With the advent of low cost 2.4 GHz Spread Spectrum R/C systems, there has been a trend toward using them in their native mode (with servos) to control live steam, and with with an electronic throttle to control battery operated locos. The system works well but there is one big negative - the size of the transmitter. Low Cost equates to Park Flier Aircraft which equates to large 2-stick transmitters…

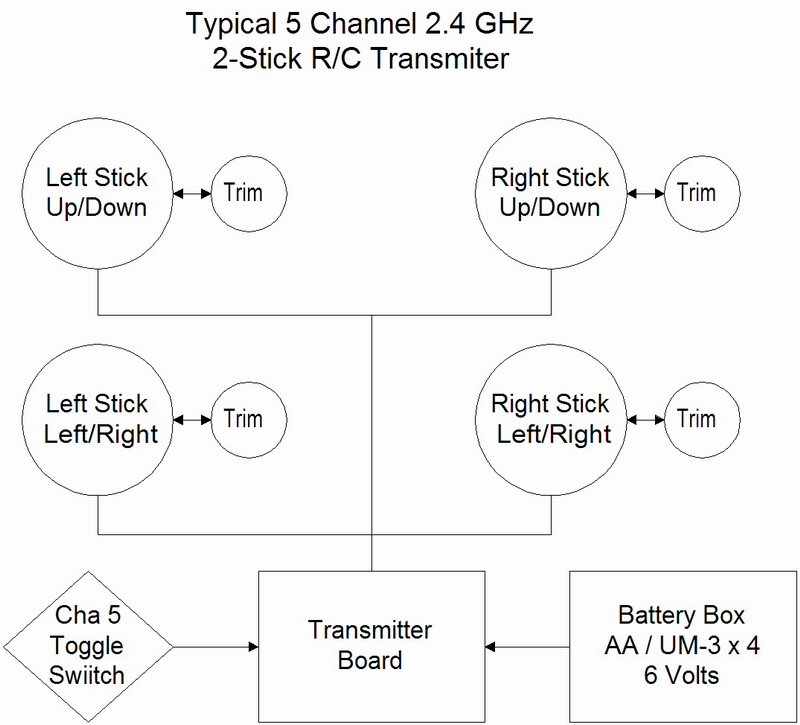

If one looks inside the large plastic box that houses the above radio, you find that the electronics are quite small and there is an integrated 4 AA battery box. The largest components are the sticks which aren’t really needed for train control. I drew this simplified lock diagram…

The above was done from memory, so I might have missed a few switches. It seems to me that it would be a fairly simple job for anyone with basic electronics skills to replace the stick components with something smaller and fit the whole works into something about the size of a small hand-held radio. The way I see it, the job requires just a few decisions, some of which I don’t have the data to make… 1. Which controls require more than on-off ? I think there would be only one - Throttle. but I’m not familiar with programming needs of ESC’s. 2. Which controls need 3-State switches ? I’m thinking Direction (Forward, Neutral and Reverse) but there may be others. 3. Should any controls be 2-State (On/Off) ? 4. Does trim need to be external, or would an internal trim-pot be acceptable? If external, would a small shaft be good enough or is a knob or slider needed? Given the answers to the requirements, it seems to me I would only need to measure the values output by the sticks in various positions, and replace them with either potentiometers, or a switched resistor network. I’d like to hear your opinions and feedback on technical requirements. This isn’t a project I’m likely to take on immediately, but it might be a good rainy day / hiding in the air conditioning / winter project.

It cuts the cost by utilizing one existing stick. Could you accept using the side-to-side movement on that stick for two of your four sound triggers (if an Eclipse ESC was used)? You could still do the horn and bell on push-buttons or toggles.

It cuts the cost by utilizing one existing stick. Could you accept using the side-to-side movement on that stick for two of your four sound triggers (if an Eclipse ESC was used)? You could still do the horn and bell on push-buttons or toggles.