I’m trying to get proper samples to play with, but I’ve been sent 3 artsy samples like this.

These are 3/8" thick, CNC routed. Notice how fine their engraving is, at least as thin as 1/32.

The reason I’m interested is that this is more easily gotten for me, with free shipping (from Harbor Sales). They don’t like to deliver to residences, so I might have to meet the driver in some parking lot. But that’s a lot better than the high costs I was quoted for PB (139 per 4x8 sheet, 1/2", 15 lb; plus $259 shipping, plus tax). Harbor sales price for same in Signfoam: $129 per sheet, free delivery, no sales tax.

I decided to use these small SF samples for some testing today. I wanted to check the flame-retardancy (they claim self-extinguishing), and see how it took to engraving bricks & grain. Also nozzle distances, and more on the effects of speed and power settings, like Dennis suggested.

It seems to do just as well as Precision Board, with one difference: there wasn’t that surface layer that was hard to break through (but maybe that was an older PB sample, who knows).

My fave was this one, ran with a 1/2" gap from nozzle to material.

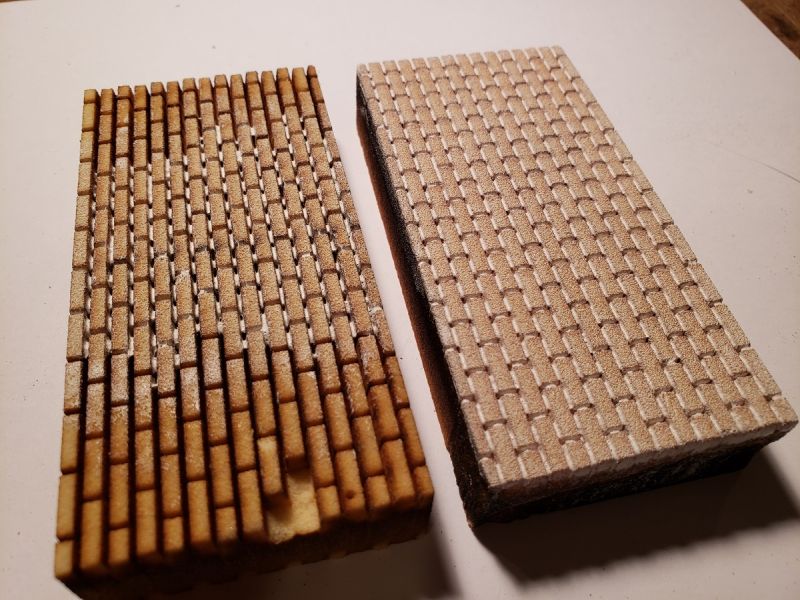

Of course, the effects can be easily lessened (this grain is too deep). But the mortar lines are really crisp, 1/32 wide and and 1/32 (lower far corner) to 1/16 (upper far corner) deep.

I’m relieved it didn’t want to cat fire (I really tried to light it, but it wouldn’t take). So Signfoam and Precision Board seem to be safe in this regard. BUT, other brands of HDU board WILL torch right up. I tried this with Corafoam and Jasper. Those cannot be used with lasers; but they’re cheaper though, and can be routed and used outside.

One issue with painting Signfoam is proper priming to close the cells. In our shop it takes 2-3 coats of a specialized primer (don’t have details at home). With that in mind, exaggerated cuts may be best as the primer will fill them in a bunch. The primer could stand in for mortar if the brick faces are then painted with a pad or very fine roller.

Jon, is Signfoam any worse than Precision Board in that regard? I’m looking at samples of the two, they seem optically identical in regards to porosity, with SF looking less so.

Thanks for the width / paint buildup tip!

Jon Radder said:

One issue with painting Signfoam is proper priming to close the cells. In our shop it takes 2-3 coats of a specialized primer (don’t have details at home). With that in mind, exaggerated cuts may be best as the primer will fill them in a bunch. The primer could stand in for mortar if the brick faces are then painted with a pad or very fine roller.

Honestly I think it’s called Sign Prime (hehehe) seriously though

I’m not certain. We work with a couple of different suppliers of HDU foam board and buy whatever is least expensive on any given day. I have not seen (that I recall) the brand name Precision Board on any. Is it more green? We do occasionally get a greenish one that seems to be a finer foam.

I guess what I am trying to say is that before you lock in your settings; try painting your samples and see where it goes. A standard acrylic primer like 123Plus should work for you.

Rooster ’ said:

Jon Radder said:

One issue with painting Signfoam is proper priming to close the cells. In our shop it takes 2-3 coats of a specialized primer (don’t have details at home). With that in mind, exaggerated cuts may be best as the primer will fill them in a bunch. The primer could stand in for mortar if the brick faces are then painted with a pad or very fine roller.

Honestly I think it’s called Sign Prime (hehehe) seriously though

It might be in your part of PA. The one we get is a regional product mixed up by a cottage industry sign carver. It has no MSDS and no ingredients listed on the can. The first time I used it I wasn’t sure what to thin it with so I experimented with everything and found it to be water based. Label says DO NOT THIN, but it was too thick to get through my HVLP gun with a 2mm tip!

Yay, product I already had! Testing now…

(with Precision Board; I’m out of Signfoam samples)

Cliff I buy 6 sheets of 2ft x 5ft, they ship UPS, besides much easier to handle than 4x8 sheets, and cost less to ship.

I spray mine with a good aerosol primer then brush with it a paintbrush to get into cracks, lays it all in the mortar lines.

Dennis

Thanks Dennis, good to know. I’m aiming to get 4x8 sheets that are cut to 20 & 28 wide, to reduce waste (my cutter does ~20x29 max).

The 1-2-3 primer laid down really nicely when dry, didn’t fill much at all. So I’ll plan on 2 or 3 coats of that, as Jon has to do.

I notice when the laser starts and stops, or maybe its just where 2 lines cross, it leaves a little pinhole that’s noticeable with the brick pattern, so I’d like the primer / paint to at least fill those in.

Here’s the dried bricks. The one one the left is too deep, but I like the width of the mortar.

Home Depot has 2’ x 2’ pink foam for about $5.00

Thanks Bill, it would be SO NICE if that material worked! (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif)

But the HDU (high density urethane) sign foam board products are much denser than insulation panels, like a replacement for wood. They’re meant to be routed / lasered, painted and left outdoors as signs. The insulation panels are expanded or extruded polystyrene, which is relatively soft and crumbly, and doesn’t hold up.

But thanks for bringing it up, that’s a good thing to clarify.

Cliff

You stated where your lines cross, are you rastering or vectoring your mortar lines?

I raster mine, so my lines do not cross, it cuts continuously from bottom to top.

Dennis

Dennis, I’m doing all the linework in 2D autocad, and have been using vector from that. Do you make a jpeg from your linework?

My lasers are run from the engravelab lasering program. anything more than a hairline is rastered, hairlines are vectored.

I draw it in CAD export into Engrav. I make the lines .040 and it rasters it at that width, and at 200DPI, quite fast.

My friend runs his laser on CAD all he does is fill for raster and vectors the lines.

Dennis

Thanks Dennis, you got me to hunt for vector-to-raster products. I located Inkscape, a free open-source vector editor that sounds like it’ll export for laser work. Not sure, but it’s the best free candidate I’ve seen so far.

[edit] Inkscape does import DXF (from Autocad or elsewhere) and save to SVG, PNG, lots of things, and scale them properly. That was my big first question. But when opening in RDWorks, it’s all white on black (no colors / layers that can be differentiated in power / speed). But, it’s a start. I imagine it’ll do the job; but it also looks like a learning curve I might not feel massively motivated at the moment to shift other priorities for. We’ll see. But it looks like a really great tool, and totally free.

Thanks again for putting the bug in me head Dennis… (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-yell.gif)(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-foot-in-mouth.gif)(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

Cliff

I have no idea what your driver program is that drives your laser, but that is probably where you need to investigate to figure

out how it rasters and then vectors. It may call them engrave, or raster, then vector and or cut. When I had a Chinese made laser for a little

while, their driving program was definitely a little clumsy, no that is a lie, it was very clumsy, but I could not change the driver system.

But the raster vector system should all be in the driver system. If you can use RD works I hear it is a more user-friendly than most

Chinese drivers. The one I had was not capable of switching drivers, my mistake of not finding out before I purchased.