Here’s my thoughts as someone that cuts styrene on a regular basis and is a styrene hoarder.

Yes, the Brynes saw is worth the money if you can find one second hand now that Jim passed. I wouldn’t sell mine so it’s gonna be hard! Even with a cheap MicroMark table saw I was able to cut strips just fine. Use something to hold down thin sheets and you’ll be fine. I cut down to .030 by .010 just fine.

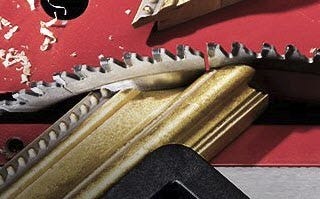

.060 to .125 cut just fine with a fine tooth blade on slow speed. I’ve also cut those on a full sized saw but lots more waste with a bigger kerf.

.040 below it’s easier to use a knife or other cutting tool.

You can still score and snap up to .125 but as you said it leaves a rough edge.

A plastic supply house will be a lot cheaper. By 4x8 sheets and either have them cut them or do it yourself. I tend to buy .030, .060 and .125 4x8 sheets.

A paper cutter won’t work. I’ve tried. It works okay on .010 or .015 but that’s about it.

Another solution I haven’t tried yet for .030 and below is using a CriCut type machine.

PS, buy yourself one of these. I use it all the time to scrap the “V” edges off score and snapped sheets or to remove the melted plastic when using a mini table saw.

https://www.tapplastics.com/product/supplies_tools/plastic_tools_supplies/edge_scraper/588?gad_source=1&gclid=CjwKCAiAgoq7BhBxEiwAVcW0LJt9FIgQrgleiPQrp0lQDgmbXU2DTQ1Z3Bdd5hmr05ttPAkyOpMBxRoCqVcQAvD_BwE