That looks great Devon, keep going!

Well this weekend has been a bit slow. After a false start on the tin roofing I think I got something I like. I am shooting for that very rusty all red panel look. I stole this picture online but this is what I kinda want.

I used a cheap knock off instead quality Taylor Tin. I used pop cans and roller to make my own. Went to etch it with the Muratic acid and hydrogen peroxide and it just didn’t work. After asking on here it turns out that pop cans are coated which prevented it from etching. But I shot them with grey primer and then went to work weathering them. I used oil paints: burnt umber, raw umber, and burnt sienna at about 1:1:5 respectively. It needs to have a distinct red to it. I brushed it on and then stippled it to give it a rough look. After it dried about 24 hours I took red weathering chalk and with variation in heaviness of application made the chalk patchy. I think it came out alright.

I also weathered the windows.

And I built the tank support

The tank stand is going to have a ladder up to the platform and then another ladder up to a catwalk on top of the tank. It will need to be painted and weather to match first. The blue tape is holding the building down as it glues. I am hoping tomorrow to begin roofing. Its just about time to start on the head frame. I need to do some landscaping where I wont be able to reach before mounting the building to the piers permanently.

You did fine on weathering the tin. Your technique provided the depth you would see with real rust. A few bent corners here and there and you will have what you are looking for. The weathering on the window looks good too. I still like what you did with the red paint. It really looks like it has been on there for many decades.

Dan it will have bent and torn corners. I am even thinking a few missing pieces revealing old weathered shingles underneath. I am also happy with the red. I finally have a weathered peeling paint technique that I actually like. This build is teaching me a lot about weathering something I just haven’t done a ton of before on anything other than HO rolling stock. I tried some buildings in HO but honestly it looked horrible. I am liking the weather on this.

A little more work. One thing I have not really cared for in my arsenal is the shiny look of the stain I use for the timbers. I have dull coated it and it helps. But older creosote timbers take on a grey look. So I tried adding grey weathering chalk. I like it, dulls down the shiny and also adds that grey color. This picture really doesn’t show it off real well but when you see it in person it is a noticeable improvement.

The top portion shows the chalk and the bottom is untreated. I also messed with the roofing to see what it will look like.

Now I messed up two of the panels. The lower right and the second one in on the upper left got grey weathering chalk dusted on them while doing the frame. I brushed it off and well I think I like it. gives it a softer duller tone. Might have to do them all.

The roofing and weathering of the wood parts of the structure are coming out great. I see where you’re going with this and I think it’ll all fit together.

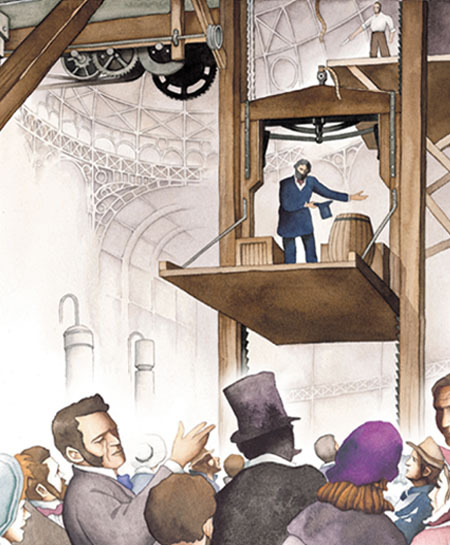

Well I seriously need to put some thought into the headframe now that the winch house is nearly complete. I have enough wood to do a rather simple wood frame structure which is what this mine would require. Its a single shaft mom and pop operation that has been running for about 30 years or so. So no elaborate headframe is required. But I do want a visually interesting piece, not just a bunch of timbers nailed together. So I have been combing literally hundreds of pictures of head frames. One thing that has dumbfounded me in this process is how buckets were dumped. I have found through research that this was accomplished in several ways stemming from very rudimentary systems where a rope was attached to an eye on the bottom of the bucket and then a second winch just lifted the bottom of the bucket tipping it. Then there are some rather interesting automatic tipping systems. What it boils down to is that basically at every mine they did something different based on several design concepts. One of which is a door system where the bucket is hoisted above a door that is hinged. Once the bucket clears the door, the door is lowered on an angle and the bucket is lowered onto it and tips and dumps its load into a chute that puts it in cart. That cart is then rolled “trammed” to the ore bin. So with that here are some design ideas.

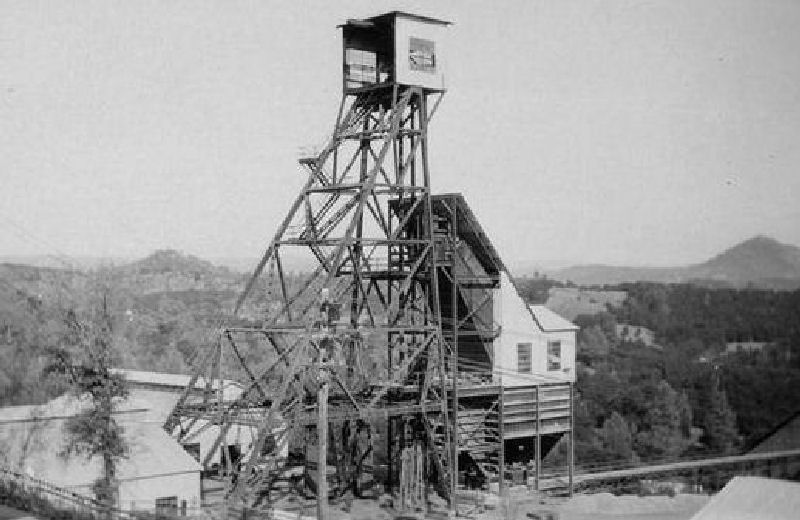

For the head frame I kinda like this design only minus the ore bin.

I like the rectangular framing that is distinct from the A framing. So I will likely build something similar to this. However, my mine will have a tramway from the headframe to the ore bin so instead of the ore bin There will be a “tipping” room. An open sided covered area where the cart sits and then a tipping mechanism and chute. Something similar to this.

only much simpler.

The operation is a low budget few man operations. So there will be one engineer/top man who does it all. He is responsible for running the winch, tipping the buckets, tramming the ore carts, etc. That means he needs to be efficient. A cat walk from the winch house to the head frame is a must. The tipping house and tram will be at the same level as the winch house or maybe even a bit higher. The tipping mechanism will need to be operated from winchhouse so he can operate all the controls. Well this is not my idea I go this from an old mining practices book on Google.

here is another drawing of a similiar design I found online

So this idea is coming together nicely. A rope and counter weight system will be run to the winch house that operates the door. The engineer can raise the bucket, activate the door, dump the bucket, raise the door, and lower the bucket from the winch. He then will scurry over to the tipping room and tram the cart to the ore bin and dump it, return the cart, and scurry back tot he controls all in the time the shovelers in the mine are filling the bucket again.

Now that is the design idea, now I have to make it with the remaining wood. I likely will have an over run on wood and I am remembering rule #1 is more important than the other rules. Another option is to make a steel headframe which is an intriguing thought.

I can’t wait to see what you come up with. This is gonna be good.

John Passaro said:

I can’t wait to see what you come up with. This is gonna be good.

It might be. One thing I would like to do is make the whole operation. . .well, operational. It will take a minor amount of retrofitting to the steam winch I already have to allow me to rotate the drum. But I think I can do that and if so the rest of it should be easy enough to do. Time will be the biggest factor. Might have to just make it and then make it work later.

This Kennedy mine in CA is quite an inspiration. Since finding it I have poured over its design and just think its about perfect for what i am shooting for. I am not going to replicate it but it has many design features I really like. It has the covered top on the head frame which is cool. It also has a covered “house” where the ore cars are filled. And a tramway that led to an ore bin or possible in their case a mill. But none the less it has many features I like. It also has a mine bunkhouse which is a future design element for the area. I have found my inspiration.

Wow! Great build! Great research! I’m learning a lot from your posts.

I believe you said you had some old Model A’s …perhaps you should take a look at their leaf springs and consider an “Emergency Brake” in case the rope fails so you don’t piss off OSHA

Bite your tongue Rooster. I would never have a model A. Ford might have made automobiles accessible to the common man but Chevrolet haves them class and style. Although I can think of no better use for a model a other than to scrap it and use it’s parts for a more useful purpose. Now with that said where in the hell would you put leaf springs on that rig and for what purpise. I am not following

Devon Sinsley said:

Now with that said where in the hell would you put leaf springs on that rig and for what purpise. I am not following

Muddy Creek Forks general store on the old MA&PA has your answer. BTW it was also know as Yoders Store in the movie “For Richer or Poorer”

Hollywood has the answer as well and loves to explain stuff like that…Me I just analyze pictures and reality.

Thanks for sharing the head frame drawings, Devon. At some point, I want to build a mine and those drawings will come in handy.

Dan Hilyer said:

Thanks for sharing the head frame drawings, Devon. At some point, I want to build a mine and those drawings will come in handy.

Read this. This is where I got the info from. It has some good info. This is specifically on the dumping system but the whole book has some good stuff on building mines especially timbering it.

" Rooster " said:

…Me I just analyze pictures and reality.

You get paid hourly for that, or are you on salary?

So I am not much of a Sketchup guy though I have played with it. One thing i like about it is that I can visualize the building process without actually cutting anything. It shows me what will and wont work for the most part. The other thing it does is allow me to butt model with actual benefit. I sit on my butt when I can’t model for real and still design my concepts. Here is the beginning of the head frame design. I have yet to add the Model A leaf springs (still not sure where i am supposed to be putting them (http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-tongue-out.gif)).

The tipping table. This shows the table top where the appendage on the bottom of the bucket catches as the bucket is lowered causing it to tip and dump its load. And I still need to add the sluice chute to it (sorry John).

and how I will hinge it

The “tipping house” platform will be elevated 18’ (9") above ground level. this will be constructed on the front end and will house the tram carts and track.

this is the rudimentary design concept. Now time to start building it.

When the rope breaks; the brakes are released to catch the sides …

See?