After a few month in the shop some news on early diesel projects:

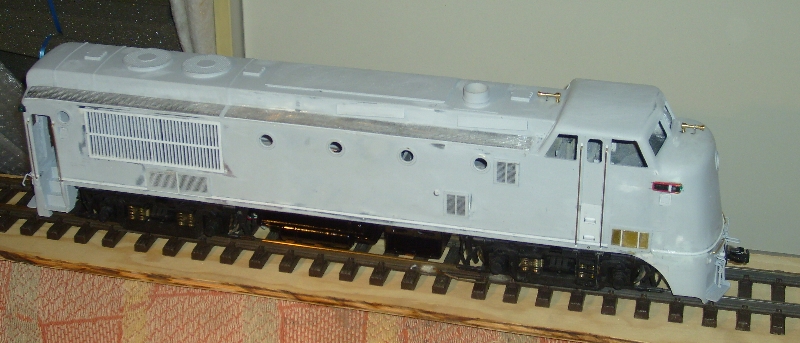

current status of the paint job on RI TA

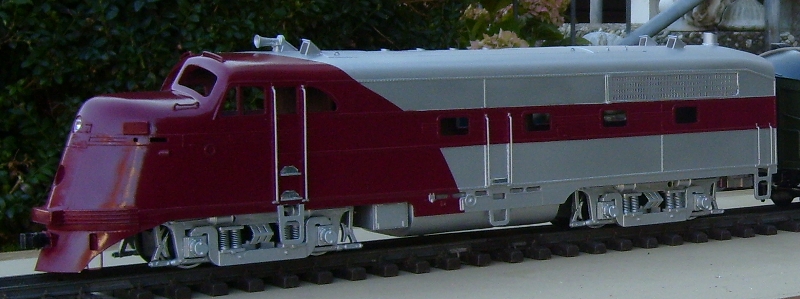

And with aRI baggage and a (soon to be re-lettered) streamliner

Meanwhile continued with an older project - Peoria and Pekin Union RY #200, a Davenport streamlined switcher of 1938

Started as an ugly ‘Frankenstein’-unit made of GE 44t -parts

And with a lot of putty, glassfiber layers and hours of sanding

Currently I’m dealing with painting the unit - I’d like to get the shell in a slightly lighter black than the frame…haven’t found the appropriate paint up to now

My RI #9006 with its prototypical short passenger train consisting on a baggage mail express and a coach

And started with GM&O’s #1900 - Ingalls’ sole venture in the diesel-electric market (1946)

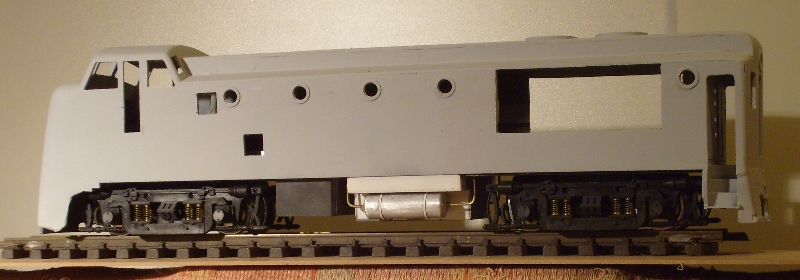

Used an Aristo-Craft FA, a Bachmann coach’s monitor roof, parts from my scrap box, a good amount of putty and a lot of phantasy to receive an ungainly start

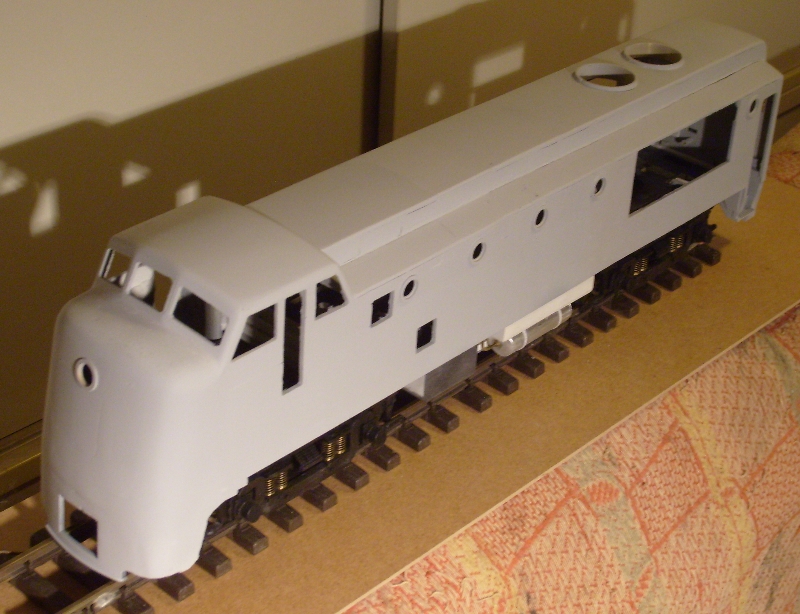

A few days later one can notice more resemblance with the prototype

And after several sanding-sessions (once again…)

Hope you’ll like it

Regards

Norman