Yes these machines will cut the 2 layered acrylic, the top surface is usually from .001 to .010 thick. Most is around .003. One way to explain

a laser, is a printer applys ink to a surface, and a laser removes from the surface.

The layered acrylic usually comes around .062-1/16" thick with the cap being around .003. The laser removes the surface exposing the color underneath.

JDS Industries is a nice place to purchase the needed acrylic, and they have outlets across the USA.

I use their solid color acrylic, it lasers very nicely, comes in 1/32-1/16& 1/8, it is under their ADA acrylic.

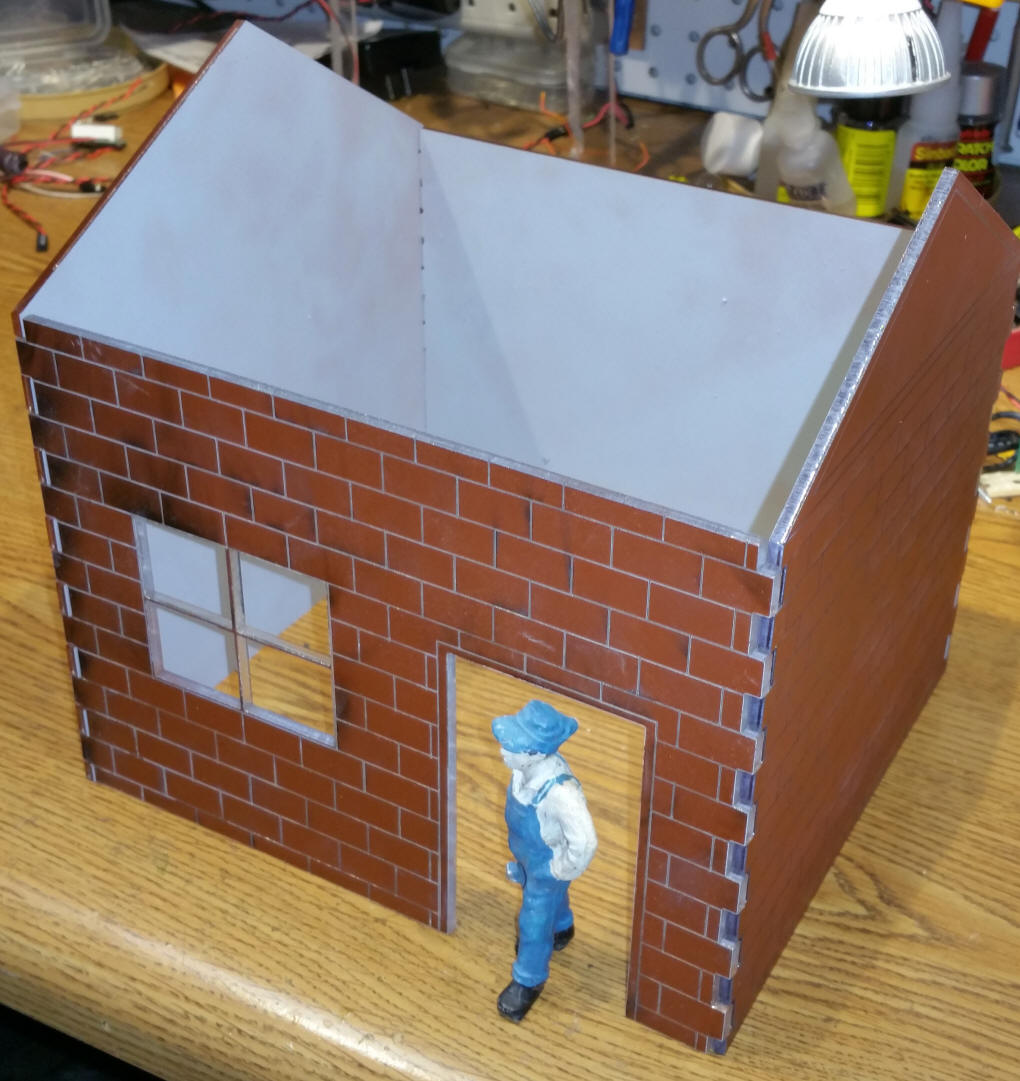

for doors and windows it works great, more flexible than standard acrylic, so when lasering leaving .035 for window mullions

being flexible allows you much better luck.

Yes it is more costly than styrene but lasers smoother…

12"x24" for 11-13 bucks will cut out 100 bucks worth of windows. Making windows with your size and design can be fun.

Multiple layers can create some very unique windows.

There is metal that has a coating on the surface for lasering off, leaving bare aluminum, removing a white color leaving a few colors

like black, brass, copper, and others.

Co2 laser cutting metal, is ALMOST an absolute no. Kern lasers makes one 100,000.00 plus. works very well, and Epilog makes one that will engrave metal.

40,000 plus.

There are chineeeese ones that will cut some too, not familiar.

Most all metal cutting lasers are what is known as YAG lasers, completely different than Co2.

One of the many Doors I have made for myself

These machines can be so much fun,

Dennis