A few months ago a question came up about cutting a square hole in wood or plastic - I posted a reply showing how I do such cuts with a Harbor Freight multi-tool.

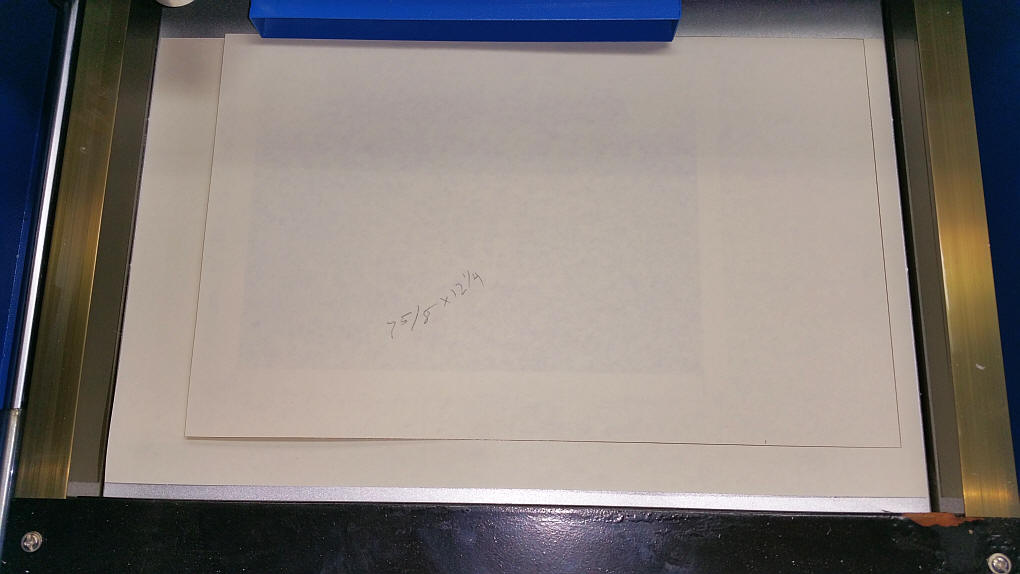

I recently purchased an inexpensive laser engraver / cutter from eBay and, to say the least, I am thrilled with its performance vs price!

I did a few videos and have some notes on my web page here:

http://trainelectronics.com/LaserEngraver/

Please note that this page is not complete - there will be more to come as I experiment -

dave