Got the tunnel roof on, glued down with Liquid Nails. Coincidently it rained (and hailed! that’s a rare one!) so I was able to check that the small French drains at either end of the tunnel did their job. Near as I can tell there’s no build up of water inside, which was our main worry.

Of course, plenty can still go wrong, particularly as things age (I have personal experience…).

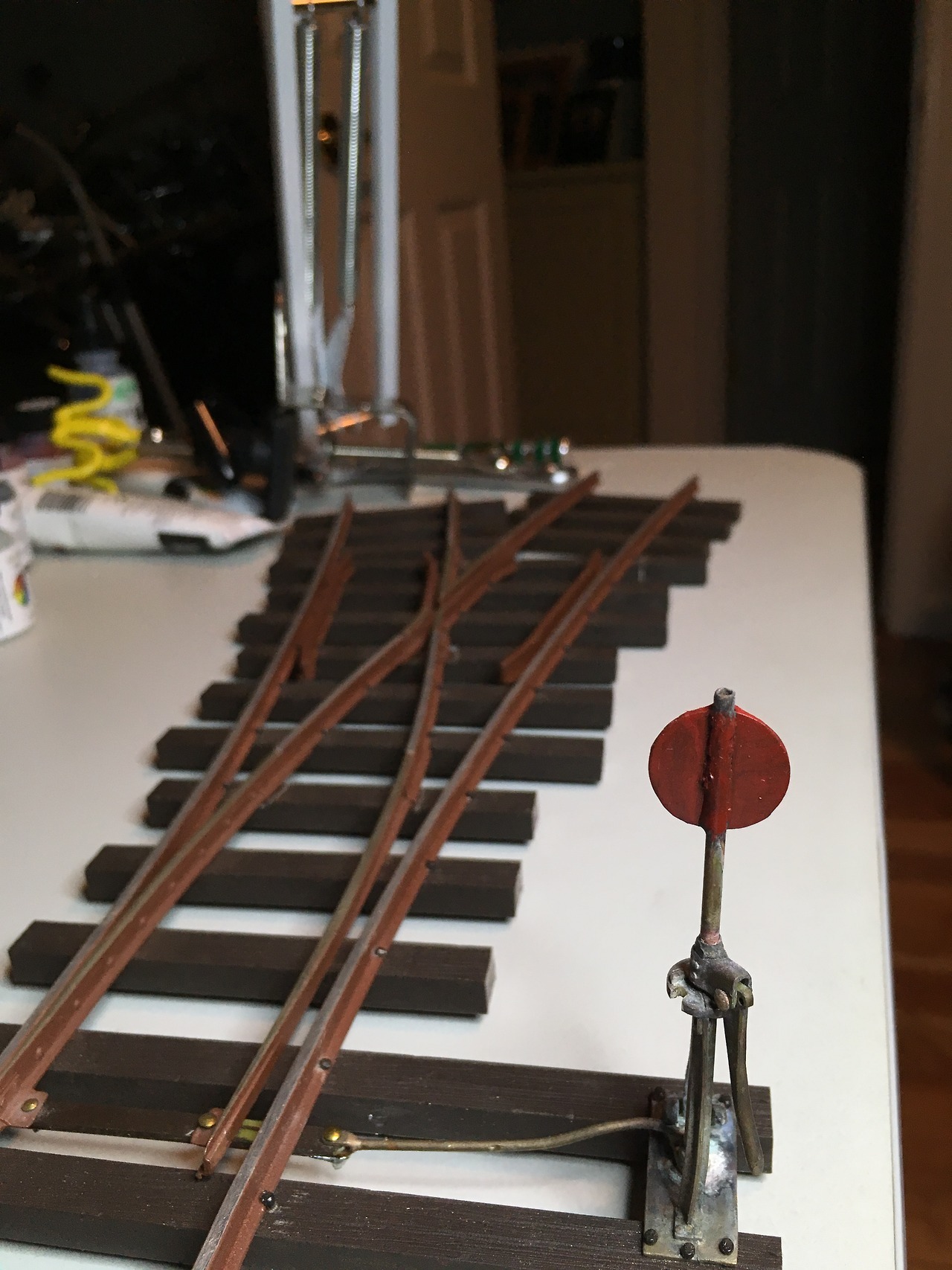

From the sawmill, Jasper side:

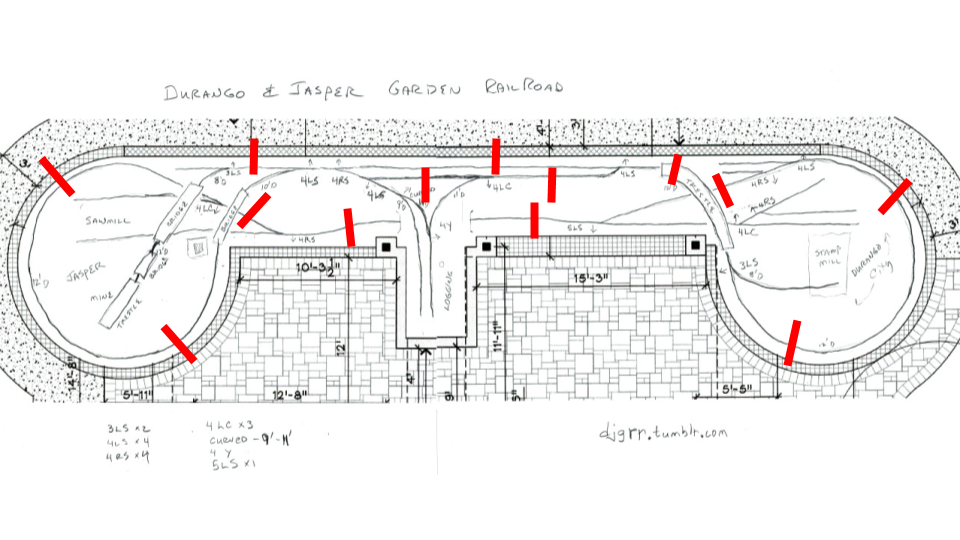

From the Durango side: