Yay, product I already had! Testing now…

(with Precision Board; I’m out of Signfoam samples)

Yay, product I already had! Testing now…

(with Precision Board; I’m out of Signfoam samples)

Cliff I buy 6 sheets of 2ft x 5ft, they ship UPS, besides much easier to handle than 4x8 sheets, and cost less to ship.

I spray mine with a good aerosol primer then brush with it a paintbrush to get into cracks, lays it all in the mortar lines.

Dennis

Thanks Dennis, good to know. I’m aiming to get 4x8 sheets that are cut to 20 & 28 wide, to reduce waste (my cutter does ~20x29 max).

The 1-2-3 primer laid down really nicely when dry, didn’t fill much at all. So I’ll plan on 2 or 3 coats of that, as Jon has to do.

I notice when the laser starts and stops, or maybe its just where 2 lines cross, it leaves a little pinhole that’s noticeable with the brick pattern, so I’d like the primer / paint to at least fill those in.

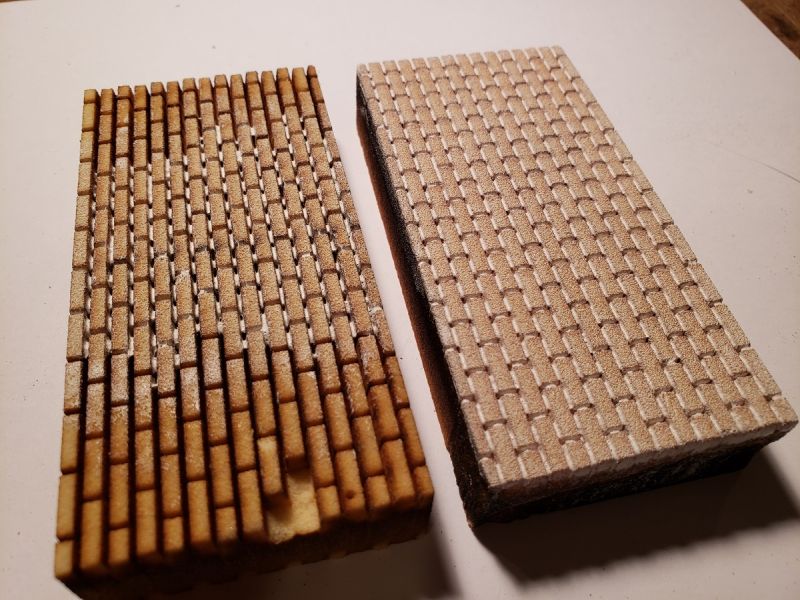

Here’s the dried bricks. The one one the left is too deep, but I like the width of the mortar.

Home Depot has 2’ x 2’ pink foam for about $5.00

Thanks Bill, it would be SO NICE if that material worked! (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif)

But the HDU (high density urethane) sign foam board products are much denser than insulation panels, like a replacement for wood. They’re meant to be routed / lasered, painted and left outdoors as signs. The insulation panels are expanded or extruded polystyrene, which is relatively soft and crumbly, and doesn’t hold up.

But thanks for bringing it up, that’s a good thing to clarify.

Cliff

You stated where your lines cross, are you rastering or vectoring your mortar lines?

I raster mine, so my lines do not cross, it cuts continuously from bottom to top.

Dennis

Dennis, I’m doing all the linework in 2D autocad, and have been using vector from that. Do you make a jpeg from your linework?

My lasers are run from the engravelab lasering program. anything more than a hairline is rastered, hairlines are vectored.

I draw it in CAD export into Engrav. I make the lines .040 and it rasters it at that width, and at 200DPI, quite fast.

My friend runs his laser on CAD all he does is fill for raster and vectors the lines.

Dennis

Thanks Dennis, you got me to hunt for vector-to-raster products. I located Inkscape, a free open-source vector editor that sounds like it’ll export for laser work. Not sure, but it’s the best free candidate I’ve seen so far.

[edit] Inkscape does import DXF (from Autocad or elsewhere) and save to SVG, PNG, lots of things, and scale them properly. That was my big first question. But when opening in RDWorks, it’s all white on black (no colors / layers that can be differentiated in power / speed). But, it’s a start. I imagine it’ll do the job; but it also looks like a learning curve I might not feel massively motivated at the moment to shift other priorities for. We’ll see. But it looks like a really great tool, and totally free.

Thanks again for putting the bug in me head Dennis… (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-yell.gif)(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-foot-in-mouth.gif)(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

Cliff

I have no idea what your driver program is that drives your laser, but that is probably where you need to investigate to figure

out how it rasters and then vectors. It may call them engrave, or raster, then vector and or cut. When I had a Chinese made laser for a little

while, their driving program was definitely a little clumsy, no that is a lie, it was very clumsy, but I could not change the driver system.

But the raster vector system should all be in the driver system. If you can use RD works I hear it is a more user-friendly than most

Chinese drivers. The one I had was not capable of switching drivers, my mistake of not finding out before I purchased.

Dennis, RDworks seems to be working fine for me. If you import a raster file, it’s all on one layer, with darkness of pixels governing laser power (which is adjustable). If you import a dxf (which I send from Autocad) it automatically sets up layers based on color, each of which you can set for power & speed.

Cliff

With what you said above, I gather you can SOMEHOW set up to raster your brick lines, if you raster the brick lines they will come out all smooth with no pin holes to deal with.

That is where, if you can reduce the DPI to around 200, rasters much faster.

Dennis

Thanks Dennis, it’s all making sense now.

Cliff Jennings said:

Here’s the dried bricks. The one one the left is too deep, but I like the width of the mortar.

I agree. I’m curios on the brick and mortar line dimensions you chose. My real world experience surveying late 18th and early 19th century brick structures is that the brick and mortar dimensions are all over the place. I don’t know when it standardized, probably when all the regional brick makers consolidated into a few high volume makers. Don’t know when that was.

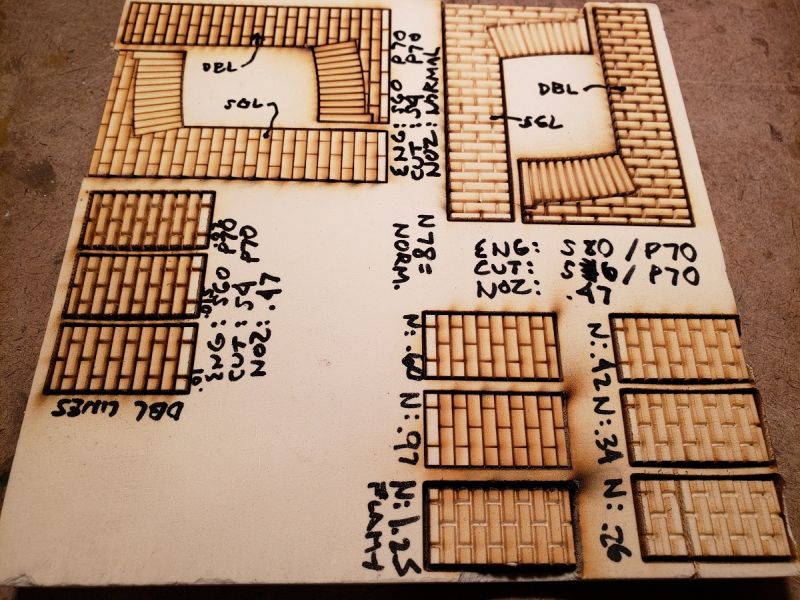

Just to close the loop on this, I did a few tests with stock Sign Foam (not the thin little sample disks).

In the upper section,I tested for speed / nozzle height a little, and also single-line mortar vs. double-lines. Like, .010 apart.

At the near left, continued to mess with double line mortar, while varying the distance between the double lines.

All that was fine and good, but I really don’t want to double the engraving time; and the upper right single lines were coming out pretty good. So I did a more basic test, keeping power and speed the same, while just changing the nozzle distance from the material.

I started with a height of just .26" at the lower right, and its engraving was kinda blurry and some flamey blow-back. But the next ones, .34 & .42, had nice brick definition, and really good cutting.

[edit to say that the success in this line of inquiry was just as Dennis predicted: “When vectoring set your focus at 1/4” deep…" Good call, Dennis!!]

In almost all of these patterns, there was little or no pinholing on either end of a line. I’m attributing this to the difference in material: my prior brick tests were with a sample Precision Board, which had a noticeably harder / different surface to get past before the laser really ate in. This material had none of that. Maybe the sample PB had been sitting in a box for a long time, who knows. But I’m glad to not see that problem here!!

As far as SignFoam ordering goes, I have good news. I put in my order over the phone on Tuesday afternoon (to Harbor Sales). Could have done it online, but I wanted to talk through the pre-cutting. The 4x8 x 1/2" (15 lb) sheet cost was $127; 1 cut per sheet (lengthwise) was $7. I got 5 sheets, and had to pay MD tax. But no shipping / pallet / delivery fees. So for about $707, I received 5 planks of 96x20 and 5 of 96 x 28, nicely bundled in cardboard, delivered. And I received it within 18 hours of ordering!

So, I’m really impressed with that supplier, and glad to have the stuff. Now, on to actually doing something with it…

===:>Cliffy

As usual, super helpful and informative, Cliff. Good luck with whatever it is you are going to build!

Thanks Jim! And you bet, I’ll be starting that project soon, thanks for your interest!

Cliff not sure which one you are in favor of but i prefer bottom picture middle left

Dennis

Thanks Dennis, gotcha.

Now that this experimenting is pretty much done, I’ll be switching over to a new thread which will hopefully tie all this to a real project.

It’ll be called Virginia City Flats.

Thanks Dennis and all this has been a huge help.

Cliff