Dave Taylor said:

Dan… Not to burst your bubble… But… I don’t see any means to adjust the depth interface between the two rollers… Very important to regulate the depth of the crimp, and the clearances between the rollers for any changes in material thickness, and annealed state…

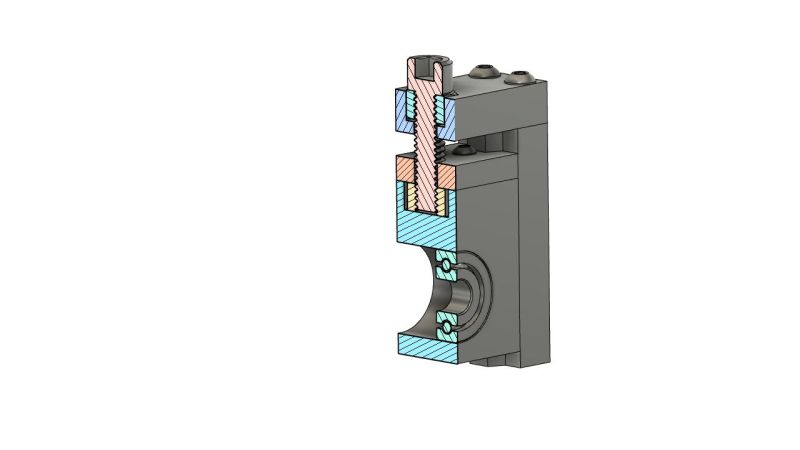

Details, details (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)… thanks for pointing that out, Dave. Believe it or not, I had thought about that early on in the design process but chose to fix the distance based on the 0.002 steel shimstock I am using. Probably should (will) make that change once I get the rollers printed. Question, regardless of the method used to adjust the height, there is always the issue of keeping the adjustment roller level because I am assuming, without giving it much thought, that the two ends of one roller will have to adjust independently. So how do you keep them level? Count turns on an adjustment screw? Pre set adjustment heights? Any suggestion?

EDIT: To ask one more question.

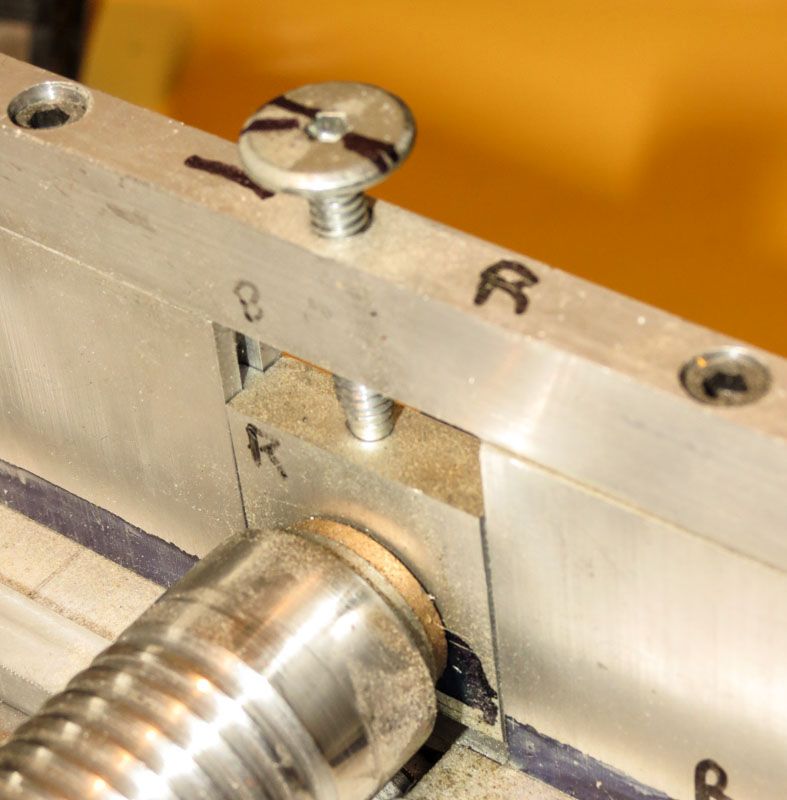

Dave, I considered trying a roller orientation as shown below, but I don’t think there will be enough friction to pull the stock through and its not stiff enough to push. Any thoughts?