Dan… what metal, or stock do you plan on using to make the panels from…?

Dave Taylor said:

Dan… what metal, or stock do you plan on using to make the panels from…?

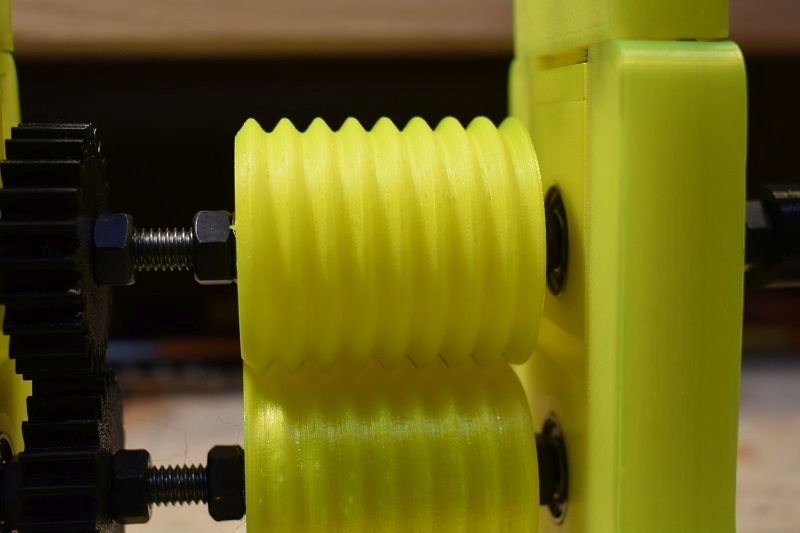

I’ve been using 0.002" steel shim stock with the paper crimper with success. I also have 0.003 aluminum and 0.002 brass I am going to try. I’ve discovered through testing that the roller profile must be a little more aggressive than I originally thought.

Pete Lassen said:

Dan are you at all concerned with the plastic flexing and not giving repeatable results, and will the plastic rollers wear out quickly?

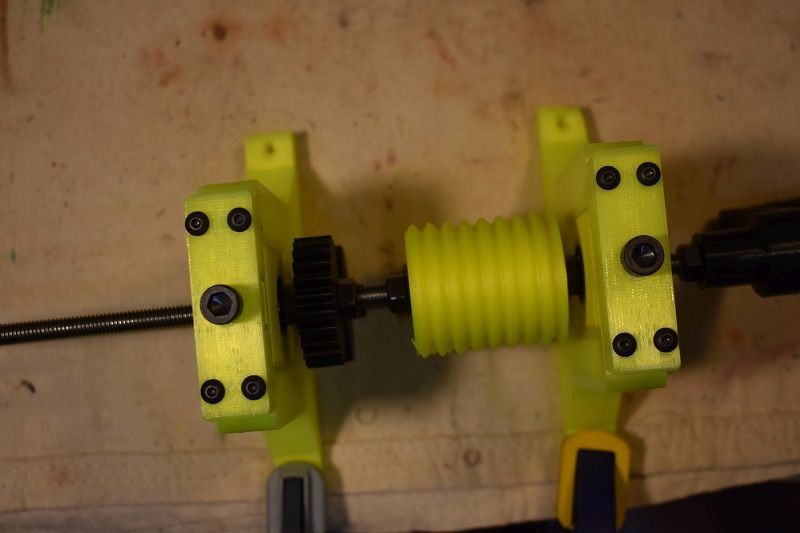

Pete, I don’t think the PETG filament I am using will wear out or flex. The paper crimper I have been using is all plastic including the rollers and I have seen no issues with it other than I can’t control the profile. Should the rollers wear out prematurely, I can print new ones or make them out of a different filament such as carbon fiber or even some of the newer filaments that have various forms of metal in them. I have used the carbon fiber before and it works well, but I’ve never used the metal infused filaments so there certainly would be a learning curve. This whole thing may be an experiment in what not to do but at least we’ll all know in the end.

Dan - chipping in here. I was looking to do something very similar, but then I found a press tool on eBay in the G Scale section. You’ve probably seen it. It makes sections about 4" x 7", which would be on the order of 96" x 168" in full scale if you were modeling in 1/24. This is larger than most real-life sheets would be, so I think the smaller pieces actually seem more realistic. He designed this for 36 gauge aluminum, but actually, using a cut-up pop can works pretty well. Search on “Make your own G or O scale roofing” and you can see what it looks like. Added bonus is the sheets come out flat!

Trent

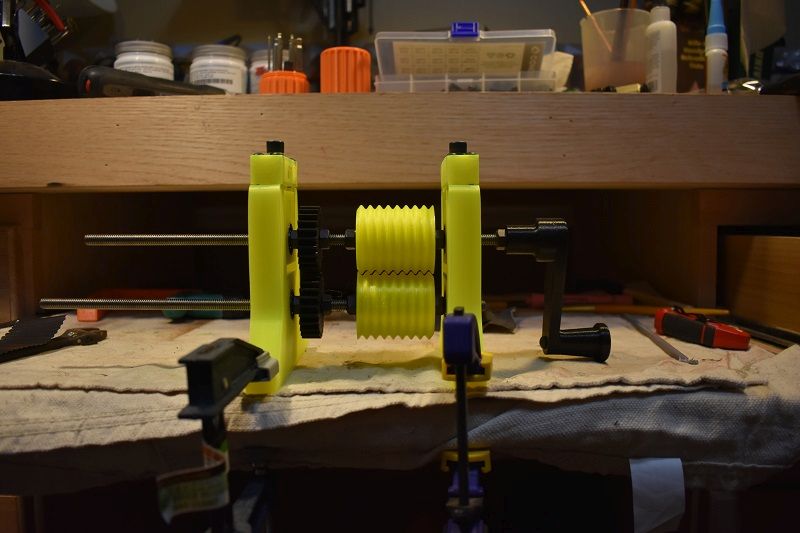

Trent, I’ve not seen that particular press. it looks like it produces a form of standing seam roofing. I’ve consider something similar, kind of a hybrid between the press and the rollers I am attempting to use. Make a bed similar to what is shown on ebay, but instead of using a press, have a roller with a mating profile as the bed and let the roller move on a rack and pinion mechanism along the bed. The press is probably much easier sinc its less moving parts, but it would take a long time to make a large quantity of roofing. Thanks for the information. If this experiment fails, I may look at going the press route.

Trent said:

I was looking to do something very similar, but then I found a press tool on eBay in the G Scale section. You’ve probably seen it. It makes sections about 4" x 7", which would be on the order of 96" x 168" in full scale if you were modeling in 1/24.

I’m wondering how this works? The seller doesn’t specify. The plates look like they are clad in oak so I imagine you could just pound it with a mallet but there are the screw holes so I’m thinking you use bolts and ratchet it down. The holes are missing from one side probably to facilitate loading/unloading.

Dan, I believe this roofing is just corrugated “sinewave” type. Although it does look more “fanfold” than most. Standing seam has the edges raised high and the panels lock into each other rather than overlap. Just so happens I’m looking at putting a metal roof on my home now. Also, what crimper do you have? The only one I’ve seen is the one I have made by Fiskers and has metal rollers.

Dan Gilchrist said:

Trent said:

I was looking to do something very similar, but then I found a press tool on eBay in the G Scale section. You’ve probably seen it. It makes sections about 4" x 7", which would be on the order of 96" x 168" in full scale if you were modeling in 1/24.

I’m wondering how this works? The seller doesn’t specify. The plates look like they are clad in oak so I imagine you could just pound it with a mallet but there are the screw holes so I’m thinking you use bolts and ratchet it down. The holes are missing from one side probably to facilitate loading/unloading.

Dan, I believe this roofing is just corrugated “sinewave” type. Although it does look more “fanfold” than most. Standing seam has the edges raised high and the panels lock into each other rather than overlap. Just so happens I’m looking at putting a metal roof on my home now. Also, what crimper do you have? The only one I’ve seen is the one I have made by Fiskers and has metal rollers.

Dan, I have one made by Marvy and it definitely has plastic or some type of resin rollers. To lite for metal and I sliced a piece off with a hobby knife just to be sure.

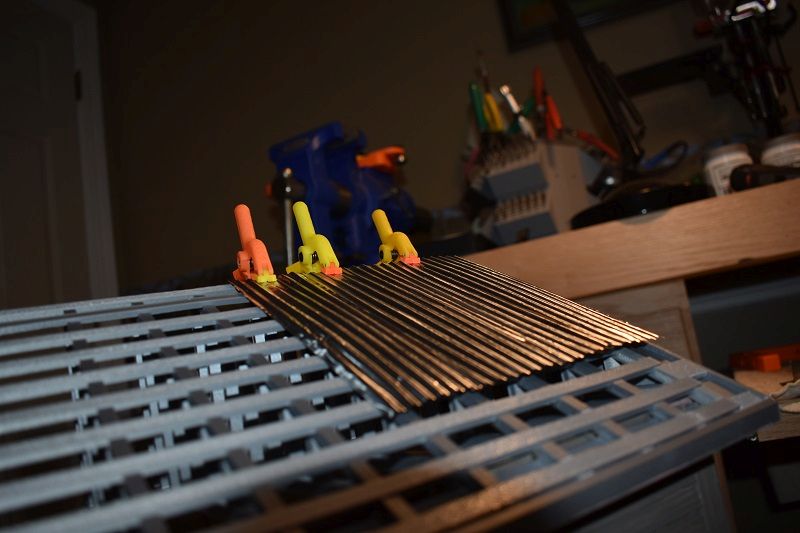

More progress on the crimper. First tin has come off the rollers with some success. Still need to work on the profile to get where I want to be and I must perfect the feeding technique, but it works. Here is the first four pieces of .002" steel shim stock hot off the press … uh, mmmm … rollers …

As you can see the profile is a little out of scale but you can see the rounded peaks and valleys vs the v shaped ones that come off the various paper crimpers. One benefit of this method is, at least in theory, you can make the pieces as long as you want, width is limited to the width of the rollers.

Here is the prototype tool as of now.

Nice you want to sell some? Looks way better than the paper crumpets and probably easier?

Layers of creativity:

“You know, I could make some.”

“You know, I could make a tool with which to make some.”