I didn’t even know this technology existed until about a week ago:

It is primarily designed for 3d print farms - BUT - it can print VERY LONG PARTS on its Z-axis.

I should be able to print entire Pullman car sides (28") as one piece. I will be able to print my carrier ramp as one piece, and increase its length to a more desirable 24",

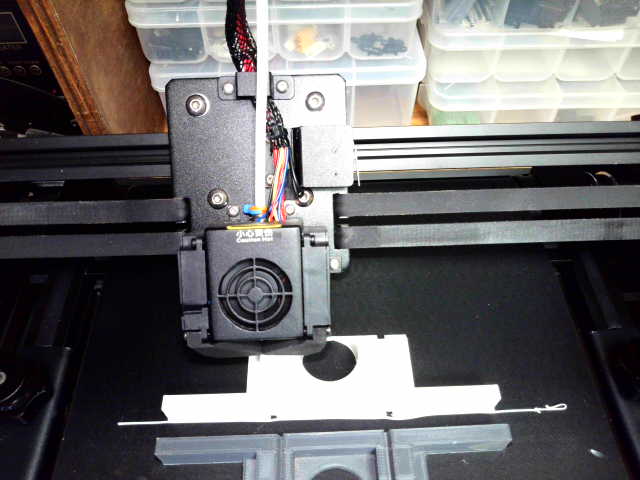

Here it is printing its very 1st test print:

I have no idea what it is, some sort of square cube I guess…

So the goal is to be able to print G-scale rolling stock. I should be able to print a Pullman car in six parts:

- Left side

- Right side

- A end

- B end

- Roof

- Floor/Frame

I plan to use Kaydee couplers and some sort of pre-built trucks.

=============================================================================

I will need help with the following:

- Painting and decaling techniques.

- Source of pre-built trucks.

- many other things, I know so little about this I don’t know what I don’t know…

=============================================================================

On the trucks, I want quality with metal wheels and axles, ball-bearings preferred.

On the paint I need sources of (close enough to) authentic colors such as Daylight Orange, UP yellow, etc.

Want to keep the costs reasonable. Expect to be making a lot of cars once I master the technique, so will want volumes greater that “Tester bottle”.

Sources for prototype decals. Considering the use of blank laser printer water-slide decal paper. Anyone have experience with that media?

============================================================================

Am setting up a new pi with Octoprint as I type this. Once that is working I start playing with some of my own prints.