Gents,

Thanks for the tips and humor (or humour, if so inclined!). Here’s where this project stands going into the weekend…

I got the frame filled and sanded. It’ll do, even if not entirely square. I’ll use my commercial strip wood for the two needle beams (new term for me!), and I have some larger commercial strips to serve as bolsters for the trucks.

The bolsters are

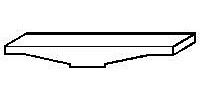

the next engineering hurdle. While Kid-zilla and senior members of the 1:24 gang inspected a battered LGB combine from the tub-o-trains (likely our next project), the rest of us headed out to the rails to do some pre-cutting testing. The trucks have to swing enough to pass through the R1 curves. Mounting them to the frame won’t work, and, as testing showed, mounting a bolster that would run all the way across the frame was equally over-constricting. The answer will be a bolster the width of the LGB trucks:

I plan to glue the bolsters to the frame, tack the trucks in place for testing, then, if that works, use wood screws to hold the trucks fast. If that doesn’t work, I’ll pry off the bolsters, glue them to the trucks, and let the bolsters pivot with the trucks. Goofy-looking is preferable to non-functioning!

Speaking of goof-looking, this flat car will ride rather high, courtesy of my choice of dimensions for the timbers.

I’ll get over it, and simply term it “robust.”

If all goes well, we’ll convert craft sticks to decking, and have a working, if cetainly unique, flat car by the end of the weekend. If all goes as it has to date, the frame will get another flight test…

Eric