Randy Lehrian Jr. said:

A good friend of mine just got one of these. It’s actually the next generation of the same machine that Dave got. They are not plug and play. You should expect to have to do some minor wiring, maybe fix a broken part or two. Mirror adjustment is another big factor. He made little paper labels to put on mirrors that way he could see where the laser would darken the paper and know where it was hitting. He has been tinkering with it three weeks now and just finally produced a good etched part yesterday. He has used lasers before so he had prior knowledge. He did say the instructions were useless, and had no information on power settings, mirror alignment or machine adjustment.

At the end of it all he is very happy with it. It just needs to have some time put into “tweaking” before running. He did mention that larger laser tubes could be put in this model but it involves a cabinet extension and mirror recentering. Lots of extras for this machine at light object.com

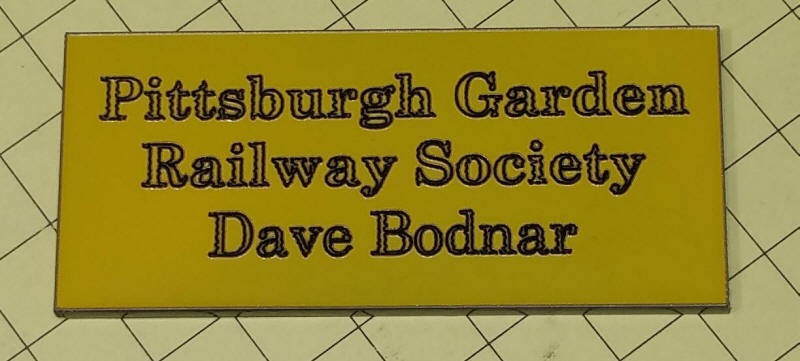

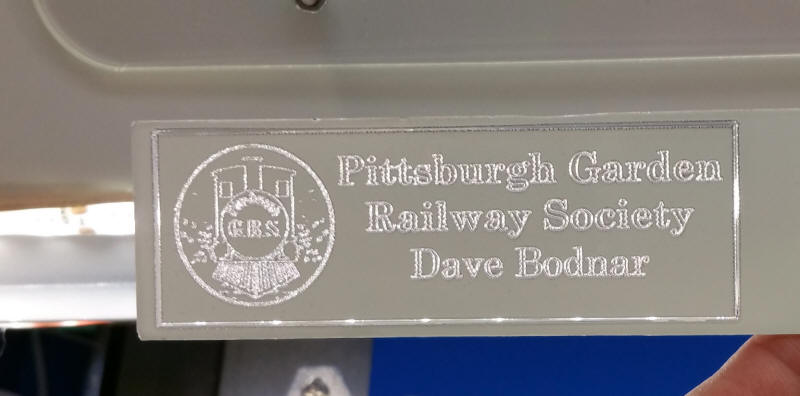

I fully agree that they are not plug-n-play, Randy, but I am surprised that your friend did not get it running well sooner than you describe - We, literally, had it aligned and printing (etching?) in less than an hour after getting it unboxed.

Perhaps we were lucky that only one mirror needed tweaking and that I have had a great deal of experience with 3D printers and CorelDraw. I also read extensively about the machine and viewed many, many videos while waiting for delivery!

In any event, it is a super machine- I have a few more things that I’ll be adding to the web page soon.

dave