Has anyone tried a spring switch with Gargraves track and switches? I laid my yard with their turnouts and they basically suck (I love their track though), so now I want to add non-functioning nice switch stands and some kind of throw to replace theirs.

Devon Sinsley said:

OK I think I missed something that you just clarified. So to dumb it down with the above pictures like John’s with the two holes you have operations mode and continuous mode? When I want to run I would move the switch to the off set hole allowing the switch to spring back each time. And then when I want operations mode I move it to the center hole which allows manual operation? If so that is doable. In my layout I would need three of these. One on the two switches on the mainline and one on the mainline of the inner (third Reversing loop).

A little late replying to this.

I wish I was smart enough that the two holes you mention were put there intentionally for the reasons you mention. In actuality, I screwed up. I wanted a rubber/flop-over switch, but my first attempt did not work, so I drilled a second hole. I don’t know if it would work as a spring switch in the other hole as illustrated.

Daktah John said:

I wish I was smart enough that the two holes you mention were put there intentionally for the reasons you mention. In actuality, I screwed up. I wanted a rubber/flop-over switch, but my first attempt did not work, so I drilled a second hole. I don’t know if it would work as a spring switch in the other hole as illustrated.

Well I was actually referring to John C and his picture but I figured yours was the same. So you messed up and moved the hole to make yours operate as a flop/rubber switch but have not experimented to see if it would work as a spring switch. I wonder what the outcome would be as John C says he can switch between modes of operation by changing the hole. If I can only do one or the other I would choose flop/rubber. But if I can have both options by having two different holes and just moving the spring that would be better.

It might, but since I use these in a stub-end yard there would be no point in having them spring.

As I said before, outdoors I just use the stock Aristo manual throw and they operate fine for me as spring switches. If alternating directions through the loop is not a top priority I’d give that a try before you try and make something different work - BUT, for the alternate routes the flop-over or rubber switch would be the way to go.

Personally I would double track that section and put in a crossover, single or double. Then when you want to just run there would be no need to throw any turnouts.

Doing parallel track with a double cross over is certainly an option and one I will strongly consider. There is room to do it and would add additional interest. But these flop switches seem simple enough and would effectively do the same thing with the added bonus of alternating how the train travels the loop. Lots of time to think about it.

I am glad I started a year in advance working out the details of my track plan. It will take at least that long to develop a solid track that can be thrown away next year when I decide to start building and changey mind. Isn’t that how it works.

You should get together with brother Bart. He’s changed his track plan a gazillion times in the last five years. (http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif)

Steve Featherkile said:

You should get together with brother Bart. He’s changed his track plan a gazillion times in the last five years. (http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif)

Honestly I can see this being a problem. I could see where you fuss and tweak and mess with it and never actually build it. I don’t want to be that guy. But I also am the type to analyze it to death so that I don’t do something I regret later. Fine line. I wish I was one of those get track down kinda people but I have a vision (its usually blurry) and I want to at least try to meet it.

Devon,

Or you could say you are a man of words rather than action. (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-innocent.gif)

I had to use the the spring/rubber method (shut up Rooster) I tried using the wire shaped as a v and no matter what I did I can not get the rails to go snug. For now Im using the spring method where wire is placed along side the rails and a small screw is screwed into the outside of the ties. Dave Mayards method. It works fairly well but the lighter cars still have some problems. I still have to play around with this.

Joe Zullo said:

Devon,

Or you could say you are a man of words rather than action. (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-innocent.gif)

No I don’t ever want to say that. Unfortunately, a few times in my life I became just that when it came to Model Railroading. Since moving to this house I tried and HO layout that didn’t pan out and had an N layout that was running but not complete and had to be taken down to make room for children. I can’t promise it will happen by a given date but I am determined to have my Garden Railroad. For now I have to be content with making stuff to go on that eventual layout. My wife says next year I can make a sincere effort to get the ball rolling.

Devon Sinsley said:

Joe Zullo said:

Devon,

Or you could say you are a man of words rather than action. (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-innocent.gif)

No I don’t ever want to say that. Unfortunately, a few times in my life I became just that when it came to Model Railroading. Since moving to this house I tried and HO layout that didn’t pan out and had an N layout that was running but not complete and had to be taken down to make room for children. I can’t promise it will happen by a given date but I am determined to have my Garden Railroad. For now I have to be content with making stuff to go on that eventual layout. My wife says next year I can make a sincere effort to get the ball rolling.

Devon,

In that case my advice is to keep building. You can always dream while you are building. (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-smile.gif)

Joe,

For me the joy is and always has been the building of stuff. Even in the abandon HO I still have kits and scratch built stuff I tinker with that wil eventually be a static display. Even if my adventures in Large scale are nothing more than static displays I am really enjoying building them.

But the nicest part of Large scale is the local club where I know that up until I do get my own layout I will always have a place to run. So building away I am.

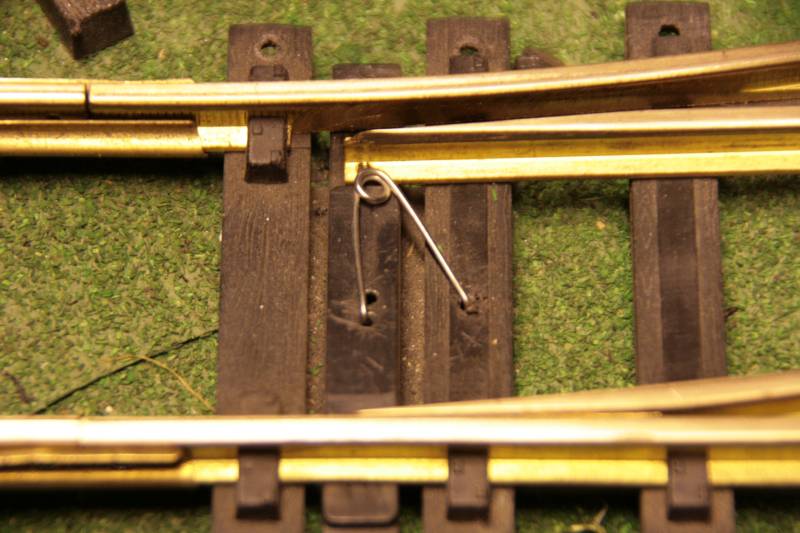

With the “rubber” spring method, the whole idea is the safety pin pushes the two holes apart causing the points to snap one way or the other.

Either a wheel flange or a bare toe switches the points easily. I’ve used both methods, but haven’t had track of my own down for many years.

Good morning Tom, welcome to LSC. Your picture (with appropriate credit) was posted on page one of this 3 page thread. Have some coffee and a doughnut on me! (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif).

Greg